Specifications

Fish feed machine

1.High quality

2 Reasonable price

3 easy to install and easy to operate

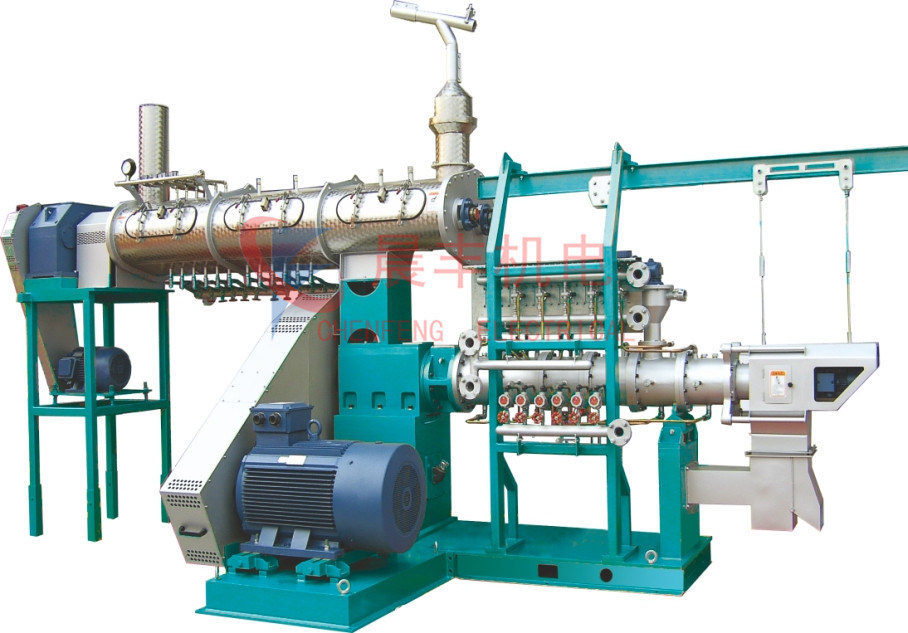

Floating fish feed pellet machine

Floating fish feed pellet machine ------- Introduction :

Floating pellet machine is widely used for producing grains into high-grade aquatic feed pellets for fish, catfish, shrimps, crab etc.

The puffing fish feed pellets can float on the water surface without dissolution for over 12 hours.

According to your requirement and production scale, floating fish feed machine can be classified into dry type machine and wet type machine.

Floating fish feed pellet machine -------- Working principle :

After the material is sent into feeding device, they will be pressed by the screw shaft with high pressure and temperature which makes the raw material fully cooked and sterilized.

Then the pressed material will be formed into pellets by shaping mould. You can change different moulds to make pellets with different diameters.

After that a cutting device will cut the formed pellets into different length as required.

Floating fish feed pellet machine -------- Application and features :

1.According to different requirements, variety shapes of high-grade feed pellets for fish, shrimps .etc can be produced.

2.The finished pellets can keep floating for 3-15 hours without pollution to water.

3.The floating time can be controlled by the puffing degree adjustment.

4.Floating fish feed pellt mill machine can make pellet from dia.1.0mm-20mm just by changing the mold.

5.Electric heating device is adopted which can improve the feed expansion rate and pellets floating time.

6.High temperature and high pressure cooking process can kill the salmonellosis and bacterial infections and also makes the pellets easily to digest.

7.The cutting device can be adjusted to make pellets of different length.

8.The wet type machine needs a boiler to make steam which can conduct steam to the conditioner and ripen the raw material in advance.

Floating fish feed pellet machine -------- Raw materials :

raw materials can be: corn,wheat,soybean,grain ,bone powder etc

raw materials need grind into 60-80mesh

raw materials moisture content : 20-25%

Fish floating feed pellet machine -------- Advantge :

1) With different moulds, the machine can produce different diameter food, from 0.9mm to 10 mm.

The food can meet different stage fish. The food can be floating 24hours.

2 ) It can produce different shapes feed for fish, dog, cat etc.

Through the pretreatment of the feed, it can reduce loss of nutrition and advance the protein ratio.

So the feed will be digested easily by animals.

Model | Main Power

(kw) | Feeder Power

(kw) | Conditioner Power

(kw) | Cutter Power

(kw) | Capacity

(t/h) |

| SPHS95S | 55 | 1.5 | 5.5 | 3 | 0.5~1.2 |

| SPHS98S | 75 | 1.5 | 5.5 | 3 | 0.6~1.6 |

| SPHS118S | 90 | 1.5 | 11 | 4 | 0.8~2.0 |

| SPHS120S | 110 | 1.5 | 11 | 4 | 1.5~2.2 |

| SPHS145S | 132 | 1.5 | 15 | 5.5 | 2.0~4.0 |

| SPHS148S | 160~200 | 1.5 | 15 | 5.5 | 3.0~6.0 |

| SPHS150S | 200~315 | 2.2 | 18.5 | 5.5 | 8.0~10 |

Professional Design: We are leading manufacturer in China, we have professional design team, we specialize in feed processing machinery, food processing machinery and biomass energy pelleting equipments. The technology flow is followed the trend of latest industry development and the best plan is designed according to customer's requirements and local conditions. The general layout is reasonable, economical with detailed consideration from customer side.

Professional Manufacture: All machines are stable, safety, reliable; The plant is with high automation level, reducing the labor intensity of workers; The automatic control for process of production through advanced centralized control system guarantees lowest operational cost.

Professional Installation: We have professional installation team with skillful experience for many years. They are careful and responsible.

Environment Friendly: Dust, noise and drainage of waste water meet environmental requirements.

Turn-Key Projects And Machines

Livestock & Poultry Feed Project

Chicken Feed Project

Swine Feed Project

Cattle, Sheep& Horse Feed Project

Mouse& Bird Feed Project

Aqua Feed Project

Fish Feed Project

Shrimp Feed Project

Special Aqua Feed Project

Concentrate Feed Project

Premix Feed Project

Porket Feed Project

Straw Feed Project

Pasture Feed Project

Wood Pellet Project

Spice Processing Project

Herbaceous Plant Processing Project

Hops Pelleting Project

Chrysanthemum Pelleting Project

Biological Fertilizer, Organic Fertilizer,

Compound Fertilizer Project

Steel Structure Production Building Project

Steel Structure Silo project

Material Storage, Drying project

The turnkey project service

1. The general layout design of the plant

2. The electrical design of the powder, pellet workshop

3. The main design of the pellet workshop

4. The main workshop of all machinery and equipment (including frame, wind pipe, feeding pipe, bin, compressed air system and other non-standard parts) production, installation and commissioning

5. Design and installation, commissioning of all electrical control system

6. On-site training operation repair personnel

7. Long-term supply of spare parts

8. Long-term provision of technical information and business consulting.