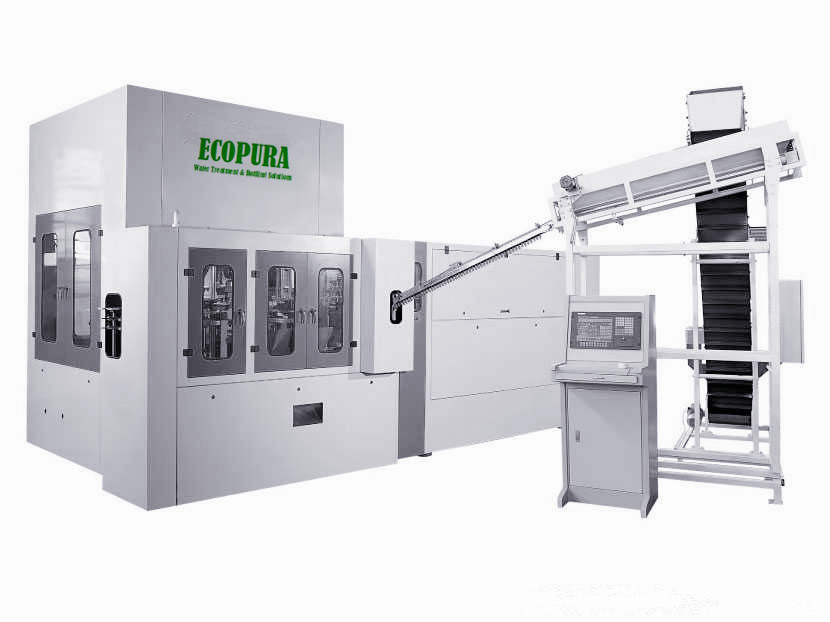

EcoPura Engage in Blow Molding Machine, Stretch Blow Molding Machine, Bottle Blow Molding Machine, Blow Moulding Machine, Bottles Blowing Machine, Blow Molding Machinery, Bottle Making Machine, Blow Moulding Machinery, Blowing Machine, Moulding Machine, Molding Machine, Blow Bottle Machine, plastic machine, blow machine

A. Brief Introduction

ECP-R6 (6 stations, one mould in each station), 10200 Bottles/Hour, 1800 bottles/station/hour.

ECP-R8 (8 stations, one mould in each station), 14400 Bottles/Hour, 1800 bottles/station/hour.

ECP-R10 (10 stations, one mould in each station), 18000 Bottles/Hour, 1800 bottles/station/hour.

ECP-R6, ECP-R8, ECP-R10, ECPR12, ECP-R16 is the most stable two-step fully automatic high-speed rotary PET stretch-blow moulding machines(reheat). The capacity of the products is from 0.25L to 2.0L. It can blow pet bottles for different use: Carbonated, mineral water, milk, beer, oil, hot filling tea, and other drink packing containers, which is made of plastic of crystalline type, such as PET, PP etc.

ECP-R series has adopted original heating and blowing technics, by which the automatic blowing machine series have achieved in powerful productivity but very reasonable price.

B. Machine Construction

B. 1. Preform feeding and loading unit

The design of the recycling unit prevents the preforms from getting bound up in the unscrambler. The star wheel design of the feeding unit provides the lowest possible changeover times for switching to different perform sizes.

B. 2. Linear Oven

A mandrel capable of turning 180 degrees guarantees uniform neck section during the heating. A unique oven ventilation system enables the DMK-R series blower to handle various difficult applications easily.

Power saving: Heater is fixed with link of short section(43.8mm), which assures to heat more performs with the same heating length. In this way, it saves electricity of 25%.

Water cooling plate: Cooling bottle neck avoid neck deformation during heating.

Infrared heat lamps:

A. Each lamp is individually adjustable;

B. Lamp gripper is adjustable as angle changes;

C. Lamp rod is adjustable in length, which is good for bottom heating;

B. 3. Preform and bottle transfer wheel

The new DMK-R series utilizes a classic double cam telescopic gripper system, this guarantees reliable movement, and easy maintenance.

B. 4. Molds and Mold Carriers

The mold carrier utilizes a shell blow mold design; This reduces the changeover time for different blow molds. The Mold carriers accommodate all shell type molds from conventional blow molding machines, this saves time and expense for bottle producer. Moreover, the reliable quick locking system maximizes the performance of the mold carriers.

B. 5. Blowing Station

A changeable cam for the stretching curve guider guarantees the form quality for different size bottles. Monobloc blowing valves achieve the fastest and most consistent blowing process possible. Bottle necks are protected during the blowing stage by a specially designed sealing unit.

C. Options:

C. 1. PID heating zone system (Option)

Within this system, an infrared thermometer automatically detects the temperature of the performs and adjusts the temperature of the oven as needed. This automatic adjustment avoids the influence of a temperature difference between day time and night; Also the system can use an additional lamp alarm, this alarm will sound when it detects any broken or aging lamps.

