Detailed Product Description

| Style: | Horizontal | Application: | Household, Industrial, Auto |

| Components: | Techmation, Schneider, Vickers | Control Method: | Automatic, Auto, Fully-automatic |

| Material: | PE, PVC, ABS | Mold Cavities: | 10 Cavities, 12 Cavities |

| Working Principle: | High Speed, Hydraulic | Clamping Force: | 328tons |

Double Colour Hydraulic Plastic Injection Molding Machine For ABS Products

Quick Detail:

HI-G328 Plastic Injection Molding Machine is for normal type plastic material injection, e.g. PC, PP, PE, Nylon, A.B.S. PVC etc., this machine is with clamping force 328tons, there are three available screws, the corresponding real shot weight 875g, 1010g, 1160g. This machine is mainly used to produce small, middle&big industrial parts, household appliances and other plastic products.

Description:

HI-G328 Plastic Injection Molding Machine is the type of fully-automatic machine, being provided with high efficiency, high reliability, high speed, low noise, low power consumption and other advantages.

Machine main components adopt world famous brand, e.g.:

? Controller:TECHMATION (TAIWAN),

? Low voltage contactor: SCHNEIDER(FRANCE),

? Low voltage air switch: SCHNEIDER(FRANCE),

? Proportional Valve: Dofluid HNC(TAIWAN)

? Oil pump: VICKERS(USA)

? Directional Valve: VICKERS(USA)

? Induction travel switch: OMORON (JAPAN)

? Inductor potentiometer: FORT(USA)

Specifications:

