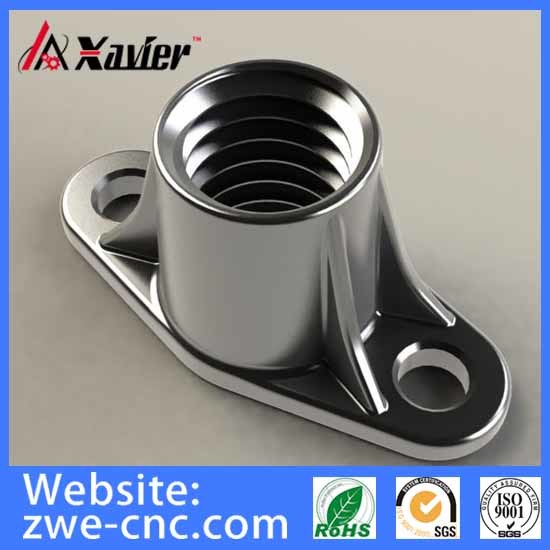

high precision metal injection moulding part ,aircraft part

We professionally manufacture high precision metal injection moulding parts. Sincerely hope that we can assist your business with our rich engineering expertise and premium customer service.

Company introduction:

Main services and products:

custom cnc machining, cnc turning, cnc milling, forging,forged aluminum, cold forging, hot forging,

metal casting,die casting, investment casting, sand casting, gravity die

casting,centrifugal casting, titanium machining, titanium investment

casting; metal injection moulding;

gun scope parts, bipod & tripod parts, AR-15 parts, night-vision device parts, FSA bike parts, helicopter power system parts, spur gears, transmission gear, worm gear, camshaft, ring gear, plastic gears, custom carbon fiber hoods, carbon fiber kits.

Scope of business :( military, aerospace, automotive, medical, communications, machinery) hardware parts, assemblies, kits OEM \ ODM services; new composite molding scheme design and manufacturing; gear, hydraulic, power transmission system and related parts manufacturing.

| Business Type | Manufacturer (Custom CNC Machining Services) |

Materials

Available | SS201, SS303, SS304, SS316 etc. Steel: Q235, 20#, 45# etc. Brass: C36000 (C26800), C37700 (HPb59), C38500( HPb58)tC27200(CuZn37), C28000(CuZn4)

Iron: 1213, 12L14, 1215, etc. Bronze: C51000, C52100, C54400, etc. Aluminum: AI6061, AI6063, AL7075, AL5052, etc. Titanium, Carbon fiber.

Plastic: ABS, PC, PE, POW, Nylon, Teflon, PP. etc./as per you required. |

| Processing | CNC milling and turning, grinding, bending, stamping,casting, forging,etc. |

| Surface Treatment | Zinc-plated, nickel plated,chrome-plated, silver-plated, gold-plated,anodizing etc. |

| Tolerance | ± 0.005mm |

| Surface Roughness | Ra0.8-3.2 |

| DRW Format | PDF/ DWG/ IGS/ IGES/STEP/ STP,etc. |

| Equipment | CNC lathe, CNC machining center, CNC milling machines, etc. |

| Capacity | 50, OOOpieces per month |

| MOQ | 20pcs |

| QC System | 100% inspection before shipment |

| Payment Term | T/T, Pay Pal, West Union |

| Trade Terms | FOB, CIF, as per customers request |

| Shipment Terms | 1) 0-100kg: air freight priority 2) > 100kg: sea freight priority

3)As per customized specifications |

| Packaging Method | 1.Neutral packing (neutral plastic bag+ neutral carton)

2.Custom packing ( with logo or barcode according to your requirement) |

| Delivery Time | 25-45 days |

| Note | Any machining need,just send drawings to us. We are ready to assist your business. |

Our enterprise core value is integrity and quality. We have been cooperating happily with our customers and earned good reputation with our superior product quality and premium service.

Sincerely hope that we can assist your business.

Any machining need , just contact me.

Thank you!

Xavier Precision Co., Ltd. is located in Shenzhen, China. Over this years mainly to provide military industry, aerospace OEM metal parts for AVIC, 713 Institute, 628 Institute, 132 manufacturer and so on. During Cooperation we get much more produce experience, and research many new parts, improve our technology, especially in the special materials, new materials, aerospace aluminum and so on.

In 2013 years Xavier registered in Hong Kong and began to explore the international market. Mainly Provide metal cutting, sheet metal / welding, casting, forging, stamping and other services, for the global military, aerospace, automotive, medical, machinery, design and production of precision components, complex non-standard parts.

2014 Xavier signed an cooperation agreement with Germany and Belgium 2 design company. Whose Designers both have more than 15 years of professional experience. Mainly supply design structure, cost analysis, assembly and testing, technical support and after-sales service for European and North-American customer, To build a low-cost, high-quality system, achieve win and win.

On the produce processing, Xavier have very experienced technology engineer whose more than 25 years experience in military factories mechanical for product analysis process. Combined with ISO9001 quality management system:

Each part base on the material, quantity, performance parameters

Required to improve the production process;

Each production process strictly according the SOP document;

Writing CAM toolpath automatically performed every cutting process;

Each CNC machines are equipped with an automatic tool changer system;

Each batch of products are own inspection reports, any problem can be traced back production, equipment, IPQC, FQC and all other relevant details, Achieve improvement and upgrading speed and accurate for service and quality.

Simulation processing --equipment testing → First processing inspection → → Recording the machining size rules → Recording the cutter compensation rules → Recording cutter life-Recording random inspection---check the standard of processing --Finished products.

The whole processing which can avoding the unsteady -tolerance, scratches and other defects caseued by

Worker touch this parts.

Use High-precision Tech!

Building world-wide brand!

High, precison, accurate is Xaviers key values,

CNC machining one-stop service is Xaviers aim.

Customer satisfy is Xavier pursuit!