Hot Runner System Injection Plastic Cap Mould Main Technique Parameters

Cavity/CoreMaterial :718H, P20, NAK80, 2316, S136, DIN1.2738, DIN1.2344, AISI H13

Product Material :ABS, PC, PP, PVC, POM, PMMA, PS, PE, PET, Rubber, Silicone,PA,PBT,PEI,etc.

Base :LKM , DME, HASCO, etc.

Structure :2 plate mold, 3 plate mold, core pulling mold

Runner System :Hot runner, Cold runner

Cavity :Single cavity, multi cavity by requested

Finish :Corrosion word, Mirror finish, Brushed

Longevity :0.5-3 million shots

Mould standard :HASCO, DME, MISUMI, or by requested etc.

Software :CAD, Pro-E, UG, solid works, etc.

Tolerance :± 0.02mm

Design Time :3-7days

Sample time :3-7days by express (DHL, TNT, etc.)

Main Technique :Milling, Grinding, EDM, Wire-cutting, Engraving, CNC, and 2.5 Dimension test, etc.

Manufacture time :3-7 weeks, depends on mould structure

Packing :polywood case, or by request

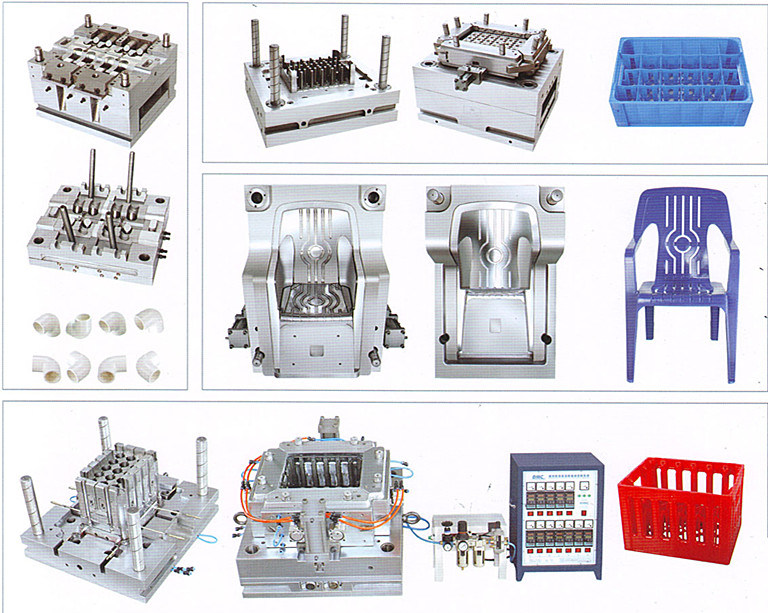

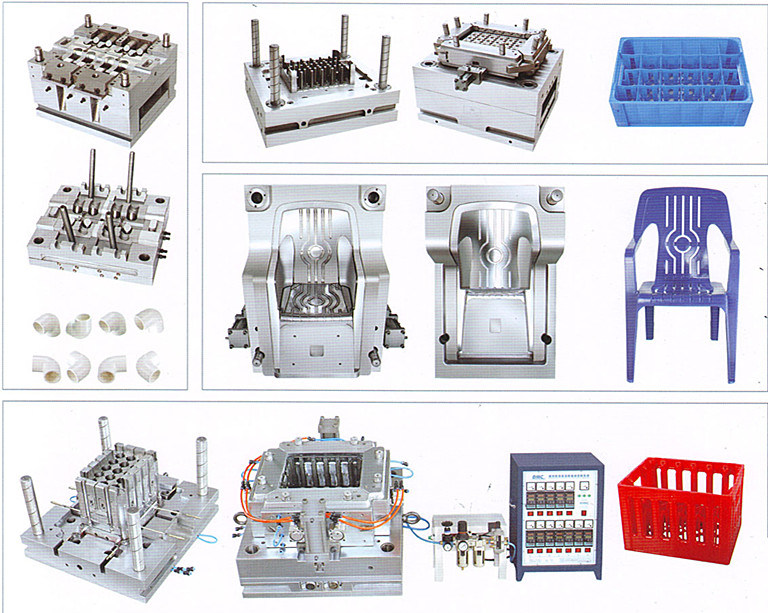

product photos:

Suzhou Forstec machinery Co., Ltd is located in zhangjiagang city Yangshe economic development zone.

We company is mainly dedicated to the production and trading issues for the blow molding machines. The machine is suitable for the production from 5 ml to 1000 litres of plastic bottles, bucket, cans, tool bag, car parts, unique shape insulating hollow seats, the car, tray, packaging barrels and hollow products. According to the need we can be configured single-mode head, dual mode head, three die head, four die head, six die, single, double, three, four, five, six layer modular top layer. For the users can make suitable for processing various special and special raw materials bottle blowing machines, blow molding blow molding machines. Such as PE, PP, PC, PA, PS, ABS, EVA, PETG, EVOH, PVDC, characterization, PPE, POM, TPE etc products of the production. The company product widely sales Britain, Australia, Brazil and 55 countries and the area, deeply trusted by customers domestic and abroad.

The company always adhere to the "collaboration, and the operation tenet" together with the customer, and the user, a hollow out, realize the development, improve the molding technology profession competitive power. At the same time the company always adhere to the "innovative design, fine manufacture, continued to improve, for global customers with first-class products and service" the quality idea, make product quality, provide satisfying products for market. Strive to continuing innovation and accumulation in outreach, LED by a combination of comprehensive form, the comprehensive strength of the modernization of the strong excellent enterprise.