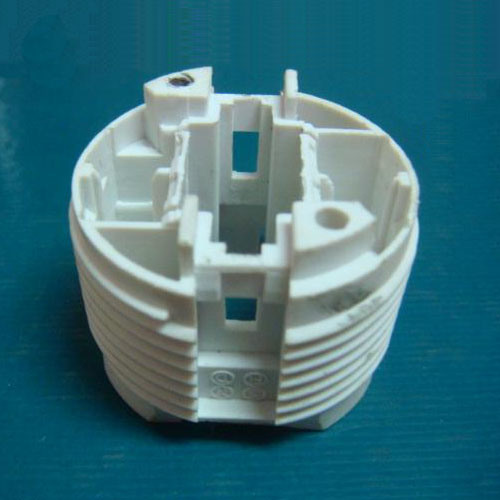

Injection Mould for Plastic Toliet Casing

| Price: |

US $ 0.6-2.6/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

10/Piece |

| Pay Type: |

L/C,T/T,D/P,Western Union |

We are professional mould manufacturer and as well as produce products for more than 10 years.

SGS certification we got

Company brief introduction:

1. Over 10 years experience

2. Highly qualified engineering team

3. Competitive price

4. High-tech development direction

5. SGS certification

Photoes show of company:

?

Mould description?:

SGS certification

1. Steel of Cavity and core: 2738

2. Mold base: LKM

3. Cavity: 1x1Cavity

4. Mold gate way: Yudo hot runner

5. Cooling system: Enough cooling

6. Surface: Mirror polishing

7. Tolerance: 0.02mm, 2D/3D control

8. Mould life: 1, 000, 000 shots

9. Finishe time for first sample: 40 days.

Key Specifications/Special Features:

In order to make sure doff automatic and without any eject mark, must be arrange high Polish for this Plastic Injection Mould/Mold. This rack choose PP material, then advice choose hard enough steel

1. Customized designs, sizes and frames are accepted

2. Mould steel: NAK80 forging for cor and cav, LKM for moUld base (customized)

3. Mould treatment: Final treatment for cor and cav plates by vacuum queching to 38 to 42deg; (whole plates 0.3mm hardness)

4. Mould cavity: 1*1

5. Mould software: Choose UG for 3D design, AutoCAD for 2D drawing, mould flow for runner analyze

6. Mould size: 600 x 500mm (depends on client's machine upon changing mold size)

7. Mould fix machine: 350T on injection molding machine

8. Plastic material: PP (on normal choose PP)

9. Mould cycle time: 32 seconds/shot (without cool water when test this mold)

10. Mould doff way: Automatic by ejectors and air spring (Hasco standard)

11. Mould lifespan (minimum): 1, 000, 000 shots

12. Mould base: Copy standard mold base

13. Mould gate way: Hot runner (customized)

14. Mould packing: Standard wooden case

15. Minimum mould order should be one set

16. Mould shipment will be arranged within seven days after confirm amples and received balance

17. After product, if needs long time stay, should put oil (butter mix benzene) on the cor and cav, slider's surface prevents rust, with free spare parts during mould minimum life and technical Aegis.

Features:

1) We can provide plastic mould for various parts according to your requirements

2) We own CNC processing centers, CNC spark working machinery and various advanced mould tooling equipment. We also have established a CAD / CAM / CAE mould design and development center.

3) Our quality, price, after sale services are really competitive

4) Our range covers from eletrical accessory, auto parts, household appliance, computer accessory, medical appliance, car accessory, digital&security parts ect.

|

Item |

High quality best price plastic abs products |

|

Material |

Top grate Acrylic, PMMA, PE, PVC, PP, PETG, PC, PS, HIPS, ABS ETC |

|

Main workmanship |

Vacuum forming, Thermoforming, CNC cutting, spary painting, Silk screen, etc |

|

Product characteristic |

1. Elegant contemporary design |

|

2. With SGS, BV, RoHs standards |

|

3. Any design and dimension available |

|

4. High strength, good toughness |

|

5. Almost weatherability and chemical resistance |

|

6. Stable color under outdoor exposure |

|

7.15 years OEM experience |

|

8. Easy to maintain and clean |

|

9. Strong plasticity can be easily shaped and processed |

|

Singular packing |

PE bag+ bubble package+ inner box+outer carton |

|

Outer packing |

Corrugated carton, shipping marks is made as customer' s request |

|

Payment terms |

30% T/T in advance, the balance paid before shipment |

|

Sample lead time |

3~5days |

|

Remarks |

1. Size, colors, packages can be customized |

|

2. OEM and ODM orders are warmly welcome |

|

Relevant products |

thermoforming plastic parts |

|

Our Advantage |

1) 15 years experience in manufacturing and exporting, service will be more professional |

|

2) 24-hour hotline, service more swiftly |

|

3) Large-scale production line, more rapid delivery |

|

4) Supporting deep processing, products diverse |

|

5) Advance equipment, the quality are perfect |

|

6) Professional foreign trade operations, services are more circumspect |

| Prod Model: |

WS-85G |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Plastic Material: |

Any Kinds Are Available |

| Surface Finish: |

Polishing and Texturing Are Available |

| Dimension Tolerance: |

ISO 2768 Unless Specified |

| Mould Standard: |

Hasco, Dme and Misumi Available |

| Shaping Mode: |

Injection Mould |

| Application: |

Home Use |

| Installation: |

Fixed |

| Process Combination Type: |

Compound Die |

Wishsino International Group Ltd.(Shenzhen), is a group of team to serve mold tooling and injection molding by OEM\ODM\New Concept Eruption, strong R&D proficiently performs project design and development, engineering and troubleshooting, plastic and metal.

WISHSINO, founded in 2001, located in Shenzhen, southern part of China, neighboring HongKong, very convenient with transportation and shipping.

WISHSINO, shown itself to all over the world as professional manufacturer of injection mold and plastic parts:

1. Tooling workshop, equipped with CNC, EDM, lathe, wire-cutting machine, grinding machine, drilling & boring machines, etc, professionally tool and manufacture molds according to customer´'s drawing, samples, tooling drawing can be shown to customers before actual tooling which profiles tooling structure, such as, slides, injection gate, cooling system, insert, cavity status.

2. Injection workshop, 24 injection machines in-house, 20 injection machines with partners, running from 80T~ 1600T, injection weight running from 60g~13000g, can serve all kinds of plastic material, ABS, PC, PP, PMMA, PVC, EVA, etc, overmolding is also done in-house, quality control and punctual production schedule guarantee the leadtime of transportation and shipping without compromising customer's expectation!

3. R&D, strongly staffed with veteran engineers who can proficiently perform product design and develop by OEM\ODM\New Concept Eruption, product ranges from auto field, lab accessories, LCD/LED plastic & electronic, and any other fields, etc, materialize the concept to actual product with lowest cost is the biggest strong-point of R&D's capacity, quick design and feedback in English help move project to success at proudly quick speed.

4. After-market service, our company owns the principle for customer that quality first, customer first, we are responsible for all defects or loss resulted from the goods we manufacture and ship, and correct the method to improve all quality up to or beyond customer's expectation.

5. Stamping partner, can supply all kinds of stamping parts but with competitive price, professional team with strong capacity of sheeting design and manufacture can produce products up to the spec exactly.