C. 2. Patented Air Recovery system (Option)

We know that most of the production costs for blowing bottles are attributed to generating the high pressure compressed air and applying heat to the preforms. In order to lower these production costs for the bottler producer, Demark Machinery has introduced its patented Air recovery system. This system recovers up to 30% of the final high pressure blowing air and ultimately lowers the cost to produce bottles.

|

ITEM |

UNIT |

ECP-R6 |

ECP-R8 |

ECP-R10 |

|

For Cold Filling |

For Hot Filling |

For Cold Filling |

For Hot Filling |

For Cold Filling |

For Hot Filling |

|

Productivity(500mL) |

bottle/h |

10200 |

7200 |

14400 |

9600 |

18000 |

12000 |

|

Volume |

L |

0.2~2 |

0.2~2 |

0.2~0.65 |

0.2~0.65 |

0.2~2 |

0.2~2 |

|

Material |

|

PET |

PET |

PET |

PET |

PET |

PET |

|

Max.diameter |

mm |

120 |

120 |

65 |

65 |

120 |

120 |

|

Max.height of preform |

mm |

145 |

145 |

145 |

145 |

145 |

145 |

|

Max.height of bottle |

mm |

320 |

320 |

250 |

250 |

320 |

320 |

|

Power |

|

380V 50HZ |

380V 50HZ |

380V 50HZ |

380V 50HZ |

380V 50HZ |

380V 50HZ |

|

Installation power |

kw |

3 |

3 |

3 |

3 |

4 |

4 |

|

Oven installation power |

kw |

108 |

108 |

112 |

112 |

216 |

216 |

|

Elevator power |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

1.5 |

|

Actual total power |

kw |

37 |

53 |

38 |

55 |

70 |

103 |

|

Cavity |

|

6 |

6 |

8 |

8 |

10 |

10 |

|

Blowing pressure |

Mpa |

3.8~4.0 |

3.8~4.0 |

3.8~4.0 |

3.8~4.0 |

3.8~4.0 |

3.8~4.0 |

|

Blowing air flux |

m3/min |

6 |

16 |

8 |

20 |

10 |

24 |

|

Working air pressure |

Mpa |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

0.8 |

|

Working air flux |

m3/min |

6 |

6 |

7 |

7 |

7 |

7 |

|

Eigible rate |

% |

99.8 |

99.8 |

99.8 |

99.8 |

99.8 |

99.8 |

|

Dimension of main machine |

mxmxm |

2.2x1.8x2.9 |

2.2x1.8x2.9 |

2.2x1.8x2.5 |

2.2x1.8x2.5 |

2.3x3.15x3.1 |

2.3x3.15x3.1 |

|

Dimension of oven |

mxmxm |

2.7x1.0x1.9 |

2.7x1.0x1.9 |

3.2x1.0x1.9 |

3.2x1.0x1.9 |

3.9x1.03x2 |

3.9x1.03x2 |

|

Weight |

kg |

7500 |

8000 |

8500 |

9000 |

15000 |

16000 |

Shenzhen EcoPura Water Equipment Co., Ltd was founded in 2007, specialized in Water Treatment/Dispenser, bottled water/beverage filling line, Blow molding machine & packaging solutions over 18 years experiences, In China, ECOPURA commands more than 60% of Water and Beverage Process Machine market. Covering all segments. Highly acclaimed for their user-friendly, tailor-made designs and customized solutions for various customer needs

As a leading manufacturer, we can supply the following solutions:

1, Water Treatment Solutions based on different raw water quality

Municipal or Mountain water treatment / Brackish Water Purification / Sea water desalting

2, Automatic Bottled Water Production Line

Accuracy filling, position due to PLC application and photoelectricity technology, neck spraying nozzle for cleaning completely, avoid the 2ND pollute. Adjusting and setting data make machine suitable to various bottles.

A)PET 250 ml - 2000ml Bottled Filling Line

B)PET/PP 3 liters - 6 liters Bottled Filling Line

C)5Gallon Bottled Filling Line

3, Blow molding machine with mould design and Post packaging machinery to be fully synchronized with the bottled water filling line.

4, High Quality Water Dispenser with 15years OEM experience for abroad client demand

With the support of advanced technique, mature experienced engineers and customer-oriented after sales service, So far, ECOPURA has close cooperation with hundreds of customers all over the world from USA, Canada, Russia, Mexico, Brazil, Panama, Sudan, Nigeria, Angola, Iraq, Jordan, Indonesia and so on. We won enormous credit by carry out business and confirmation based on carefully understood acts and detailed requirement from every customer.

Providing ' Quality Products, Customized services, Competitive Prices and Timely Delivery', . We are now looking forward to even more cooperation with overseas customers based on mutual benefits, Please feel free to contact us if you are interested in our products, Sincerely welcome to visit our company!