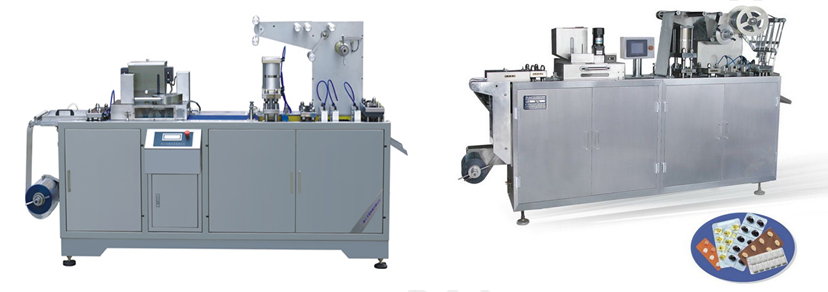

Blister Machine (AZ-01)

| Price: |

US $ 5000-12000/Piece |

| Trade Terms: |

FOB,CFR,EXW |

| Min Order: |

1/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union,Money Gram |

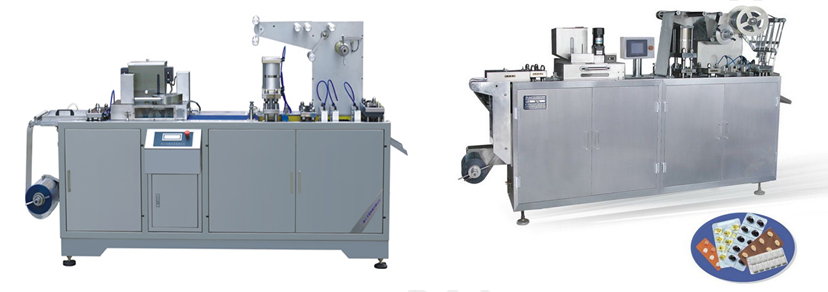

Blister packing machine A. Specifications1. Turnkey project 2. Semi-automatic or fully automatic 3. Customized design 4. CE,ISO,SGS5. High efficiency6. Adopts top brand PLC controller with touch screen displayed in Chinese and English, Frequency inverter for speed control, servo traction, which can ensure the length of blister traction adjustable within the range. B. Main Description1. It is suitable for packaging with paper-plastic in the industrial of hardware, medical equipment, toys, batteries, electronic products, auto parts, commodity, cosmetic, rubber products, dinnerware, and kitchen ware. For example, the injection, syringe, toy car, flashlight, spark plug, toothbrush, lipstick, facial mask, chopstick, shaver, correction fluid, ball-pen, medicine and so on.2. Mainly used for automatic carton of pharmaceutical bottle/blister/soft tube/injection/pillow pack. Can be operated singly and separately or connected to the front/behind relative equipment according to the requirement to improve the production efficiency. It can open the carton, insert the relative product into carton with leaflet, make embossing print on the carton and close the carton by inserting the tongues or by hot melt gule machine automatically.3. Speed-regulated with variable frequency, adopts PLC automatic control system.4. Adopts human-machine interface operating system with automatic indication of packaging speed and counting and the fault causes and methods of operation and maintenance and etc.5. Cartons in different specifications as specified can be implemented on the same machine after adjustment .6. Switchover between manual and automatic operation.7. The instructions can be folded and carton automatically.8. Can make the steel print in 3 rows for batch numbers.9. Automatic inspection system and machine switch-off in case of non-conforming products.10. It can be installed with hot melt adhesive machine as request.(Optional) C. Flow chart PVC Roll--PVC Pre-heating--Blister Forming--Servo Traction--Blister Cutting--PVC Edge Material Collection--Picking Up Blister Tray into Railway Mold--Manual Feeding Products (Automatic Feeding Optional)--Automatic Feeding Paper Card--Tray Paper Heat-sealing--Output D. Main technical parameter

1. With thermal temperature control and test, main machine over loading protect, PVC and PTP packing material position test, feeder material position test , failure automatic debug and alarm, automatic protection and stop running.2. The machine station module type design of level frame, good sight, safe and convenient operation.3. Thermal with contact type, positive press formed, air cushion thermal seal upper and lower net, photo register make your product package better.4. PVC exchange support with bigger type material support, whole roller, which makes the equipment more practicability.5. The special design of moulds in rectangle shape, ladder type fixing, provide much convenience and easy to moulds replacement. All material contact parts adopt high quality stainless steel and aluminum metal, slap-up surface treatment craft.6. Discharging finished product in right order, automatic collection of bad products, auto rewinding of strap material to ensure easy collection.7. Feeding efficiently, reliable and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder)8. The machine has been designed into separated body, which is easily move into lifts or workshops.E. Other models

1. With thermal temperature control and test, main machine over loading protect, PVC and PTP packing material position test, feeder material position test , failure automatic debug and alarm, automatic protection and stop running.2. The machine station module type design of level frame, good sight, safe and convenient operation.3. Thermal with contact type, positive press formed, air cushion thermal seal upper and lower net, photo register make your product package better.4. PVC exchange support with bigger type material support, whole roller, which makes the equipment more practicability.5. The special design of moulds in rectangle shape, ladder type fixing, provide much convenience and easy to moulds replacement. All material contact parts adopt high quality stainless steel and aluminum metal, slap-up surface treatment craft.6. Discharging finished product in right order, automatic collection of bad products, auto rewinding of strap material to ensure easy collection.7. Feeding efficiently, reliable and suitable for many kinds type arrange and irregular feeding,(according to actual product design fit feeder)8. The machine has been designed into separated body, which is easily move into lifts or workshops.E. Other models

