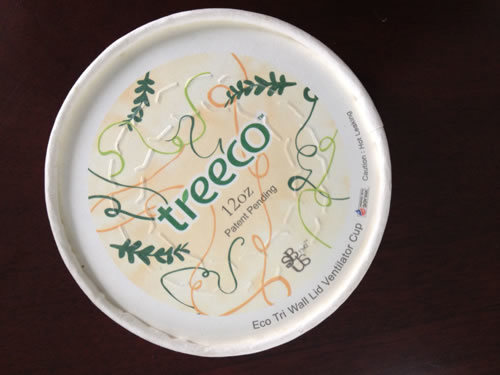

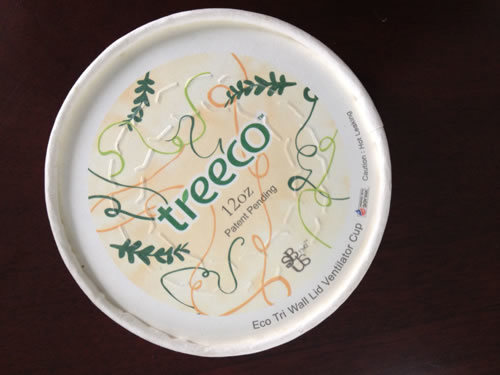

Automatic paper lid forming machine is also called automatic paper cup cover machine or automatic paper lid making machinery. It is mainly used for manufacturing covers with different shapes, such as ice cream cup lids and jewellery box lids. Its main parts include gearbox, reduction gear and American hot melt adhesive box. It adopts advanced molding technology to complete a variety of molding processes and to completely replace the manual procedures. The automatic paper lid forming machine is characterized by stable operation, low consumption and high production efficiency. It can be operated by one person that greatly saves labor. Besides, this paper lid making machinery can save raw materials and is easy to replace moulds. Our company makes use of wooden cases for sea transportation.

Parameters of Automatic Paper Lid Forming Machine

Specification top diameter: φ65-φ128, height: 15-30

Production Speed45-50 pcs/min

Configured Voltage380 V

Configured Power6 kW

Total Electricity Waste4 kW

Glue Box ConfigurationHot melt adhesive box from American Dynatec

Gas Consumption0.12 m3/min, 4 kg/cm2

Weight1200 kg

Dimension(L × W × H) 2265 mm × 1898 mm ×1575 mmAdvantages:

The machine itself has two sets of standard mechanism, one is used to set the bottle body, a bottle mouth is set. The stainless steel structure: made of stainless steel SUS304, simple structure, beautiful appearance, easy to clean, the water does not rust. The unique label positioning device: to ensure accurate positioning sleeve labeling. The use of modular design, mold the chopstick control, precision, high-speed sleeve. The use of high-quality touch screen operation section, implementation of operating, convenient, fast. The high degree of automation, simple to use, only one person is needed to operate, easy to maintain. The Panasonic servo system, servo control system to ensure high speed, sets of standard error free.

Technical data:

Electrical Source | Single phase220V |

Power | 5KW |

Dimensions | 3200×1180×2000(mm) |

Packing Speed | 100-350BPM(MAX) |

Bottle Dimension | 28-125*300(H)mm |

Label Thickness | 0.035-0.07mm |

Applied Material | PVC PET OPS |

Applied Label Thickness t | 30-250mm(MAX) |

Main Machine Weight | 700KG |

Motech is active worldwide in Packing Machine. The company develops, produces and sells innovative products and services that help improve the quality of power. Motech's strategy focuses on accelerating profitable and innovative growth of the company's specialties portfolio. The key drivers of this strategy are market-driven growth and innovation plus an increased presence in emerging economies.

China-Motech has been providing automated bagging equipment; Bag packaging machinery; Capping Machine; Carton Machine; Coding and Marking; Complete Filling System; Conveyer Equipment; Filling Equipment; Packing Machine; Palletizer; Labeling Machine; Sealing Machine; Shrinking Wrap Machine; Weigher; Metal Dectector etc for over 20 years. Our solutions embody innovation through research and development, reliability through top of the line components and superior engineering concepts, and a clear understanding of our customer needs and expectations. We have built our business and stake our reputation on delivering on our promises and honoring a long standing commitment to after market support. Our sharp focus has allowed China-Motech to design superior automated bagging systems specifically built for the followingindustries: Seed; Feed&Grain; Salt; Minerals; AggregateProducts; Pet Food; Chemical

Production & MarketingBoasts its 90000 square meters production base and owns complete modernized metal cutting equipment, equipped with advanced Solidworks 3D mechanical design and Computerized Simulation Test System, Hsien has cultivated a professional technology and after-sales service team, and successfully achieved ISO9001: 2000 Quality Management Certificate and EU CE Certificate.

Till now, we have formed a whole production chain with main products: Packing Machine; Sealing&Filling Machine; Labeling Machine; Shrinking Machine; Precision sliding table saw; Edge banding machine; Trimming machine; Automatic postforming machine; Glass Double Edger; Glass Drilling Machine; Glass Washing Machine; Glass Beveling Machine; Glass Sandblasting Machine; Glass Drilling Machine; Glass Laminating Machine; . Products cover more than 40 models of 3 major series: Packing Machine series, wood working machine series, and glass machine series. Advanced technology content, high reliability, low operation and maintenance cost have enabled our products to take the leading position in the field.

Our products have been exported to more than 130 countries and are widely used in global food and construction industry. Being innovative and perfect is our incessant pursuit, and also our vigor source of energy and harmony. We will continously create better products and better services, and always bring more value for our customers.