Home Mould Products Gooseneck Punch / Bottom Tooling / Bottom Moulds / Upper Tooling / Square Die / Square Multi-V Moulds for Press Brake

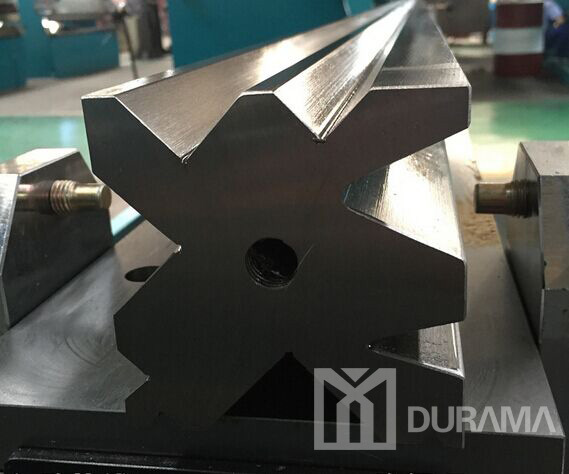

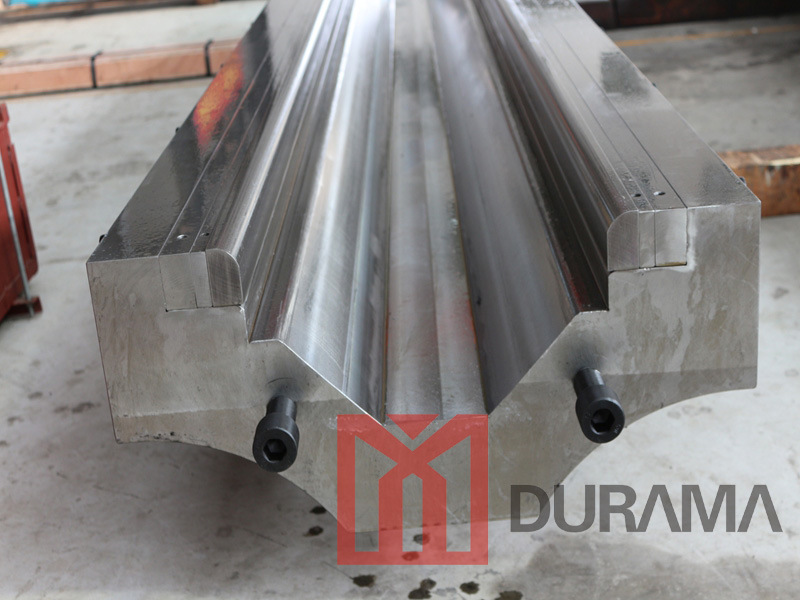

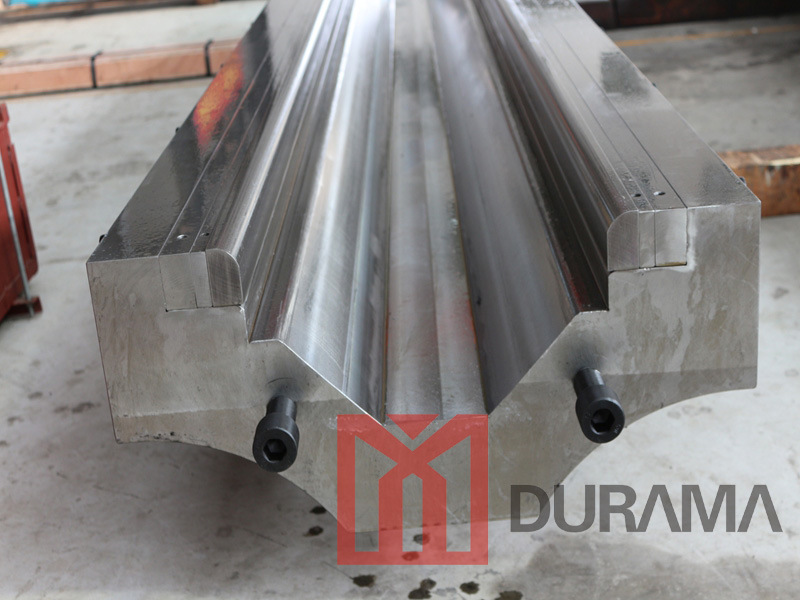

Gooseneck Punch / Bottom Tooling / Bottom Moulds / Upper Tooling / Square Die / Square Multi-V Moulds for Press Brake

| Price: |

US $ 500-2000/Set |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,Western Union |

DURAMA PRODUCT DESCRIPTION:

DURAMA top punches;

DURAMA tools, gooseneck tool for press brake;

DURAMA square dies for bending machine;

Wila tools for press brake.

Plano dado de plegadoras o dobladoras.

Press Brake Dies & Punches.

Dies for press brake.

Toolings for press brake.

Matrix for press brake.

Moulds for press brake.

Moulding for press brake.

Material : 42CrMo

Hardness : HRC 50~55

Delivery Time : Within 20 days

ISO 9001-2000 Certification

| Material | 42CrMo | HRC50~55 |

|

|

| T8/T10 | HB280~320 |

|

|

|

|

|

|

|

Material And Hardness:

1) Material : 42CrMo HRC50~55

2) Material : T7/T8, HB 280-320

Technical requirements:

1. Angle of all V-type grooves is 88°+10′ , and the R of groove bottom is 0.5.

2. R of the chamfer angle of V-type grooves is 0.5, which should be kept the same on the whole length.

3. The other chamfer angles are 1×45°.

4. Heat treatment HB 220-250.

We can design special tools for you.

We can also supply following types toolings:

1) Euro. Style

2) China GB Standard Style

3) Trumpf-Wila Style

4) LVD Style

5) American Style

6) Amada Promecam & Amada Quick Set Style, etc

| Prod Model: |

DRB |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Raw Material: |

T8, T10, 42CrMo etc |

| Application: |

Commodity |

| Material: |

High Carbon High Chromium Tool Steel |

| Processing Method: |

Punching and Shearing Mould |

| Technics: |

Bending Die |

| Process Combination: |

Progressive Die |

| Manufacturing Technology: |

Computer Technology |

| Driving Motor Type: |

Permanent Magnet |

| Mold Cavity Technology: |

The Traditional Forming Electrode Machining |

| Milling Speed: |

Normal Speed |

| Parts Detection Method: |

Geometric Detection |

Welcome to DURAMA!

We are DURAMA, durable machines and spare parts supplier, the designers and manufacturers of industry products. Our factories are located in industrial area in Nanjing City. With over 10 years of experience, DURAMA supplies the most comprehensive range of machines and spare parts available today.

We supply Press Brake Tools for most famous Press Brake in the world, including Amada, Beyeler, Colly, Durma, LVD, Trumpf, Wila, etc. All our products are available for immediate dispatch, enabling you to tackle any project with confidence. We supply Shearing Machine Blades for most models.

We supply many popular machines such as hydraulic iron worker, hydraulic notcher, mechanical power press, mechanical shears, and mechanical rolling machines etc...

With continued investment and an unrivaled reputation for quality and service, DURAMA is trying to be the global center of excellence for Press Brake Tools and bending technology. We also supply relative industry machines and materials.

DURAMA is always trying best to supply durable machines and spare parts, and timeproof service to our customers.

DURAMA is always trying best to supply durable machines and spare parts, and timeproof service to our customers.