We will offer the mould assembly drawing for customer further discussion when necessary, considering about product parting line, gate, ejector position, water cooling layout, moving direction and distance of slide etc, then define a solution with which customer is the most satisfied.

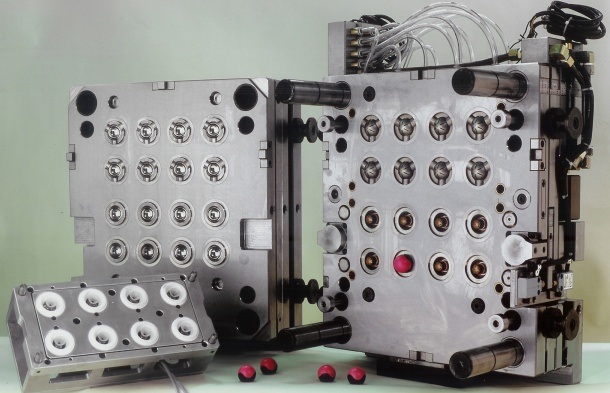

We can also design mould for customer independently, offer trial sample for customer's final confirmation, think over and get the best solution for you. Many kinds of world-wide applied mould steels are used in our production, such as 718, 738, S136 H13 from ASSAB of Sweden, NAK80 from DAIDO of Japan and P20, 420. Most mould bases and standard components come from LKM. At the same time, we can design mould according to customer's requirement, such as DME, HASCO, etc,

After the final confirmation to mould by customer, we will pack the mould with standard exporting package to avoid any damage during the long distance delivery by sea or by air. There are the trial samples, trial report and some replaceable parts provided at the same time.

Every mould components will be produced and checked strictly according to separate standard drawing. When the mould is exported, we can send the full set of mould assembly drawing and components drawing to customer for their information supplement, it is a value-added service and totally fee-free.

We also provide a full range of after-sell service to further guarantee customer's production, such as provide parts for replacement, assign engineer to help customer solve problem and get better solution.

High quality mold star with a high quality design. Our design team consists of 25 skilled designers and management staff with 20 years experience in mold design. Equipped with the latest hardware and software, we have the capabilities to ensure your great ideas are transformed into perfect products.

In order to help our internal people fully understand the project in details, the project evaluation meeting of each mold shall be held among our project engineer, designer tooling worker and technical director during the period of product analysis, mold parts list and mold assembly evaluation. Therefore, each mold designed by us can run efficiently with maintenance cost held to a minimum.

HT MOLD was founded in 1999 an experienced team of molders and mold makers to service the rapidly expanding plastics market. We specialize in making high-quality molds as class A molds. We intend to e a leading manufacturer of injection molds in industry. Well respected for technical expertise, fitst-rate quality, on-time delivery and value added services.