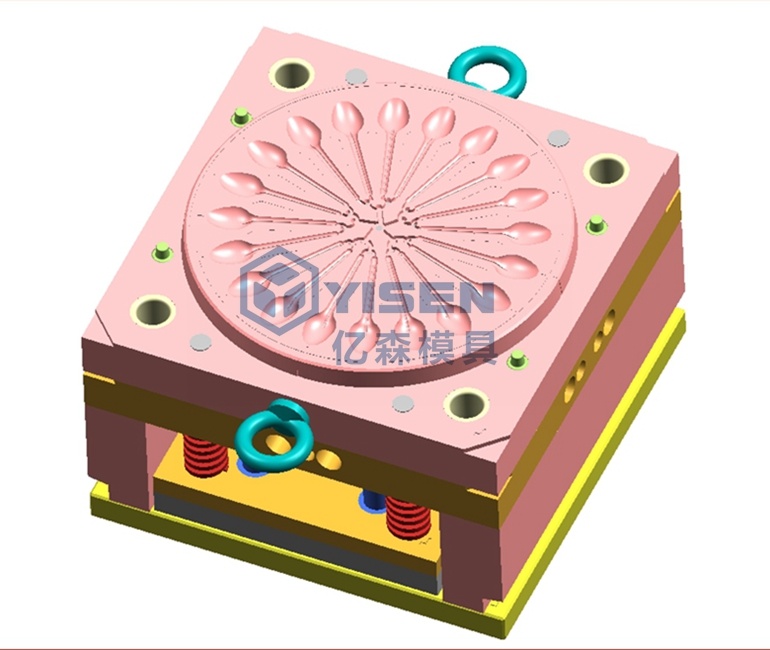

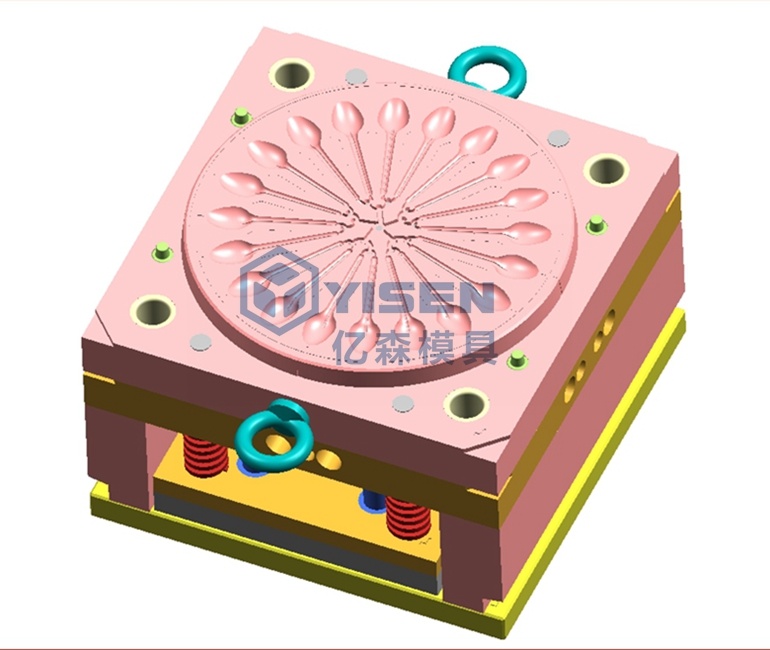

Disposable PS spoon injection moulds, we can deign the mould with 12-cavity, 18-cavity, 24-cavity...to 48-cavity.

Normally, plastic material for spoons is PS and PP, sometimes is PC.

For PS spoon moulds, the cavity & core material is S136, which is good for polishing and stainless steel with a high hardness.

We developped an technology that adding a runner switch on the mould, with this idea, we can make plastic spoons, forks and knive in the same mould, you can turn off the runner switch to choose to produce spoon or knives or forks; when you turn on the runner switch, you also can produce these 3 types products at the same time. It is a new idea that can help you save a lot investement.

Pls see this picture attached, we realize a short cycle time as 4s for our customers.

We design moulds with Good cooling system, good injection and ejection system to ensure a short cycle and a long mould life.

|

Product Name |

disposable PS plastic spoon injection moulds |

|

Product material |

PS |

|

Core& Cavity Steel |

S136 |

|

Cycle Time |

4s |

|

Mould Standard |

DME |

|

Cavity Number |

12-cavity, 18-cavity, 24-cavity... |

|

Injection System |

hot runner with runner switch |

|

Ejector System |

Ejector Pin |

|

|

|

|

Tooling lead time |

60 days |

|

Mould life |

1,000,000 times |

|

Quality assurance |

ISO9001 |

|

Our Advantage |

1. High quality |

|

2. Reasonable price |

|

3. Good Mould Design |

|

4. Strict quality control |

|

5. On time dlivery |

|

6. Good After-sale-service |