Liquid Tire/Tyre Mould Making Silicone Rubber

| Price: |

US $ 10.49-13.78kg |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

100kg |

| Pay Type: |

L/C,T/T,Paypal,Western Union |

liquid tire/tyre mould making silicone rubber1. Application for liquid tire/tyre mould making silicone rubberliquid tire/tyre mould making silicone rubber is mainly used to make soft silicone products, such as sex toys, silicone dolls, love dolls, silicone mask, body organs, body breast enhancers, shoulder pads, paster, trackion, mask, etc.2. Features for liquid tire/tyre mould making silicone rubberliquid tire/tyre mould making silicone rubberbe used for a long period and maintain softness and elasticity within a temperature range of -65° C ~ 200° C with the characteristics of excellent electrical performance and chemical stability, waterproof, ozone and climate resistance, non-corrosiveness, physical inertia, non-toxic, odourless, low linear shrinkage, easy operation, etc. 3. Using instructions for liquid tire/tyre mould making silicone rubberMix component A and component B evenly according to the mixing proportion of 1: 1, and can be poured after deair the bubbles. The operating time (5-10) mins depends on the temperature; The curing time is 20-30 mins at the room temperature; And the curing time can be reduced to 10 minutes with the temperature increased to 80~120° C. The operating time of the room temperature quick drying type is less than 20 minutes and the curing time is 0.5 hour. The product can be produced in skin color, yellow, etc. According to the customer's requirements.ert4. Precautions for liquid tire/tyre mould making silicone rubberSkin Safe Silicone Rubber for Silicone Masks Making is platinum-catalyzed silicone rubber, water, impurity, organic tin catalyst, acid, alkaline and other organisms containing sulfur, phosphorus and nitrogen will influence the vulcanization of the silicon rubber. So, please do not mix with or touch those substances during using.5.Datasheet of liquid tire/tyre mould making silicone rubber

3. Using instructions for liquid tire/tyre mould making silicone rubberMix component A and component B evenly according to the mixing proportion of 1: 1, and can be poured after deair the bubbles. The operating time (5-10) mins depends on the temperature; The curing time is 20-30 mins at the room temperature; And the curing time can be reduced to 10 minutes with the temperature increased to 80~120° C. The operating time of the room temperature quick drying type is less than 20 minutes and the curing time is 0.5 hour. The product can be produced in skin color, yellow, etc. According to the customer's requirements.ert4. Precautions for liquid tire/tyre mould making silicone rubberSkin Safe Silicone Rubber for Silicone Masks Making is platinum-catalyzed silicone rubber, water, impurity, organic tin catalyst, acid, alkaline and other organisms containing sulfur, phosphorus and nitrogen will influence the vulcanization of the silicon rubber. So, please do not mix with or touch those substances during using.5.Datasheet of liquid tire/tyre mould making silicone rubber| Model | HY-E620# |

