***We provide:

Our services range from pre-sale consultation to a complete plant setup including machinery and peripheral equipment planning. From preform design to blow molding, we offer complete service.

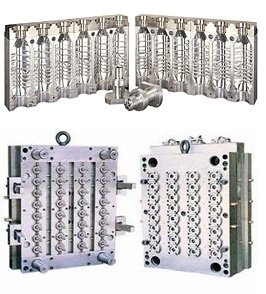

PET Preform mold: 4\8\16\32\48 civilities

PET Blow mold: 1~ 9 civilities

***PET Stretch-blow Mold:

We employ state-of -the-art CAD / CAM technologies to design and build high-quality tooling. We supply blow mold tooling by customer's demand for an increasing variety of markets applications ranging over wide-mouth jars, cosmetic and detergent bottles, pharmaceutical bottles, soya sauce and edible oil bottles, double seam can, bottled water, heat-resistant bottles, and CSD bottles

***PET Preform Mold:

Molds are designed for high performance using alloy steels and stainless steels, which guarantee maximum precision, high stability, and long life.

Using sophisticated and very fast systems, we support customers from preform to bottle design, to optimize the functional and aesthetic, demands of the container.

Profiled core and cavity cooling channels increase the heat transfer coefficient, resulting in greater efficiency and minimized cycle times.

Manufactured to very high standards and optimized for preform production, our molds have a service life of several years before refurbishing becomes necessary. Mold design makes service and maintenance operations fast and easy.

Our design standardization provides maximum application flexibility and rapid changeovers.

***Cap Injection Mold:

Preform Injection Mould from 1 cavity for wide mouth jar and gallon bottle preform up to 48 cavity narrow neck preform mould;

Tube blank is designed with the help of computer, which surely contributes to the increasing of yeild of bottle;

Employed internationally advanced two-step dual taper locating technology. Each cavity self-locks independently to ensure low decentration of product;

Core and cavity are made of special mold steel after preheating treatment in the original factory in Sweden. Individual temperature control of all cavity;

Lip cavity is made of imported nitrated steel, which is of high hardness and long service life, in accordance with international standard;

The excellent hot runner design assures uniform heating and greatly improves the quality of plastic product;

Standard inter-changeable mould components;

The life of mould is more than 2 million times.

Hot runner and temperature controller system:

1. Hot runner employs PID controlling system which features automatic compensation and automatic protection, and contributes to the prolongation of lifetime of electric heater;

2. The precision of temperature controlling falling within 1 centi-degree, which ensures to avoid plastic in the hot runner being burnt, resulting in a yield of up to 99% and more;

3. Ultra nozzles are designed to be maintenance-friendly. Nozzle tip inserts, heaters, tip insulator, and thermocouples are easily accessible and can be replaced while the hot runner is mounted in the machine, which minimizes down-time and reduces maintenance cost.

Core and cavity:

Core and cavity in mould are top materials. All the parts are processed on CNC machine tool with high precision, especially the plates, the tolerance is less than 0.05mm. And all parts are treated by heat treatment strictly, to ensure their intension and life time good enough. After the treatment, the intensive neck ring and core hardness can be HRC48~52, the hardness of cavity can be HRC44~48.

We are the manufacturer and supplier of plastic packaging machinery from China for more than 15years. We could offer not only complete package service from preform, bottle shape design, and equipment suggestion but also injection and formation technique transfer to customers to invest the minimum capitalized cost in equipment and develop the maximum economic benefits.

All plastic machinery and accessaries you interested, please feel free to contact us. We will offer you the machinery with best quality and most favourable prices.