CHEMECHINA EXTRUSION TOOLING

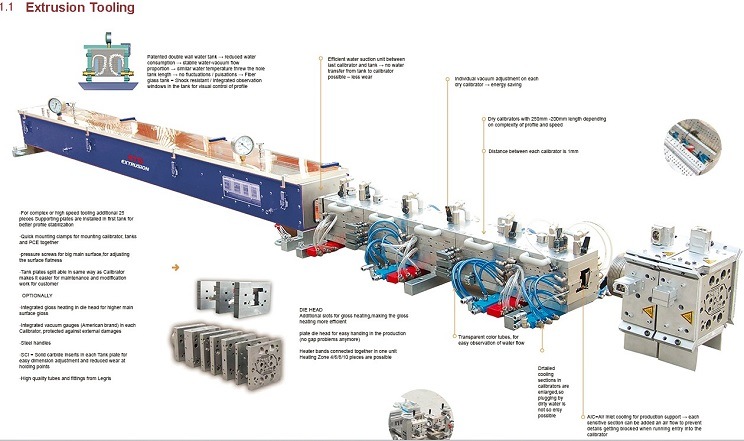

DIE HEAD

(1) Additional slots for gloss heating, making the gloss heating more efficient

(2) Plate die head for easy handling in the production(no gap problems anymore)

(3) At die exit small mandrel cap for easier handling during maintenance

(4) Heater bands connected together in one unit->Heating zones 2 / 4 / 6 / 8 /10 / 12 pieces are possible

CALIBRATOR

(1) Integrated water suction unit in last calibratork -> no water transfer from tank to calibrator possible less wear in calibrators, longer life time of tooling! !

(2) Dry calibrators with 250mm -200mm length depending on complexity of profile and speed

(3) Main surface inlet water cooling for high surface gloss and quality->water flow can be controlled by adjustment valve.

(4) 3 mounting pins for each calibrator part for precise assembly.

(5) Individual vacuum adjustment on each dry calibrator possible->energy saving

(6) Transparent color tubes, for easy observation of water flow.

(7) O-Ring free calibrator->each calibrator water hole has its own water in/out, so it is easy to check if water hole is plugged.

(8) Detailed cooling sections in calibrators are enlarged, so plugging by dirty water is not so easy possible.

(9) Calibrator 2-3 and 4-5 are connected together with special cooling bridges for water saving

(10) Aluminum free tooling.

TANK / TANK PLATES

(1) Patented double wall water tank->reduced water consumption -> stabile water-vacuum flow proportion->same water temperature threw the hole tank length no fluctuations / pulsations Fiber glass tank = Shock resistant, with integrated observation windows in the tank for visual control of profile.

(2) For complex or high speed tooling additional 15-25 pieces Supporting plates are installed in first tank for better profile stabilization

(3) Quick mounting clamps for mounting calibrator, tanks and PCE together

(4) Pressure screws for big main surface, for adjusting the surface flatness

(5) Tank plates split able in same way as Calibrator -> makes it easier for maintenance and modification work for customer

OPTIONALLY for tooling

(1) Integrated gloss heating in die head for higher main surface gloss

(2) Integrated vacuum gauges (American brand) in each Calibrator, protected against external damages

(3) Steel handles

(4) SCI = Solid carbide inserts in each Tank plate for easy dimension adjustment and reduced wear at holding points

(5) High quality tubes and fittings from Legris

(6) AIC = Air inlet cooling for production support -> each sensitive section can be added an air flow to prevent details getting blocked when running entry into the calibrator

CHEMECHINA China CHEMICAL MACHINERY INTERNATIONAL Co., Ltd. is an exclusively foreign-owned enterprise founded at Bonded Area of Dalian China in 2001, in which was joint invested by one American and three Austrians.

Since then by the consistent efforts of our elite leading team that comes from America, Austria and Germany, 100% of our wide variety rubber & plastic processing production lines and tooling have been exported to some European counties such as Germany, Austria, Russia, Danmark and Poland...., and obtained great compliments. Therefore, it substantially implements our mission: Assure the European top quality and keep the Chinese cheap price.

Now CHEMECHINA has become a strong international group company with three factories and three companies. Here is brief introduction of them as follows:

The president of Shanghai KANG LEE MACHINERY FACTORY, Mr. Lee Kang has 29 years feeding, weighting, mixing and pneumatic conveying equipments manufacturing experience. The main products are rubber and plastic auto feed production line, dry mortar production line, foamed cement production line and ceramic plate pneumatic feeding system. The considerable market share has gained both at home and abroad.

The president of Shanghai XIECHENG RUBBER & PLASTIC MACHINERY FACTORY Mr. Zhang Jicheng has 20 years sales and after-sale-service agent experience for the Krauss-Maffei Group Germany. Since the year 2002 the factory has rapidly grown up as a top manufacturer of high-end extrusion machine in China. The exporting value has reached 6 million U. S. Dollar per year.

The DALIAN EXTRUSION Technology Co., Ltd. Was founded in 2001 in Dalian China. It is owned and managed by the three leadership members who are from Austria Greiner GmbH.

All of our products, about 300 sets extrusion tooling per year, have wholly exported to the Europe countries such as Germany, Austria, Russia and Poland...., annually exported value are reached to 4 million U. S. Dollar. The ETDbrand, especially the patent of 6 m/min. High speed PVC extrusion tooling for window and doors are most prestigious in Europe.

The durable standards of tooling we made are as same as European Norm that should be used to produce one million meters profiles. Actually at some PVC profile manufacturing plants in Germany and Russia our tooling have magically produced 3 million, even 5 million meters PVC profile, but it is still using now. This is the fact of our reliable quality!

The branch company CHEMECHINA TRADING GmbH in Austria is in charge of European marketing development. Mr. Lothsa Hans and his elite sales team have wide sales nets in Europe. They made very great contribution every year more then a decade.

The branch company CHEMECHINA ENGINEERING GmbH in Germany is in charge of field installation and tuning works as well as after-sales-service. The engineer Mr. Luca Finn and his team have exquisite skill, rigorous and precise working attitude. More then a decade they ensure all of production lines and tooling we exported to the Europe in a normal operating condition and gained consistent high praise from our clients of the Europe countries.

With the equipments, staff and capacity growing up, not only the European market but also the Global Marketing strategy has put into the top agenda. We organized a fine marketing team to expand towards North & South American, Asia, Africa and Australia markets. We warmly invite worldwide companies or individual to join us as a salse and after-sales-service agent in your country. Let the world understand CHEMECHINA and share our top quality but cheap price products, meanwhile, we firmly believe the CHEMECHINA will gain a global reputation in the near future.