| Markets: |

North America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Application: |

Household Appliances |

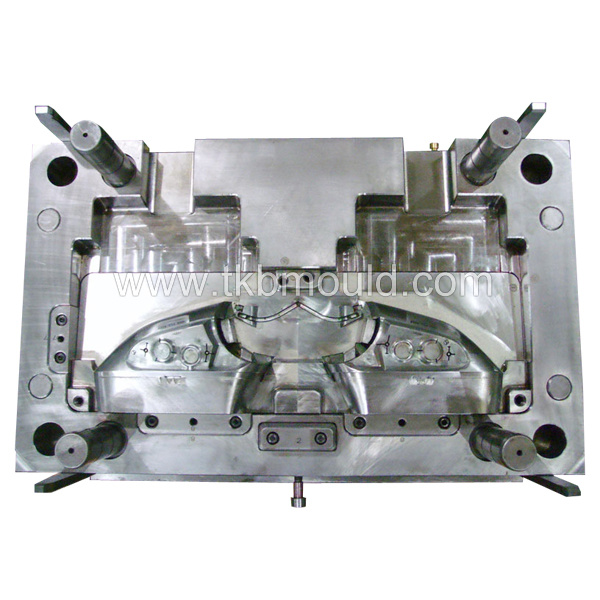

Product Description

Plastic Mold for fashion bottle

Excellent Quality

Competitive Price

On-Time Delivery

Certification: ISO9001: 2008

1) Provide 3D design

2) CNC&EDM machining

3) OEM service

4) LKM Mould Base

5) Mould Life: 500, 000 Shots

5) ISO certificated mould maker

6) Delivery Time: 30~40 days

7) Transportation: By sea or By air

8) Material of the mould: As your requirement

9) Rich experience on developing moulds and producing plastic products

1. OEM/ODM parts range: Auto parts, computers, communications systems, cell phones, digital camera and home appliance etc.

2. Available materials: All kinds of Plastic material, such as PS, ABS, HIPS, PP, PVC, PMMA, PBT, PC, RUBBER, SILICON RUBBER, etc

3. Available production processes: CAD/CAM. PRO-E, Cimatron services, expert plastic injection, metal processing, finish, heat treatment, surface plating.

4. Drawing Format: Drawings and files in the formats of *. IGS or *. STP, DWG, DXF are welcomed. We use PRO/E and Solidworks to analyze and draw 3D files.

5. Advanced inspection equipments for rigorous quality and control and precise specification

6. Comprehensive engineering and manufacturing services for Plastic Mold: R&D process, product design, test.

7. Quote Price Time: After we receive your drawings, we will quote you the pricing for both mold and product 1 Work day.

8. For UL, VDE AND RoHS compliant, the reports will be provided by SGS as per customer's requirement.

9. Good communication with customer through the whole production.

We are professional designer and manufacturer of injection molds for several years, covering plastic and metal part for engineering accessories and equipments, automotive, family appliance, computer, toy and telecommunication device, etc.

Certification ISO9001: 2008

Mould material P20, 45#, 60#, 718, 2316^...

Shaping mold Plastic injection mould

Mould cavity Single/Multi

Mould base LKM

Runner system cold runner, hot runner

Mould life 300, 000, 100, 000, 500, 000^^

Processing equipment CNC machine center, OMAG, EDM, ^^etc

Delivery detail 15-60days

Payment terms T/T

Packaging Detail Wooden case package or according to customer needs

Remark

Think Bus Kalung (HK) manufacturing Ltd., is an ISO 9001 certified management system factory located in Guangdong Doungguan City, China.

A privately owned company specializing in manufacturing high-quality injection moulds, plastic injected products for international markets. The factory is equipped with CNC, EDM machines to produce high precision products, as well as injection machines of 600 tons, We also specialise in providing: Cutting, tinning, wire stripping, twisting; Terminal connector insertions and wire assembly processes.

All of our operations adhere to ISO 9001 and ISO 14001 guidelines. Each item undergoes strict quality control inspections and testing - from raw materials to finished products. Before production, samples are provided to you for approval. We also offer packing services and shipment arrangements. We assure you of cost-effective solutions to your marketing objectives. E-mail us to find out how we can fill your requirements. We sincerely hope we can become your mold supplier of choice in China.

Think Bus Kalung (HK) manufacturing Ltd., is an ISO 9001 certified management system factory located in Guangdong Doungguan City, China.

A privately owned company specializing in manufacturing high-quality injection moulds, plastic injected products for international markets. The factory is equipped with CNC, EDM machines to produce high precision products, as well as injection machines of 600 tons, We also specialise in providing: Cutting, tinning, wire stripping, twisting; Terminal connector insertions and wire assembly processes.

All of our operations adhere to ISO 9001 and ISO 14001 guidelines. Each item undergoes strict quality control inspections and testing - from raw materials to finished products. Before production, samples are provided to you for approval. We also offer packing services and shipment arrangements. We assure you of cost-effective solutions to your marketing objectives. E-mail us to find out how we can fill your requirements. We sincerely hope we can become your mold supplier of choice in China.