--- Description

1. Made of SGCC by continuous stamping and bending,

2. Has accurate size, the highest precision up to +/-0.05mm,

ensuring effectively assembling with other parts,

3. High producing efficiency and low cost, shorten the production cycle.

4. Material surface with hot dip galvanizing layer,

without the coating or plating finish,still good at anticorrosion and rustproof.

5. Suitable for various auto parts, household appliances, office equipment

(such as printers, copiers), construction, production machinery, and other fields.

6. Specialized in varieties of bracket, metal connector, stamping metal part,

laser cutting , CNC milling , CNC turning, and so on.

--- Service| Country of Origin | Dongguan, Guandong, China |

| Materials | 1. Steel: C45(K1045), C46(K1046), C20, Cold roll steel, Q235 , mild steel , Carbon steel

2. Stainless steel : SUS201, SUS303, SUS304, SUS316, SUS410, SUS420,

1.4301, 1.4305, AISI201, AISI303, AISI304, AISI316, AISI410, AISI420.

3. Brass:C36000 ( C26800/H65), C37700 ( HPb59), C38500( HPb58)

4. Iron: 1213, 12L14,1215,ect

5. Alloy steel: SCM435,10B21

6. Aluminum: Al6061, Al6063, Al5052, Al7075, etc |

| Max Machined size | Laser cutting : L 2000mm * W : 4000mm

Stamping : Length: 500mm; width: 500mm

CNC machine: L : 500mm : Width: 300mm |

| Drawings | DWG, SLD, STP, PRT. IGS, PDF, JPEG etc. |

Surface treatment

/Finished | Oxidized, Brushed, painting, powder coating, electrophoresis, zinc plated,

nickel plated, polishing, passivated, Ti-plated, Chrome plated , Electro plating , Plain, |

| Mold Method | High-speed punching press , progressive die/mold, single die/mold, precision mold/die |

| Production process | EDM, mold making , stamping , deep drawing ,cutting , punching , burring ,

threading, polishing, welding, etc |

| OEM and ODM | Accepted |

| Lead time | 7~10days for prototype, 7-20 days for mass production,

confirmed according to your drawing |

| Package | PE bags, cartons, pallets, customized |

| Transport | Express-EMS, DHL, UPS, FedEx, etc.

Sea Shipping, air transport |

| Trade | EXW, FOB, CIF, C&F, D/D, DNP |

| Payment | T/T, PayPal, western union, via Escrow, L/C D/A D/P , Money Gram |

|

|

--- Features of stamping process 1. High usage of material

2. Can machine small thickness and complex shape parts

3. Stamping have good interchangeability of shape and dimension

4. Can reach the parts which have light weight, high strength, good rigidity

5. High productivity, easy operation, easy to realize the mechanization automation.

6. The cost of Stamping mold/tooling /die is high, so it is suited to mass production

For small quantity or variety , often use simple stamping mold or laser cutting

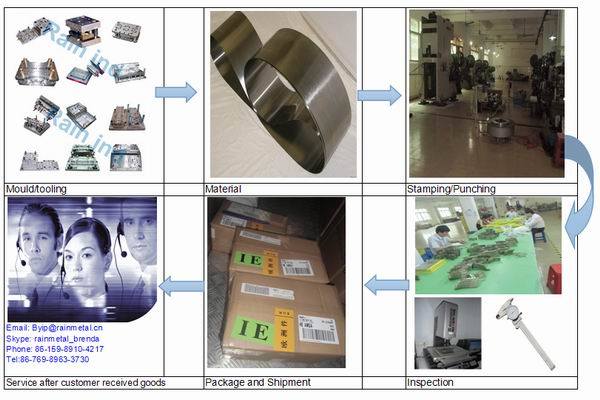

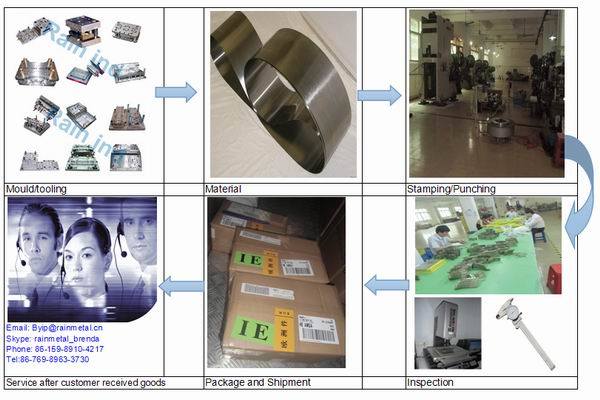

--- Simple production shedule

1. Mold making after confirmed the price

2. Samples confirm

3. Deposite arranged before mass material arranged

4. Arrange material and production

5. Inspection before surface treatment

6. Arrange surface treatment

7. Final inspection for finished parts

8. Arrange package

9. Balance cost before shipment

10. shipment

11. sales service

Dongguan Shipai Qiwei Hardware and mold factory which was established in 2007, is one passed ISO9001: 2008 international quality system certification, specializes in metal stamping, die, CNC lathes, springs, laser cutting bending manufacturing enterprises. Qiwei is Located in Dongguan Precision metal manufacturing city, close to 120 provincial highway, with convenient transportation and superior environment. �

To expand our overseas markets, we registered Dongguan Rain Industry Co., Ltd and Hong Kong Nature I&T Co., Limited on 2011. After three years growing, we have developed over one hundred customers, included Europe and America, the Middle East, Southeast Asia, Australia, South America, East Africa, Russian Federation etc. �

Our factory is one service-oriented manufacturer which have Comprehensive capabilities, included product development, design, manufacture and service as a whole. Specializing in products of electronic, electrical appliances, machinery, toys, watches, and other precision metal parts. We have full sets production equipments to meet the requirements of large or small metal parts manufacturing, promise to supply High quality, punctual delivery, and professional service for quality to you. �

We keep the management principle of "High-quality, people-oriented, customer first, excellence, reasonable price, punctual delivery". Welcome you to visit our factory for guiding work, let us join hands in creating a better future!