What is die casting?

Die casting is a versatile process for producing engineered metal parts by forcing molten metal under high pressure into reusable steel molds. These molds, called dies, can be designed to produce complex shapes with a high degree of accuracy and repeatability. Parts can be sharply defined, with smooth or textured surfaces, and are suitable for a wide variety of attractive and serviceable finishes.

Die castings are among the highest volume, mass-produced items manufactured by the metalworking industry, and they can be found in thousands of consumer, commercial and industrial products. Die cast parts are important components of products ranging from automobiles to toys. Parts can be as simple as a sink faucet or as complex as a connector housing.

After more than 17 years, we have gained rich experience in manufacture and gathered a group of skilled workers and veteran engineers with superior engineering level. We are professional in producing injection mould, die casting mould, metal and plastic prototyping, sheet stamped parts, insert/over molds, multi-cavities mould, rubber injection mould, etc.

We design and make Die Casting Mold ourselves.

1. Mold Material: 8407, P20, SKD11 or per customer's requirements...

2. Mold Design: According to Technical Drawings or Samples.

3. Mold Lead Time: 20 ~ 30 days

4. OEM and ODM orders are all Welcomed.

5. High Quality & Competitive Price & prompt delivery.

6. Advanced equipment and excellent R&D Team, Highly skilled manufacturing process, Strict quality Control System.

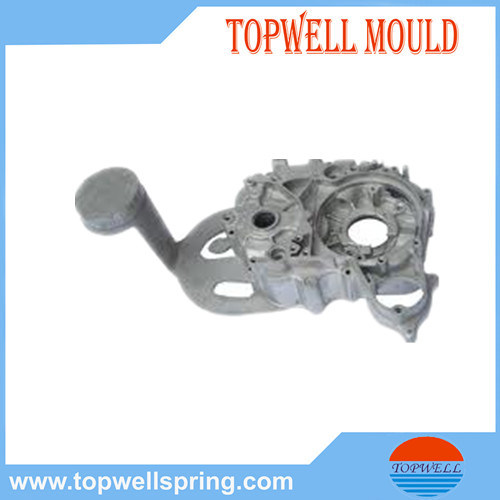

Die Casting parts

1. Product Material: Aluminum alloy or per customers' drawing needs.

2. Surface Treatment: Chrome plating, sandblasting, painting, anodizing, powder coating, electrophoresis, etc.

3. Sample time: 20~ 30days.

4.24-hour service with prompt reply

5. Process: Trim, grind, drill, CNC.

|

Item |

Aluminum/zamak die casting, Aluminum extrusions |

|

Designs |

As per the customer' s drawings or samples |

|

Material aluminum |

ADC12, ADC6, A380, Al-Si-Cu Series, 6061 or as customer' s request |

|

Material zinc |

Normally Zamak#1__Zamak 5 |

|

Product weight |

Available from 0.1kg to 30kg |

|

Tolerance |

: +/-0.01 mm |

|

Processes |

Casting, Deburring, Machining, Surface Treatment, Packing, all per request. |

|

Production Equipments |

50T-1800T aluminum die casting machinery |

|

Main machine used |

Die casting equipment, CNC center, lathe, milling, etc. |

|

Advantage |

Advanced equipment and excellent R& D Team, Highly skilled manufacturing process, Strict quality Control System. |

|

Surface Treatment |

Sand blasting, Zinc/chrome plating, Powder coating, anodizing, Shot Blasting, Chrome Plating, Nickel Plating, Hard Chrome Plating, Painting, electrophoresis, as well as heat treatment^ |

|

Application |

Auto parts, motorcycle parts, medical parts, pump parts, machinery parts, valve parts, tool parts, furniture parts, lighting parts, ect. |

|

Applied software |

PRO/E, Auto CAD, Slid Work, CAXA, UG, CAD/CAM/CAE |

|

Quality Certification |

ISO9001, ISO14000, TS16949 |

|

Packing |

Usually carton packaging, or PVC bag with a label. Specifically per customer needs. |

|

Service |

High Quality & Competitive Price & prompt delivery. 24-hour service with prompt reply |

Shenzhen Topwell Mould Technology Limited was incorporated in 1996, has evolved to be one of the leading customer injection molders of our region. Topwell engaged in the development, design and manufacture of precise plastic mould and plastic parts, and specialize in offering all-around service for customers such as the design and fabricating of tooling, injection and painting. The company is including R&D center, tooling, moulding, silkscreen, spraying workshops and assembly line.