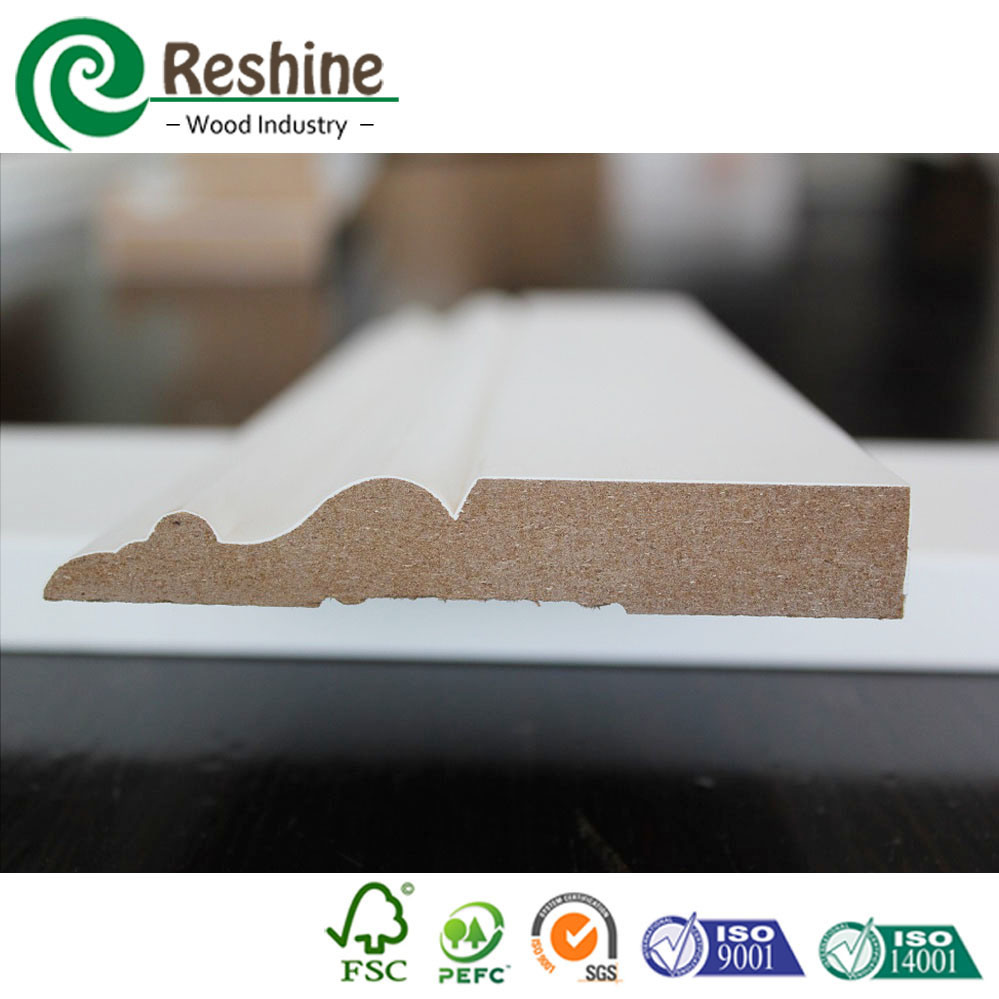

White Coated Mdf Decorative Baseboard Molding

Base information |

| Name | Decorative Flooring MDF Baseboard Moulding |

| Size | 9/16"*4-1/4",9/16"*5-1/4"or as Customized |

| Wood Speices | LVL(Hardwood) / Radaita Pine / Chinese Fir |

| Surface finish | 2 coats Gesso, after sanded to smooth face,then 1-2 coats primed(water based paint) |

| Manufacture technique | Via shape, machining, gesso, sanding, primer and packing etc. |

| Demesion Tolerance | +/-0.3mm |

| Moisture Content | 10%-12% |

| Quality control |

No pith, no permitted machine marks, no fibre tear or skip-dressing, no raise grain,

but must be smooth, sanded finish on all four-faces. |

Package |

Standard packing e.g. Plywood pallet with kiln-dried wood or as consumers' request |

| MOQ | Full container, 1x40GP or 1x40' HQ |

| Dlivery time | Normal 45 days. Details as negotiated for different items. |

| Application |

Ceiling Cornice, Door & Window Casing, Wall, Fireplace,Washboard

/Skirting/Baseboard, Windowsill, Chair Rail,Handrail, Furniture Decoration, etc |

Main Market | Australia,North America,Europe,etc |

Main Profiles for the North American Market Wood Molding:

1. Specification

1) Species: Radiata Pine/Chinese Fir/LVL

2) Moisture content: 10-12% The raw material prior to manufacture should be kiln dried to within the 10-12% moisture content range To ensure stability through the successive manufacturing processes.

3) Specification: Accept customized size and profiles Finger jointing is a popular process used for producing wood moldings, using mechanical (and/or automated)equipment to produce long length mouldings and have all the defects removed.

2. Manufacturing process

1). Moulding preparation the wood blanks are maufactured in mouling profiles.

2). Surface sand following moulding preparation, Machined(produced) with high speed planing equipment To yield a premium finish timber moulding ready for priming with a gesso coating.

3). Priming-stage 1: Mouldings are spray-coated with the 1st application of thin gesso coating.

4). Intermediate sanding stage: Surface sand following priming stage 1

5). Mouldings are spray-coated with the 2st(and final) application of water base primer.

6). Final product check with light sand and buff to the surface, that is readily painted with quality topcoats

Package

1. All mouldings to be packed in mini-bundles secured with tape, within the main pack structure.

2. Packs will be then strapped securely with poly strapping (to be confirmed by customer) To secure for shipment.

3. All bottom packs are secured to a plywood pallet that allows containerisation and unloading

Quality standards

1. Moisture content must be accurately tested with an electronic moisture meter.

2. All dimensions should be within the dimensional tolerances as specified on the order

3. Coating application would be applied equally on all edges and has a strong adhesion to the wood substrate throug testing .No visible defects like patching,open finger joints, bleed through,etc,after being coated/primed

4. Mouldings would stay straight and not have excessive bow or spring.

We promise

* Your inquiry related to our products or prices will be replied in 12 hours in working date .

* Every penny you paid will be valuable.

* Compensation will be covered in next order even if there is only one pc of failed product.

Xiamen Reshine Wood Industry Co., Ltd. Was specialized in manufacture and export kinds of Door and Window materials, We have been in this business scope since 2006.

Reshine's main products range include:

1)Wood mouldings, PVC mouldings

2)Door Frames/Jambs

3)Window Shutters and Shutter components(Material: PVC/WOOD)

4)HDF door skin and HDF moulded door

Reshine's products was widely sold to: USA, Canada, Australia, THE NETHERLAND, Germany, SOUTH EAST Asia AND Middle East market.

With 10 years experience, Reshine have developed a professional management and technical team and sales team.

Reshine select our strategic partners with international quality standard. We strictly control the quality and provide QC inspection during production and before loading. Reshine always provide competitive price, best quality, quick shipment and developing new products.

For any query and problems, Reshine team will communicate with client honestly. We trust any problem can be solved if we sit down together and joint together.

Our aim is establishing long-term equal and mutual benefit business relations and develop together with each other.

Reshine's sales team and after sales team is ready to receive any of your enquiry and will reply you in time within 12 hours.

Our head office located in the special ecnomic zone: XIAMEN city, FUJIAN province.

Welcomed to visit us...