| Model | JY-001 | JY-002 | JY-003 |

| Punching frequency | 15-35 times/min | AL/PVC 15-45 Times/min

AL/AL 15-35 Times/min | AL/PVC 20-60times/min

Al/AL15-30times/min |

| Max production capacity | | ALU/PVC 72000-236000pcs/hour

ALU/ALU 40000-100000pcs/hour | AL/PVC 140thousand Grains/hour

Al/Al 75thousand Grains/hour |

| Adjustable scope of Travel | 40-120mm(adjustable) | 30-120mm | 30-140mm(160mm) |

| Max forming area | 140mm*110mm | AL/PVC120mm*240mm

ALU/ALU 120mm*240mm | AL/PVC 260mm*130mm

AL/AL 260mm*130mm |

| Max forming depth | 25mm | 25mm | AL/PVC 25mm

Al/Al 18mm (made to order) |

| Total Power | 3.8KW | AL/PVC 5.5KW

AL/AL 5.5KW | AL/PVC 8.5KW

AL/AL 8.5KW |

| Clean compressed air | 0.4-0.6 Mpa | | Press 0.6-0.8Mpa |

| Air Pump Volume Flow | ≥0.2m³/min | ≥0.2m³/min | ≥0.25m3/min(self prepared) |

| PVC for medicine | 0.25mm-150mm | 0.25mm*250mm | 0.25mm*260mm |

| Aluminum Foil for sealing | 0.02-150mm | 0.02mm*250mm | 0.02mm*260mm |

| Forming Aluminum | 0.15mm-150mm | 0.16mm*250mm | 0.16mm*260mm |

| Overall Dimension(L*W*H) | 2400*575*1560mm | 3650*825*1735 | 4500*760*1620 |

| Weight | 620kg | 1500kg | 1800kg |

F. Accessory equipment and goods deliveryG. Product application H. Spare parts suppliersI. Company introduction

H. Spare parts suppliersI. Company introductionShanghai Junyu Industrial Group is a High-tech enterprise on the fermentation field, is the biggest and strongest comprehensive ability supplier for solvement of fermentation project. And she is also an industrial company with the manufacturing experience more than 30 years.

Shanghai Junyu Industrial Group adopts German advanced technology and complies with domestic customers` requirements to design and manufacture equipment. The production process is superior, easy operated and simple to learn and understand.

These various food produced by the equipment are deeply adored by customers. The equipment with production capacity 1000 to 5000 per year is especially a good choice for township enterprises, verge area enterprises, personal investment for setting up plant, and updating equipment in the plants. The products have been widely sold in China and exported to Europe, America, Africa, Asia etc. Which make us good reputation from our internal and external customers !

J. Advantages of usOur engineer: free direct the installation and operation of the equipments and train operators for customer. Our machine: safe and reliable, efficient and energy saving, easy operating. Our delivery: in time with English operating instruction program. Our after-sale service: timely, professionally K. Products professional certificationL. Pioneer and keep forging ahead with our clients M. We always hold that in the most familiar field Area manager/ Ancy Zhang Mobile: 0086-13774374153 Shanghai Junyu Industrial GroupAD:Room2708, 27F, China Merchants Tower, NO.161 East Lujiazui Road, Shanghai, China. 200120

TEL:0086-21-32020358 Ext817 FAX:0086-21-32020328 Website: www.fruitvegetablemachine.com www.jouyu.com

| Prod Model: |

AZ-01 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size(mm): |

1200*680*480mm |

| Capacity: |

100-1000kg/H |

| Net Weight: |

500 Kgs |

| Gross Weight: |

530kgs |

| Material: |

S.S |

| Packaging Type: |

Cartons |

| Automatic Grade: |

Automatic |

| Packaging Material: |

Plastic |

| Application: |

Hair Care Products |

| Usage: |

Inner Packing |

| Type: |

Packaging Sealing Machine |

| Material Type: |

Bulk Solid |

Owned by Junyu Industrial Group, Shanghai Junyu Internatioanl Trading Co. Ltd., is a company specialized in Exp & Imp. As a high-tech company, Junyu Industrial Group is professional on the research, development, design and manufacture of machinery.

Currently our group main business can be divided into 5 parts:

1). Food Machinery,

Candy machine, chocolate machine, cake machine, biscuit machine, fruit and vegertable processing line...

2). Chemical Industry,

3). Construction Material Machinery,

4). Construction Contract,

5). Know-how Transfer Cooperation.

Our products are categorized into 4 parts:

1)Food and beverage production line, like biscuit equipment, cake machinery, candy machine, fruit and vegetable processing machine and so on.

2)Chemical production line and its know-how transfer, like of soap, detergent and other related chemical.

3)Construction material machinery, like brick molding machine, stone molding machine, sand making machine, steel pipe making machine and so on.

4)Construction contract. We serve customer in a way of turn-key project or general contract. Not only a whole production line is provided, but also part one, like steel structure plant, large chemical storage tank etc.

Up to now, our products have been exported to over 200 countries in 7 continents. In China, Junyu owns 15 machine manufacturing plants located in Shanghai, Jiangsu, Zhejiang, Guangzhou, Shandong, Henan etc., 3 machine installation and project construction companies, and 2 research institutes and after-sale service companies in major markets like Midlle-East, Southeast Asia, Africa, South America etc.

Holding true to providing best design project, best equipment and best professional service, Junyu has been trusted and chosen by more and more overseas customers. Sincerely hereby we are looking forward to our cooperation.