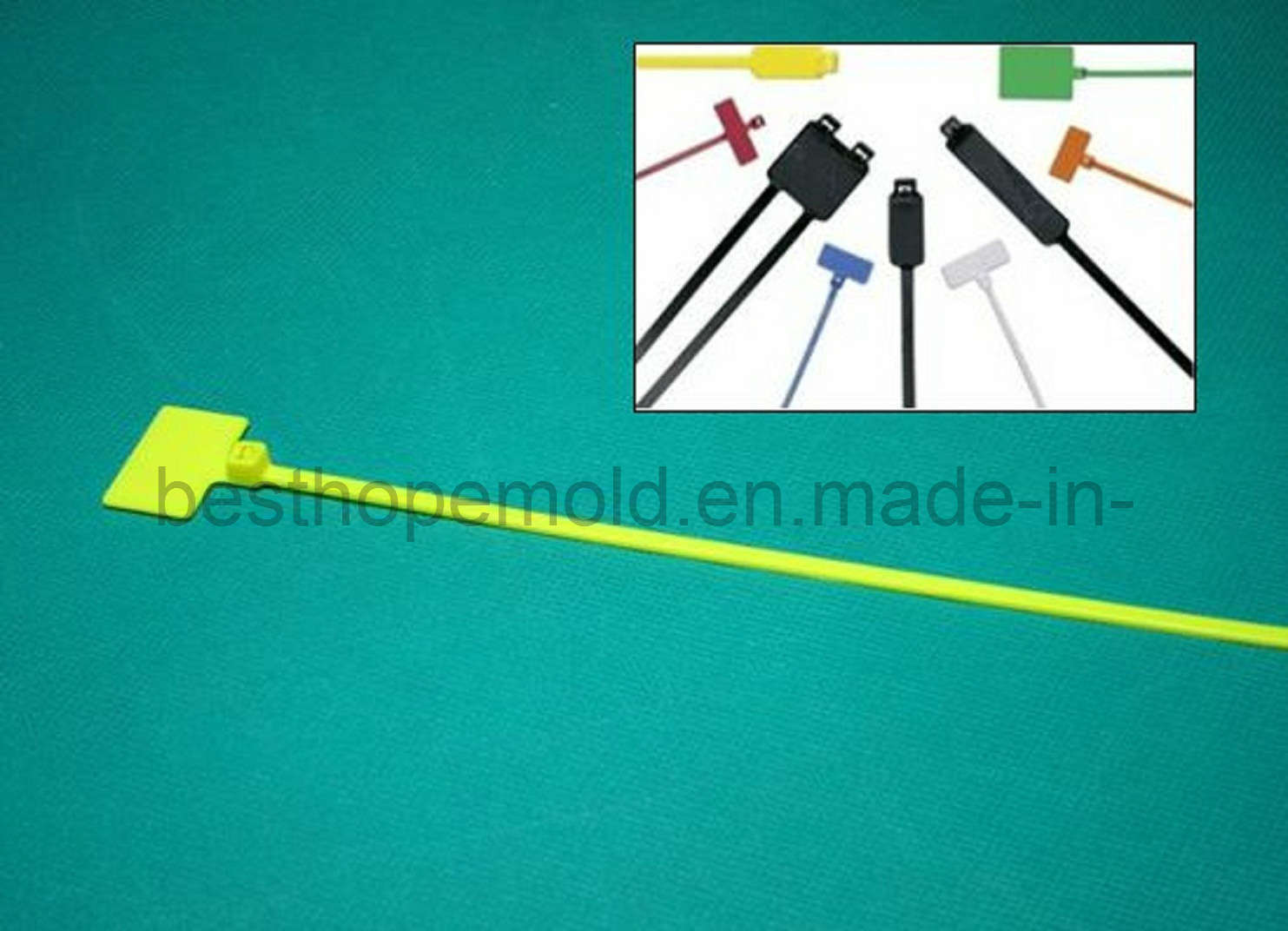

Flag Cable Ties Plastic Injection Mould (BHM-TM02)

Our company have obtained ISO9001: 2008 quality management certification.

