We specialize in the field of custom metal fabrication for over 10 years with annual output value $32, 000, 000. It can prove our production capacity sufficiently with 300 workers and 90000 square meters factory area as well as lots of equipments

In addition to CE and BV mark of the products, we have won quality certificate in accordance with ISO 9001: 2008 rules.

The products shown hereby are only used to present the scopes of our manufacture capacities, not for sale. If our products are interesting for you, please leave us your brief inquiry with detailed drawings, our professional team will reply to you as soon as possible.

|

Main products |

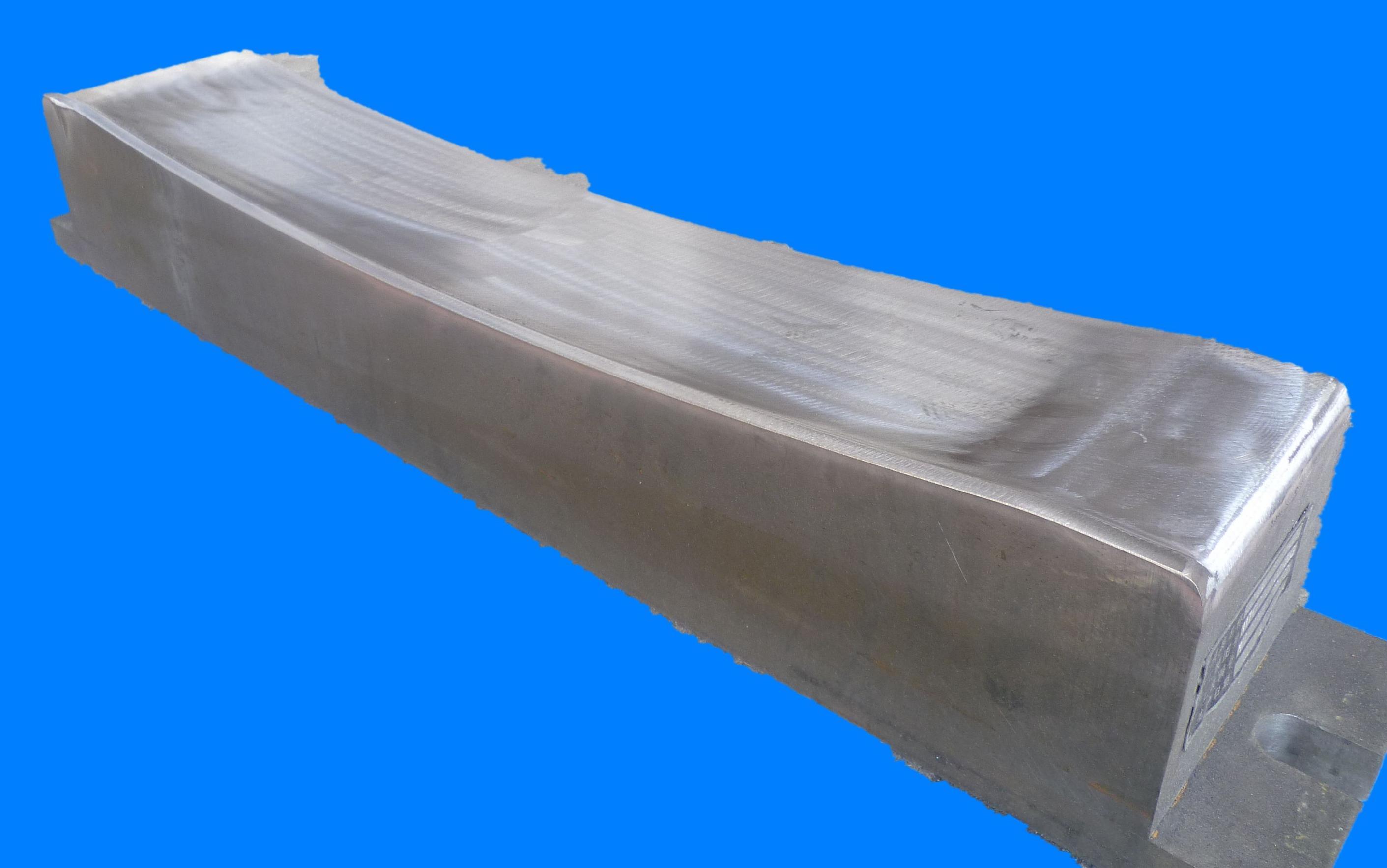

Custom metal fabrication , parking system , lift platform , steel structure, auto parts, fifth wheel, garage, fasteners, crane parts, elevator parts, machining parts, moulds |

|

Material |

carbon steel, stainless steel, aluminum sheet, copper |

|

Procedure |

Cutting,stamping,punching,threading,bending,welding,grinding,machining,surface finish |

|

Surface finishing |

zinc plating, hot dipped galvanized, powder coat, e-coat, polishing,chrome plated,nickel plated,anodized |

|

Advanced equipments |

2000T hydraulic press machine, 1600T hydraulic press machine, CNC machining center , CNC laser-cut machine , CNC flame-cut machine, CNC bending machine, CNC boring machine, punching machine, Welding robot , powder coat finishing line ,plasma cutting machine, hacksaw cutting machine, rolling machine and so on. |

Qingdao Lianhai Hydraulic Machinery Co., Ltd has won CE, BV, SGS mark of the products except quality certificate in accordance with ISO 9001: 2008 rules.

We specializ in the design, research and manufacture of car lift, parking system, lift platform, steel structure, mould and auto part as well as other metal fabrication etc for over 10 years.

We are a comprehensive manufacturer, and are well equipped with advanced machines and professional engineer teams capable of producing high quality products.

As one of OEM leaders, we continue to experience rapid growth in various ways.

To ensure high-quality and our commitment to promoting the design, manufacture of our products, we are dedicated to hiring skilled employees, selecting material strictly through quality control processes, testing the products carefully by our experienced engineer teams before delivery. Moreover, all of our products have been widely accepted by our clients through the world. Our exclusive target is to offer superior products and service for our worldwide customers and ensure complete reliability of operation. And all our policy is just aimed to provide complete satisfaction for our clients, too.

You are welcome to have a visit to us soon and evaluate our production capacity further.