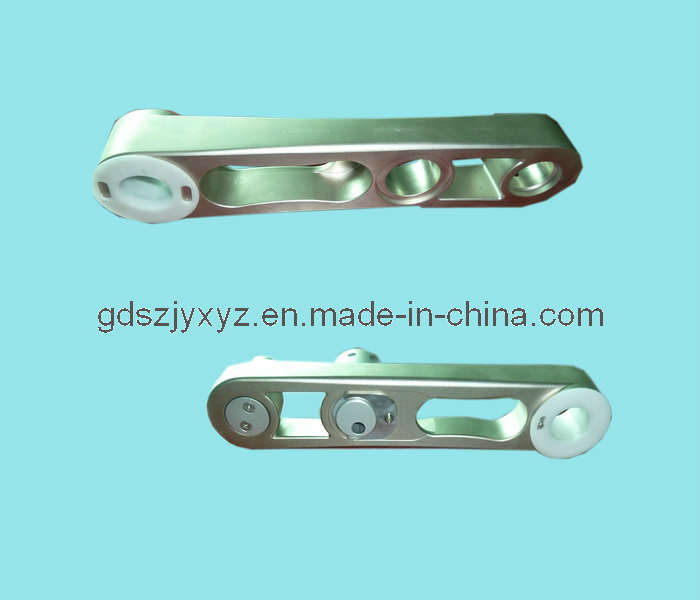

Aluminum die casting Anesthesia Machine bracket

A. We have mold design group

B. More than 10 years die-casting experience

C. Certificated: ISO9001: 2008 SGS

D. Mold material: Japan SKD-61

E. Mold life: 60, 000~100, 000

F. Mold leadtime: 20~30days

1) ISO9001: 2008 certificate

2) Material: A356, A360, A380, ADC12 and so on

3) Product weight: From 0.05kg to 20kg

4) Applied software for specification drawings: PRO/E, Auto CAD, Solid Work; CAXA, UG, CAD/CAM/CAE

5) Surface finish: Sandblasting, painting, polishing

6) Machining equipments: Two-sided boring machine, linear cutting machine, milling machine, drilling machine, combined-lathe and various specialized lathes

7) We also provide OEM service for all series of products.

We can cast and process any type of iron casting products according to the drawing and samples provided by the customers with excellent quality and competitive prices.

As an experienced manufacturer, we assure you the quality!

|

ITEM |

Step |

|

1 |

Received Inquiry |

Analyse Customer requirement and drawing with specification on time |

|

2 |

Quote within 24 hours |

Include payment and mould material product material , warranty delivery time, shipment ect. |

|

3 |

Send customer Schedule with in

24 hours |

Received customer order , Make the plan and arrange to do, then send the schedule to client |

|

4 |

Confirm drawing |

Clients confirm the mould drawing , once get reply will doing soon. |

|

5 |

Prepare material |

According mould drawing to prepare mould base , inserts and pins. |

|

6 |

Making mold about 25~30days |

Machining mould base , cavity insets and core insets, even slide block by CNC, EDM, wire cutting, surface polish and other treatment, finaly assemble. |

|

7 |

First sample and dimension will be finished with 1~3days |

Make samples and measure all dimensions according to drawing , make the dimension report , if all the dimension within tolerance , We will send dimension report to customer with samples. |

|

8 |

Customer confirm samples |

Approve the samples |

|

9 |

Delivery |

Shipment to customer' s country |

Shenzhen Jinyuanxing Metal Die Casting Product Co., Ltd.Is a specialized in all kinds of zinc/aluminum die casting molds and all kinds of precision parts.We are mold designer, Offer additional services( machining, polishing, deburring, sanding, drilling, tapping and so on )To meet our customer's specifications.We also supply all kinds of surface treatment(e-coating, e-piating, anodizing, power coating, sand blast, chrome plating etc.)Now the factory is with 7, 000km2, and a staff of nearly 300 members and workers, among which there are 15 engineers and over 50 senior technicians, who can make 3D designing and technical drawings with CAD/CAM/CAE according to our customers' requirements, and use CNC Processing Center, EDM center, 3-coordinate measurer, NC imitating milling machine, large precision EDM, high-speed milling machines, spot machine, wiring machine and so on.

The major production including automotive, Motorcycle accessories, bicycles, electriocars accessories, electrical appliances, computer accessories, industrial communication, lighting, motor bracket, electric equipment, security accessories, monitor accessories, cooling equipment and other products of zinc/aluminum die casting.And we are happy to co-operate with customer who need to do OEM products by using aluminum/zinc alloy material.

By enhancing 7S management mold and strive to achieve the company "adhere to the study, integration, and win-win" business philosophy, and thus achieve "high-quality, high efficient, truly customer satisfaction" business purposes.We are strictly following the operation rules in the ISO9001:2008 Quality System to constantly procure advanced testing and manufacturing equipment and to develop all kinds of quality training, thus having effectively provided a very strong guarantee for satisfying customer requirements.