HI-G328 Technical Parameters

HI-G328 | Optional Parameters |

TECHNICAL PARAMETER TABLE | Unit | A | B | C |

INJECTION

UNIT | SCREW DIAMETER | mm | 65 | 70 | 75 |

SCREW L/D RATIO | L/D | 21.5 | 20 | 18.7 |

SHOT VOLUME(THEORETICAL) | cm3 | 1128 | 1308 | 1502 |

INJECTION WEIGHT(PS) | g | 1026 | 1190 | 1367 |

INJECTION PRESSURE | Mpa | 195 | 168 | 146 |

INJECTION RATE | g/s | 245 | 285 | 327 |

PLASTICIZING CAPACITY | g/s | 50 | 60 | 71 |

SCREW SPEED | rpm | 0-160 |

CLAMPING

UNIT | CLAMP FORCE | kN | 3280 |

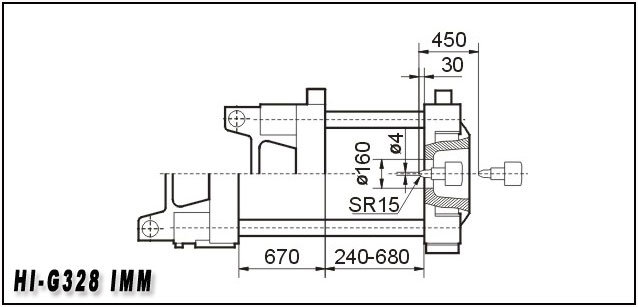

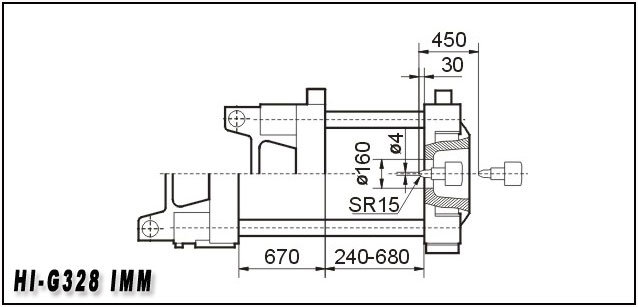

OPEN STROKE | mm | 670 |

MAX.MOULD HEIGHT | mm | 680 |

MIN.MOULD HEIGHT | mm | 240 |

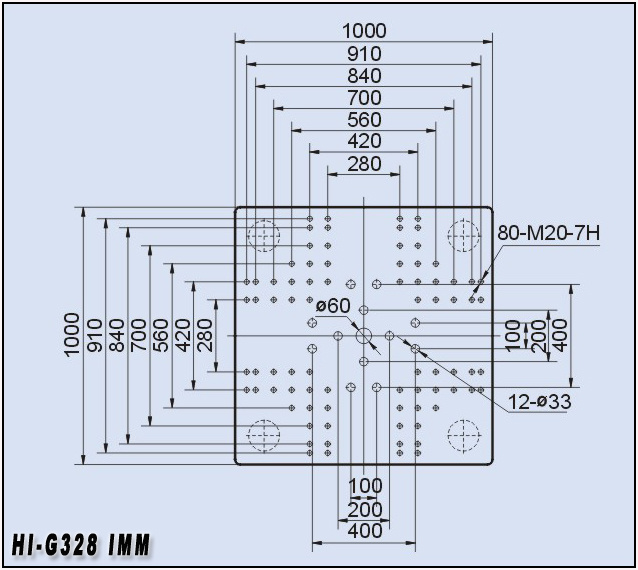

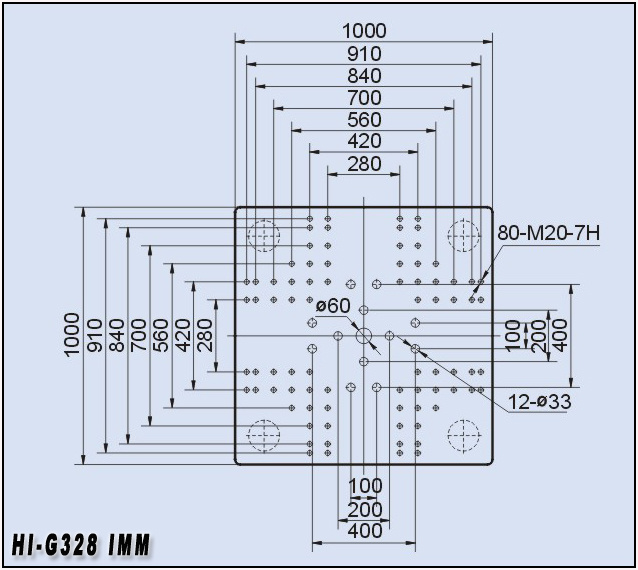

SPACE BETWEEN TIE BARS | mm | 660×660 (W×H) |

EJECTOR FORCE | KN | 65 |

EJECTOR STROKE | mm | 160 |

GENEREL | EJECTOR NUMBER | n | 13 |

PUMP PRESSURE | KW | 16 |

PUMP MOTOR POWER | KW | 37 |

HEATING POWER | KW | 18.5 |

MACHINE DIMENSION | m | 6.9×1.7×2.5(L×W×H) |

MACHINE WEIGHT | T | 12 |

Hopper Capacity | L | 50 |

Oil Tank Capacity | L | 730 |

Applications:

HI-G328 Plastic Injection Molding Machine is for small,middle &big industrial parts, household appliances and other plastic products, material PC, PP, PE, Nylon, A.B.S. PVC etc., suitable plastic products weight 15g-1160g, mold cavity can be: 1 Cavity, 2 Cavities, 3 Cavities, 4 Cavities, 6 Cavities, 8 Cavities, 10 Cavities, 12 Cavities, 16 Cavities, 24 Cavities, 32 Cavities, 48 Cavities,

Competitive Advantage:

1. Heaters adopt ceramic, the using life is double than stainless steel.

2. Machine with oil filter system to ensure hydraulic oil clean , to prolong action valves using life.

3. The machine equipped with 7 inch colorful screen controller, brand Techmation from Taiwan, the controller is with several languages include English, French, Spanish, Portuguese, Russian, Arabic etc.

4. The machine equipped with hydraulic protection

5. The machine equipped with double Hydraulic pulling device

6. The machine equipped with double Air Ejector

7. The machine equipped with single slots on the mold plates

Hisson Plastic Machinery Co., Limited was founded in 1996, which located in Ningbo, a harbor city of eastern China.

We supply high quality plastic injection molding machine, PET bottle blow molding machine, extrusion blow molding machine and various kinds of plastic molds.

Our injection molding machines are exporting to many countries include European countries, Australia, Middle East, Afraica etc., now energy saving is popular, more than 60% of the machines we made are servo motor machines.

In PET bottle field, we have abundant experience, we have special PET preform injection molding machine, PET preform injection mold, semiauto and automatic PET bottle stretch blow molding machine and blow molds, we have 2-cavity, 4-cavity and 6-cavity automatic PET bottle blow molding machine. We provide 2D and 3D design service for PET preforms and PET bottles, according to samples, design draft or only idea.

We serve for all clients include agents and final users, we provide Turkey solution of complete production line, the auxiliary equipment we choose are from top grade manufacturers.