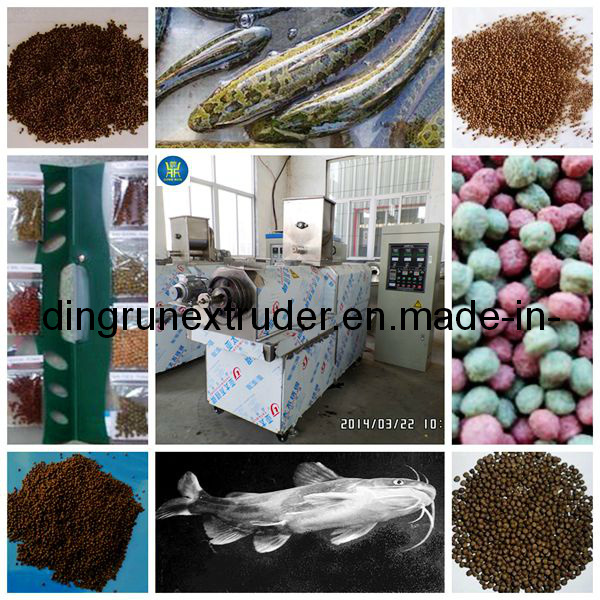

Floating fish feed machine

About our company

We follow the ideals of "customer oriented, common development". Jiaozuo hengmu has a group of talents who have rich experience and high quality. We can design, develop and produce different kinds of machines according to the needs of customers.

I. Introduction for Floating Fish Feed Pellet Machine

It is widely used for producing maize flour, soybean flour or compound powder, wheat bran into high grade aquatic feed pellets for fish, catfish, shrimps, dog, . Cat etc. The puffing fish feed pellets can float on the water surface for over12 hours without water polution. According to your requirement and production scale, floating fish feed machine can be classified into dry type machine and wet type machine.

II. Working principle for Floating Fish Feed Pellet Machine:

After the material is sent into feeding device, they will be extruded and expanded by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized. Then the expanded material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters. After that a cutting device will cut the formed pellets into different length as required.

III. Features for Floating Fish Feed Pellet Machine:

1. According to different requirements, variety shapes of high-grade feed pellets for fish, shrimps. etc

2. The finished pellets can keep floating for 12 hours without pollution to water.

3. The floating time can be controlled by the puffing degree adjustment

4. Floating fish feed machine can make pellet from diameter 1mm-12mm just by changing the mould.

5. Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6. High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and

Also makes the pellets easily to digest.

7. The cutting device can be adjusted to make pellets of different length.

8. The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

IV. Complete flow chart for Floating Fish Feed Pellet Machine:

Raw material preprocessing--crushing--mixing--extruder--cooler--dryer--flavoring

| Model | Installed powder | Real powder | output |

| DSE65 | 70kw | 40kw | 100-150kg/h |

| DSE70 | 100kw | 70kw | 200-260kg/h |

| DSE85 | 200kw | 150kw | 500-600kg/h

|

Jinan Dingrun Machinery Co., Ltd is a professional food machinery manufacturer in Jinan city shandong province China.

Our company congregates an exceptional food machine engineering team, personal customer service center and high quality manufacturing capabilities have evolved exponentially, We are working hard on explore constantly not only in the research of extrusion technology, but also in food technics to benefit our clients producing newfangled food in their markets. It making us become one of the preeminent providers of reliable extrusion equipment world-wide. Now we can guarantee customers superior quality machines up to design requirements and perfect working state.

With our many years research and development extrusion technics has been widely used in more fields. Our products consist of core filling extrusion snack machine, corn chips machine, bugles machine, twin screw food extruder, breakfast cereal and corn flakes machine, pet food machines and floating fish feed machinery, dog chewing food machine, aquarium fish feed machines, textured soya protein machine, modified starch machine, artificial rice machine, bread crumb machine, single screw extruder, potato chips machine and biscuits machine, instant flour machine, flat bread machine, ect. We can also provide special design and product according to our clients` special requirements.

Now, we have exported our machines to many countries in the world, such as Malaysia, Indonesia. Pakistan, Sri Lanka, Brazil etc., and get good reputation from the clients. Some of them become our agents in their area. We hope to have long friendly business relationship with more clients all over the wrld in the future.