Item: Description

Mould Material: P20, 718, 2738, NAK80, S136, SKD61 etc.

Mould Base: LKM, HASCO, DME

Mould Cavity: Single/Muliple

Mould Runner: Hot/Cold

Design Software: UG, PROE, CAD, Solidworks

Mould Life: 300, 000-2000, 000 shots

Material Supplier: ASSAB, BOHLER, SAARSTAHL, DAIDAO, LKM

Hot Runner Supplier: YUDO, HASCO, HUSKY, Mould Master

Plastic Material: PP, PC, PS, PE, PU, PVC, ABS etc.

Delivery Time: 15-60 Days.

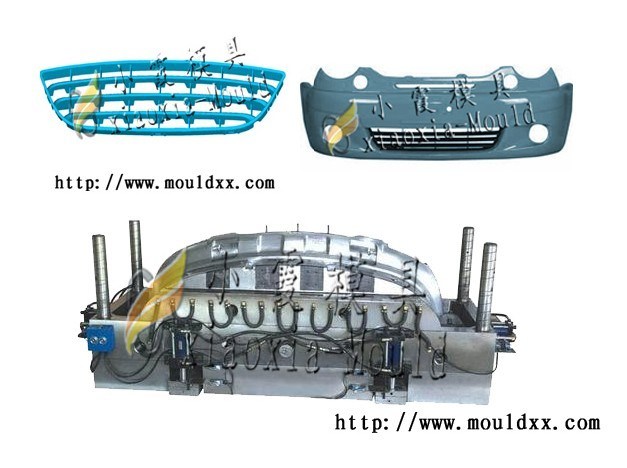

Mold

Mold cooling system design: The cooling system design is a more cumbersome, namely to consider the cooling effect and cooling uniformity, but also consider the overall structure of the cooling system of the mold cooling system to determine the specific location and size; Key positions such as moving the cooling mode or inserts; Side of the slider and the side core cooling; Cooling component design and selection of standard components cool. Our company started in the mold design to analyze the range of issues, tooling approach using recycled water in every part of the mold flow, reducing the cooling time of injection time, improve production efficiency and greatly reduce production costs.

Maintenance of the mold:

Mold maintenance is more important than the mold maintenance, mold maintenance more times, the shorter its life; And tool maintenance, the better, its life will be longer. Three main points mold maintenance; 1. Mold maintenance: Various moving parts, such as thimble, the line position, guide post, guide sleeve refueling, Mold surface cleaning, carrying water of the sparse channel, which is mold to maintain every day. 2. Regular maintenance: Regular maintenance, including routine maintenance and also pay to clean up the exhaust slot, trapped exhaust gas burning black level increases, damage, wear and tear parts of correction. 3. Appearance and maintenance: Die embryo outside the paint coating to prevent rust, the next mold, scheduled to die dynamic model should be coated with anti-rust oil, mold should be kept tightly closed to prevent dust from entering the cavity.

Mould Factory Taizhou Huangyan Xiaoxia. Specialized processing and production of various plastic molds, (plastic injection mold, blow mold, pipe fitting mold), plant processing equipment, use of advanced CAD / CAE / CAM / technology development and design of all-digital tools, combined with ten years experience in mold design and manufacturing and product development experience. Integration of advanced design, Zhejiang University concept, so that my company's technological level and quality of the mold have been fully guaranteed. The company has a professional team of ten senior product development engineer for many years for your new product design and efficient service for your product development to provide a comprehensive solution. The company mainly produces, fitness equipment, mold, commodity mold, electrical, electrical mold, Auto parts molds, pipe fitting mold and other kinds of plastic mold. Factory to excellent quality, reasonable price, advanced management, imports of production equipment, superb production technology, according to the products you need to design, manufacturing.

Zhejiang taizhou huangyan xiaoxia mold factory located in taizhou, zhejiang huangyan mould town. Plant covers an area of 8000 square meters, the factory 20 kilometers north of taizhou airport, 1 km south high-speed exit, east to the railway station 5 km, 2 km east of the terminal huangyan, transportation is very convenient. Full speed away from Shanghai (4 hours), wenzhou, ningbo, jinhua full speed (2 hours). Taizhou, a beautiful environment, economic development, transportation is very convenient.

Mould factory taizhou huangyan xiaoxia. Specializes in processing various plastic molds, (plastic injection mould, blow mould, pipe fitting mould), plant processing equipment, using advanced CAD / cae / cam / technology, digital design and development tools, combined with 10 years experience in mold design and product development experience. Integration of advanced modeling, zhejiang university design, so that my company's technical level and quality of mold have been fully guaranteed. The company has professional personnel, 10 senior product development engineer for many years, new designs for your products and efficient service for your product development to provide a comprehensive solution. Our main products, fitness equipment mold, commodity mold, electrical electrical mold, auto parts molds, pipe fitting mold, and other plastic mold. Factory to excellent quality, reasonable price, advanced management, imported production equipment, exquisite workmanship, according to the products you need to design, manufacturing.

Our sincere commitment is: Honest and trustworthy, mutually beneficial and win-win. Our business philosophy; Excellence, improve the quality of service.

Guidelines for our work. "adhere to industry standards, and create time fine, the pursuit of excellence, striving to industry leading. Our standard: People-oriented, simple and strict. Our goal: Scientific and technological innovation. Management practices, our management system core; " produce high quality molds, provide perfect service "is our commitment.

We sincerely welcome friends to our company, research business. Experience the "honest and trustworthy, mutual benefit and win-win" connotations. Select "xiaoxia die", is to choose the best technology and the integrity of win-win situation, to bring your business a solid quality, business continuity, and harmonious development, and unlimited business opportunities.