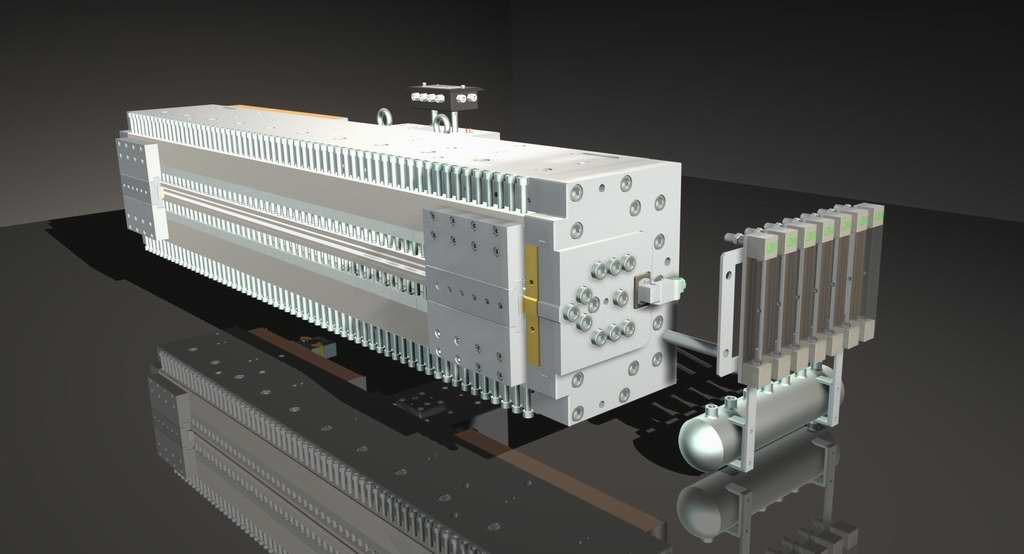

Hollow Cross Section Plate Die

| Price: |

Negotiable |

| Trade Terms: |

FOB |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,D/P |

PC hollow plate used widely in construction and decorations. The hollow gride plate die and sunblock can make UV protection on both side. The finalproduction with a MAX width of 2100mm and have a high impact strengh, good weather resistance and UV protection.

with adjustable upper and lower lips, production thickness ralative errors can be controlled within 3; Built-in heater features provides fast heating and superior tenperature retainment. The individual air volume of each section even easy to control to increase the product quality. The smoothnes of the chaannl reaches 0.015-0.03um, which ensures the stagnation-proof.

Different design can meet the different requirements of products, general polycarbonate hollow plate whose thickness is between 4-25mm, multi-layers plate such as H-cross section, X-crose section etc. The thickness of some can reach 36mm, and the UV layer can be coated.

The PP, PE hollow grid plate produced by special dies light weighted, damproof and have a high impact strengh, which is widely used as advertising light panel, exhibition upholster, carry box etc, the thickness-range is 2-12mmand thewidth is 1200-2200mm.

The cooling vacuume calibrator is manufacture from specially treated material assuring maximum wear resistance and deformation-free. Special temperature controlled water way and vacuum calibration design allow temperature adjustment to meet various physical property requirements for different materials.

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Shaping Mode: |

Forming and Forging Mould |

| Product Material: |

High Grade Alloy |

| Product: |

Plastic Products |

Shanghai Jwell Machinery Co., Ltd is the vice president unit of China Plastic Machine Industry Association, also one of the leading plastic machinery and chemical fiber equipment manufacturer in China. Our company is located in the western suburbs of Shanghai, covers an area of 300 hectares and has more than 3200 employees.

The subsidiaries of company are as following: Shanghai Jwell Extrusion Machinery Co., Ltd.; Shanghai Jwell Pipe Equipment Co., Ltd.; Shanghai Jwell Plate & Sheet Equipment Co., Ltd.; Shanghai Jwell Chemical Fiber Machinery Co., Ltd.; Shanghai Jwell Machinery Co., Ltd.; Shanghai Jwell Extrusion Foaming Technology Co., Ltd; Suzhou Jwell Machinery Co., Ltd; Suzhou Jwell Precision Machinery Co., Ltd; Suzhou Dyun Recycling Machinery Co., Ltd; Zhoushan Jwell Screw & Barrel Co., Ltd.; Purchasing Department, Equipment Testing Workshops, Seven Large Metal processing workshops, Two Nitride heat treatment shops and chrome-plating workshops.

Our company has imported a lot of advanced high-precision processing equipments from Korea, Japan etc. Such as Multi-station machining centers, CNC lathes and CNC milling machines. The company has taken the lead to pass the CE certification, IS09001: 2008 quality management system certification, adheres to the full implementation of "zero defect" quality control, strengthens the control of purchasing and supply, production technology, quality inspection, production marketing, capital arrangements, after-sales service and so on.

The main products are:

JWSB series of large-diameter HDPE / PVC double wall corrugated pipe, reinforced pipe extrusion line; Large Diameter HDPE Water Supply & Gas Supply pipe extrusion line; UPVC Large Diameter Pipe Extrusion Line; PP-R, PEX new type of water pipe extrusion line; PVC Wood-Plastic blend foam profile, plate and wide door panel extrusion line; UHMW-PE Ultra High Molecular Weight Polyethylene wear-resistant pipe, plate extrusion line; XPS extruded polystyrene heat insulation board production line; XPS (IXPE) cross-linked polyethylene foam sheet extrusion line; PE, PVC Aluminum & Plastic composite panel extrusion line; PE, PP, PS, ABS, PET, PETG single-layer, multi-layer plastic sheet, plate, film extrusion line; PC, PS, PE, PP, PMMA plastic sheet and plate extrusion line; PC, PP, PVC, PE hollow Cross Section plate extrusion line; One-way, two-way stretch geogrid Extrusion Line; All kinds of plastic extrusion machines, screw, barrel, chemical fiber coil head, POY, FDY High Speed Spinning whole-set Equipment and so on.

We have 25 years of experience in the plastic extrusion industry. with the deep understanding of the plastic extrusion technology and owning excellent metal processing ability, we are trying our best to be out of the common in the product quality. Accumulated manufacture & setting experience, grasp of the latest extrusion technology and in every aspect of production management full implementation of the ISO 9001: 2008 quality management system, which make us to be your trusted partner.

Our company always put the customer's benefit on the first place. Because we believe: Customer's success is our future. "Excellent quality, perfect all" is our quality policy, is the direction for all staff's efforts. 'Be honest' is the core idea for us to contribute "Jwell lives Century ". For decades, our products are sent throughout the whole country and exported to Russia, South Korea, Indonesia, Vietnam, Japan, Germany, Iran, South America and other countries and regions, that our products are well received by users.