And both our molds and products meet the standard of Europe and America.

Identification of Cable Ties

Tie and identify bundles of cable in one operation. Large flat area for imprinting or writing the required information. Hot stamping available!

Specifications:

Color: Natural (White and standard colour), UV Black and other colours are available

Weight: 1.25/1.28g

Material: Nylon66/ UL94-V2; Resistant to heat, acid and erosion.

Type: Self-locking

Tension: 18kg-25kg

Packing: 100PCS/polybag 200bags/carton (54*35*32cm); Other packing available as per customer's requirements

Lead time: Parts 20-25 days; Moulds: 30-35 days

Part Payment Terms: 50% as down payment; 50% before shipment

Tooling payment: TT 50% as advance payment when confirm order by both side, balance to be wired when tools finished and before shipment.

Other items: Mountable cable ties, Double locking cable ties, Knot cable ties and so on

If have any question please contact us freely.

Features:

1. Moulds for AS, PC, PP, ABS, POM, PE, and other plastic material.

2. Imported steel from Sewden, Germany for cavityand core pin, with very good shining or matte surface on customer-s requirement.

3. Moulds type: Split mould and integrated mould; Hot runner mould and cold runner mould;

4. Mould cavity no.: According to customer's requirements and plastic parts structure. We can make 8, 12, 14, 16, 18, 20, 24.32, 36, 40, 48, 64 and more,

5. Mould life: We can make moulds life different according to customer's production capacity, by using different mould steel. The maximum mould life is 3 million shots.

6. Other features: Good steel, short delivery time, and low cost, will bring you much competitiveness.

We are looking forward to your inquiry!

Brief work procedures | 1. We can do based on your 2D/3D drawings or original samples

2. We have 23 engineers responsible for parts design and tooling, drawings can be sent to you with 2-3 days.

3. When advance payment received and drawings confirm, we start molds tooling

4. Normally 35 days later, we do mold test, check samples and improve molds

5. T1 mold test samples will be sent to customer

6. Customer confirm samples, if prepare molds shipment or do mass production of plastic parts |

| What we can guarantee | 1. Competitive labor cost will bring you whole project cost down.

2. High precision tooling and fresh material using can meet the same quality level as Europe and USA.

3. Our high efficiency will be good assistance for your finish products and launch to market earlier than others! For custom making products, Confidential Agreement is always we will comply with.

|

Best Hope Mold & Plastic (Shanghai) Co., Ltd (BHM) focus on high precision Plastic Injection Molds design and developing, as well as custom injection molding.

BHM' S Facilities:

BHM owns two facilities located in Shanghai and Suzhou, respectively focuses on high precision molds and large size molds.

Since established in 2005, BHM has been developing very fast, business expands rapidly due to quality products and serves, At present, BHM has covers an area of 10000m2 in total and owns 185 employees including 28 engineers, 110molds makers, 10 QC personnel and many injection operators.

BHM' S Capabilities:

BHM offer one-stop services from engineering design, tooling, to custom injection molding, as well as printing and assembly etc.

Design for manufacturability and efficient production is our primary objective. The mold drawings can be finished within 2-4 days then send to customer for checking before tooling. We are able to meet our customers' Shortened lead time. All the necessary technical drawings will be sent to customers for future mold maintenance references.

Our high speed milling machine, EDM, WEDM and CMM optimize our tooling process and improve accuracy and efficiency of our mold to ensure customers can get quality product.

Our expertise in tooling leads to better results in molding. We have 11 injection machines for mold trial, mold validation and custom production.

We have enough experience working with materials such as: LDPE, HDPE, PP, ABS, PC, PS, PVC, PA, PMMA, POM, TPU, TPR, TPE etc.