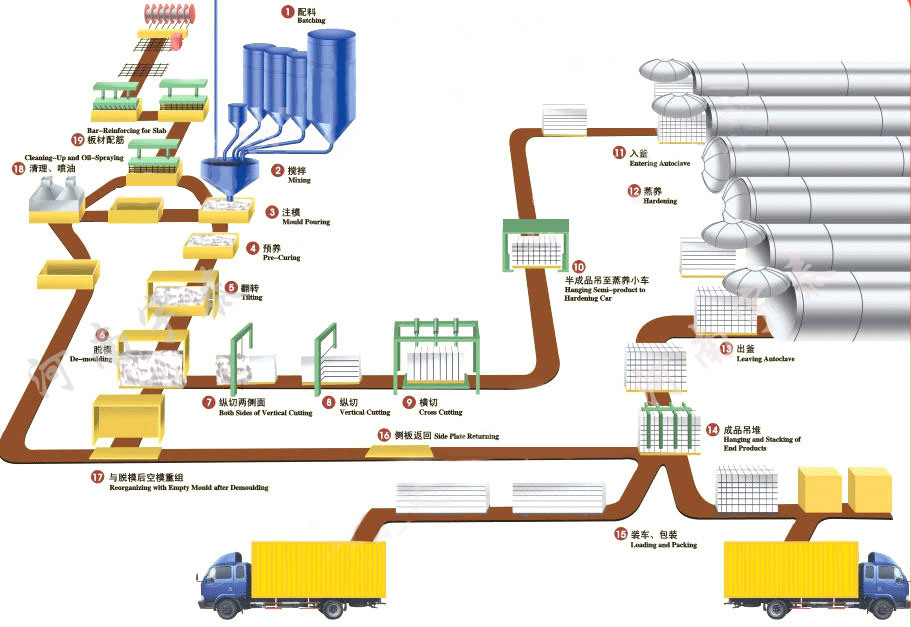

AAC plant contain the cutting machine, ball mill, autoclave, cusher and so on. The autoclave areated concrete plant simple name is AAC equipment, Production Process of Aerated Concrete According to the category and quality of raw material, and the features of equipment, the aerated concrete can be manufactured in different processes. Generally, add water to ash, silica sand or slag and crush them into slurry; Then add powdery lime, cement of right amount, plaster, vesicant, foam stabilizer, and mix and pour it to mould frame; After curing, foaming and hardening, cut it into blocks and boards in different specifications; Finally, transport it into pressure steamer with steam-curing cart, and get the light cellular concrete after steam-curing with high temperature and pressure. Process Flow of an Annual Output 50, 000 m3---200, 000 m3 Aerated Concrete Steam-Curing Production.

Production Engineering of AAC Block:

1. First, dose and match measured raw materials

2. After distributing, feed raw material into pouring mixer to make slurry

3. Through thoroughly mixing, the slurry is poured to mould

4. After pre-curing with a certain temperature & time, the block would reach certain hardness prepare for cutting 5. Tilting hoister would turn over 90 degree of mould

6. Then open the mould & separate it from block, take the block with side plate with cutting cart

7. The block then be cut through the cutter firstly of two vertical sides of block

8. Secondly the horizontal cutting

9. Finally the vertical cutting

10. After cutting, the block is hanged to trolley with side plate by semi-finished product hoister

11. Organizing the cut blocks and put them into autoclave

12. Hardening the blocks under certain temperature and pressure

13. Take finished products out of autoclave

14. The finished product hoister takes the finished product to stock shield

15. Packed for loading

16. The side plate return back by side plate roller

17. Side plate would be organized with open mould

18. Clean the mould and preparing for next pouring

19. Steel bars processing line for slab production

Henan Yigong Machinery & Equipment Co., Ltd. is a modern enterprise engaged in new building-material equipment, metallurge and mineral processing equipment, and it integrates research, development, production, with sales together. The company is located in Zhengzhou city-the transportation junction of China, and was founded in 1978. After 30-year development and evolvement, now the company owns 3 branch companies and 1 machinery research institute. It covers an area of 50, 0000 square meters, of which the modern buildings occupy 15, 000 square meters. Our company adopts new management concepts, scientific management and efficient operation of the system and take part in international competition in the market, painstakingly created high-quality products to repay new and old customers. As a result, it has become a famous enterprise of machinery industry. With many-year accumulation, Henan Yigong has collected rich experiences in production and management, and has brought up a large number of technical staffs and management elites. Through constant introduction, digestion and absorption, the company has developed 100 sets of various large and intermediate equipment, and such workshops as casting, forging, thermal treatment, machinery processing, welding, assembly, and machine repair, etc. The maximum capability of assembly lift is 120t. What's more, it has passed ISO9001.2000 Quality Certification. The enterprise constantly renew its products, which are well-known around the world and widely accepted by customers.

The main products of the company consist of five series:

1. AAC Equipment

2. Stone crusher

3. Mineral Processing Equipment

4. Sand-gravel Equipment

5. Crushing and Grinding Equipment

6. Others

Our products can be divided into 30-odd kinds and 100-odd types. These equipments are widely used in the building-material, metallurgy, corhart, and ceramic industries, etc.

The company possesses the first-class sales team and technical service team, who can provide not only project design, processing flow, and standard or non-standard product design, but also full service, i. e. Before-sale, while-sale, and after-sale services. The company will represent customers with equipment of excellent performance and good quality. At a new development starting point, the company will follow the social resposibilities of respect, mutual help, love, and harmony, and actively participate in the construction of national economy. Guided by the enterprise motto-Good faith is the base, technology is the first, and innovation is the soul, the company will do its best to gain honor for itself, create value for customers, and make fortune for our nation. Lets March forward with Chinese economy hand in hand. Enterprise Culture Motto of Yigong: Good faith is the base, technology is the first, innovation is the soul. Logos of Yigong: To produce first-class products and enterprise with heart and soul. Spirit of Yigong: Innovation, high efficiency, preciseness, and good faith.