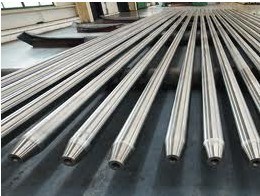

Retained Mandrel Bars:

The retained mandrel bars for the production of large-sized seamless steel pipe is used in sectional structure. Its working section is exposed to complex and huge surface pressure as well as thermal cold-hot fatigue, whereas its connection part has to withstand mechanical forces during the pressing process.

The working part of the retained mandrel bars produced by Besco adopts H13 hot-work die steel. The production processes, that include smelting, forging, rough machining, heat treatment, semi-finished & finished machining, chrome plating and phosphate treatment, ensures the following characteristics.

Besco is upgrading the mandrel material bars and its manufacturing technology in close collaboration with.

Material: H13 & 42CrMo

Diameter: 80-450mm

Length: 2500-17500mm

The Retained Mandrel Bar is one of the key instruments to manufacture seamless steel tubes. Our company is capable of producing a series of mandrel, such as MPM, PQF, FQM, with the diameter ofΦ80-450mm, the length of 2500-17500mm, as a result of making the best use of our advantage in steel making, forging, heat treatment, machining plating chromium adequately. The raw steel material is AISI H13 or 4CrMoSiV1, based on enterprise specifications.

Besco Steel Works Limited covers an area of 18000 square meters, We have forging, mill roll, large machining, heat treatment four branch factory and variety of heat treatment equipment: Heating furnace; Annealing furnace; Induction quenching equipment; Deep cold equipment, vibration aging machine etc. With capacity of long 16000mm; Diameter Φ 1450mm; Weight 15000KG; And can reach the hardness hrs 102. Modern heat treatment furnaces enabling precise control of mechanical and physical properties. Our company have more than 300 staff, senior technical personnel more than 50 people among them. The company has a central laboratory, for all kinds of materials, the chemical composition of the microstructure, physical properties of testing and analysis, to ensure the quality of products.