| Appearance | Blue |

| Mixing Ratio | 1:1 |

| Operating time (Mins 25°C) | 30 - 40 |

| Curing time (Mins 25°C) | 4-6h |

| Curing time (Mins 60°C) | 2-3h |

| Hardness (A°) | 20±2 |

| Density ( g/cm 3 ) | 1.08 |

| Viscosity (CS) (Part A) | 30000 ± 5000 |

| Viscosity (CS) (Part B) | 5000 ± 500 |

| Viscosity (CS) (After mixed) | 10000 ± 2000 |

| Tensile-strength( kgf /cm2 ) | 100 ± 20 |

| Tear-strength (kgf /cm2 ) | 18 ± 2 |

| Elongation-break(%) | 350 ± 50 |

| Retractility(%) | ≤0.1 |

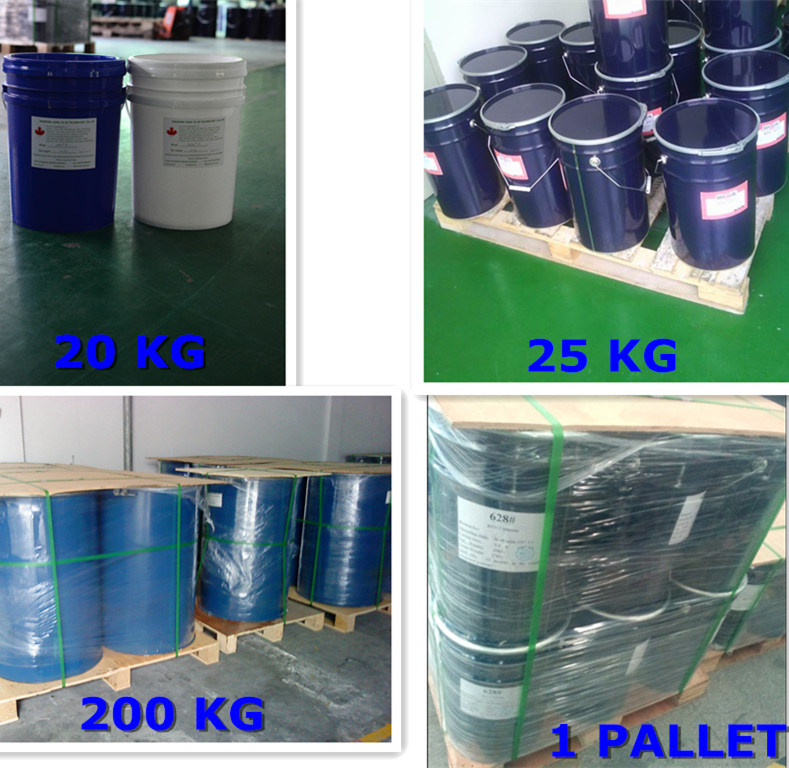

6. Package for liquid tire/tyre mould making silicone rubber

6. Package for liquid tire/tyre mould making silicone rubber 7. Transportation for liquid tire/tyre mould making silicone rubberRegard as non-hazardous goods, with shelf life of half year, hermetically sealed, with prevention from being in contact with acid, alkaline, and other impurities.If you want more information about liquid tire/tyre mould making silicone rubber, pls feel free to contact Ivy Mob: 008618938867558Tel: 075589948019

7. Transportation for liquid tire/tyre mould making silicone rubberRegard as non-hazardous goods, with shelf life of half year, hermetically sealed, with prevention from being in contact with acid, alkaline, and other impurities.If you want more information about liquid tire/tyre mould making silicone rubber, pls feel free to contact Ivy Mob: 008618938867558Tel: 075589948019

| Prod Model: |

E620 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Color: |

Translucent |

| Feature: |

Liquid |

| Sample: |

Available |

| Minimum Order Quantity: |

200 Kilogram |

| Purity: |

100% |

| Certifications: |

RoHS, MSDS, SGS, ISO9001:2000 |

| Type: |

Addition Cure Silicone Rubber |

| Mixing Ratio: |

1:1 or 10:! |

| Brand Name: |

Hong Ye Silicone Rubber |

| Place Of Origin: |

Guangdong China |

| Material: |

Silicone Rubber |

| Appearance: |

Liquid |

We are manufacturer spcializing in silicon rubber material, such as silicone gel, pad printing silicon, RTV-2 silicone rubber, HTV, RTV-2 room temperature sulfurated silicon rubber, silicon, shoe molding silicon, silicon rubber, manul molding silicon, liquid silicon rubber, LSR, pad printing silicone rubber, mixed iron-smelting silicon rubber, solid silicone rubber, methyl-ethenyl silicone rubber, molding silicone rubber, mold duplicating rubber for resin craft makers, special silicon for manual molding, shoe mold rubber, pad printing silicon, silicon oil, 107 base, DMC etc. For plastic toys factories. With a product line of tens of categories, we can offer quick copying with precise contraction ratio (up to two thousandth) for mold making. To reach the internationally leading quality standard with competitive price is our best ambition that merits your trust.

RTV-2 Mold making silicone rubber

[1] RTV-2 silicone rubber for mold making

RTV-2 molding silicone rubber mainly applicable to make the silicone mould for cultural relic duplication, architectural decoration, resin crafts, lighting ornaments, candles, statues, model design, product exploitation, etc.

[2 ]RTV-2 silicone rubber for pad printing

Pad printing silicon rubber is specially designed for silicon pads which requires to be exquisite, without impurity or granules. Silicon pad is a carrier which transfer printing the patterns on the steel plate onto the toy products' Surface. Pad printing silicone rubber is mainly used for printing irregular patterns of plastic toys, electroplating products, electronic toys, trademarks.

[3] RTV-2 manual mold silicon rubber

RTV-2 manual mold silicon rubber is mainly applied in manual mold design, PVC plastic mould, cement product mould, melting-point alloy mould, alloy toy crafts, plastic toy, craftwork, gift and stationery, big statue, cultural relic duplication, shoe sole mould production, pad printing orientation, electronic appliances vibration resistance, etc.

[4] HTV-2 Silicone rubber

HTV-2 silicone rubber is applied in metal crafts, hot stamping silicone roller, hot stamping silicone plate, mobile phone keycap, PC keycap, telephone keycap, TV remote control keycap, electronic products, silicone rubber products field, etc.

[5] Disc silicone rubber

Disc silicone rubber is mainly applicable to zinc aluminum alloy arts and crafts, imitation of gold and silver ornaments, fishing tools, bracelets, hanging ornaments, furniture fittings, decoration accessories, toys and gifts, etc.