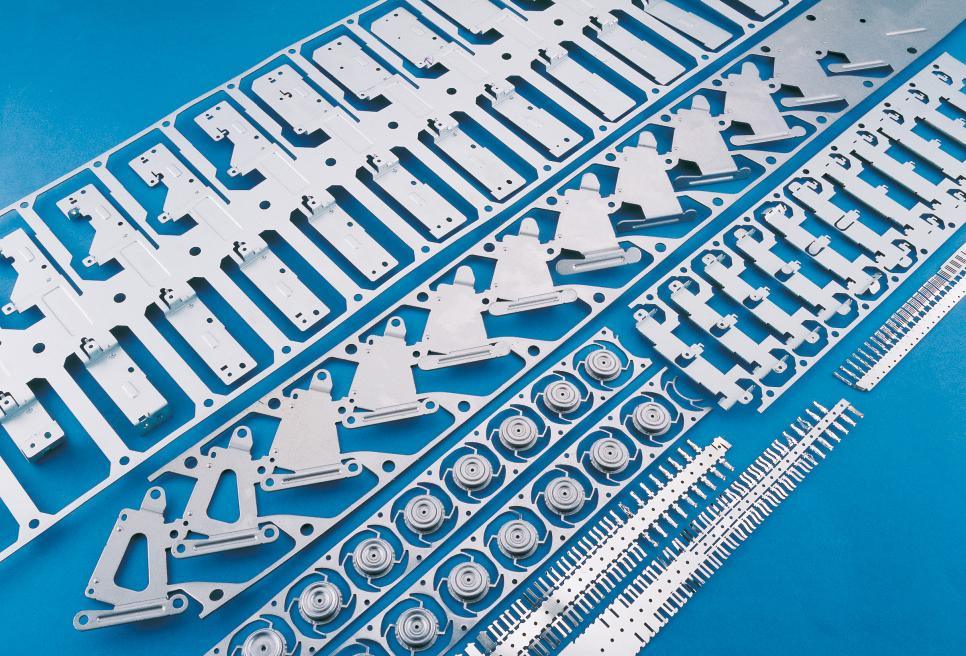

Stamping Die Maker With 18 Year's Experience,

Our Auto Parts Stamping Die Owns Below Superiority:

1) Precision Stamping Die Tolerance: +/-0.002mm,

2) Certification: SGS, ISO9000-2008,

3) All Precision Mould, Stamping Die, Injection Mould, Progressive Mould, Cold Heading Die, Hot Forging Die Are Available,

4) Customized Specification For Stamping Die Are Welcomed,

|

Material For Auto Part Stamping Die: |

SKD, SKH, SKS, SK, HSS-PM, or as customized |

|

Applied Software: |

PRO/E, ACAD |

|

Application Field: |

The stamping die is for auto parts, our precise products applied in: electronic device, medical machinery, auto accessories, aerial device |

|

Lifetime: |

The stamping die can work for 20, 000, 000-50, 000, 000pcs products |

|

After Service: |

Any question replied within 12 hours, giving positive solution within 24 hours |

1. Company introduction_Kingtiger

Kingtiger Metal products Co., Ltd. Was found in 2007. LED by engineers who have more than 20 years experience of mold design, it is just becoming one of the leading engineering and manufacturing companies for metal products in China now. We specialize in a wide range of processes including precision mold/die development and manufacture, precision CNC machining, sheet-metal stamping / fabrication, and assembly of metal parts etc.

Kingtiger relies on total quality management programs and statistical process control in all stages of engineering and manufacturing, which can ensures product quality as well as dimensional and metallurgical consistency.

Our capabilities:

Either through customer's concept, sample or drawing, our engineering team can find the most reliable, cost-saving and quality-assured way to satisfy customers to the utmost, after their thorough evaluation and verification. Equipped with all kinds of testing and measuring devices, such as: 2D Measuring machine, 3D Measuring machine, projector, aging tester, salt-spray tester, Vickers / Rockwell Hardness tester, spectrum analyzer etc., we do full inspection for every single out-going products or molds, we only deliver when customers are satisfied. We will respond to every inquiry and handle exception cases with fastest way and most sincere attitude.

Main business:

Computer industries

Automotive industries

Electric and electronic industries

Home-appliance industries

High-end hardware product industries

We have demonstrated uncompromising commitment in offering superior products and excellent services.

Main Facility As Below:

We own 30 sets stamping machines, 8 sets CNC turned machines, 6 sets CNC machining machines, 10 sets automatic lathe machine, and other second assistant machines, and an assembly shop

Our Products Own Below Superiorities:

1) Producing Process Based On The SPC,

2) RoHS Is Available For Electronic Parts,

3) All The Finished Products Should Be Fully Inspected Before Delivery,

4) Our After Service Obeys That: Replied Positive Solution Within 12 Hours,

5) OEM And Specification Is Welcomed,

Our sales structure: 65% export, 35% home-market.

Foreign market: North America, South America, Eastern Europe, Western Europe, MID East.