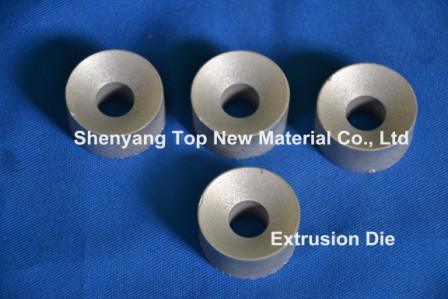

Our newly developed TiC base's metal ceramics possess comprehensive properties that can be applied to copper extrusion die and sealing spare parts where wear resistance and corrosion resistance are required. It can remains high hardness even at red heat, better tenacity and oxidization resistance, etc.

Usage: For extruding aluminum, copper or copper alloy rod

Material: Metal ceramic

Density: 6.30 g/cm3

Hardness: HRC 58-61

Bednding Strength: 700-1500Mpa

Peformance: Wear resistance, thermal resistance and corrosion resistance

Temperature resistance: Up to 1180 celsius degree

Lifetime: 6 times than the steel ones (3Cr2W8V)

Shenyang Top New Material Co., Ltd. Was established in 2001. Through hard work and dedicating efforts, our company develops quickly. Our company covers an area of 12, 000 square meters, including 8000 square meters of construction area of two workshops.

1. Powder metallurgy workshop:

The main products:

1) Copper-tungsten and silver-tungsten alloys for high pressure switch contacts; Spark electrodes and welding electrodes

2) Metal ceramics for moulding tools of copper squeezing, sealing rings where heat-resistance, corrosion-resistance and wear-resistance are required

3) Oil containing bearings where wear-resistance and high speed are required

4) High specific gravity metal alloys

Our workshop uses complete powder metallurgical equipment as well as machines for more advanced processing. These machines allow for a degree of accuracy, which can fully meet the demands for the further processing and production of other complicated spare parts.

2. Smelting and investment casting workshop:

With cooperation with super alloy laboratory of Metal Research Institute in Chinese Sciences Academy, we have ample equipment. Our equipment includes a vacuum furnace ranging a 25kg induction type to a 500kg half-continuous type. The cobalt base alloys, nickel base's master alloys and investment casting spare parts can be made to conform with any criteria, such as GH series, K series, STELLITE series alloys, all kinds of heat-resistance steel and super low carbon stainless steel. Some of these can be further processed by forging, rolling and drawing. In particular, the copper alloys requiring pressure testing or welding in the normal pressure are our advantages.

3. CNC processing center

Newly equipted with five CNC machines tools made in Japan, and most precise metal parts can be processed with international standard.

We have already passed the ISO9001: 2000 international quality and quantity system attestation. Our company offers cobalt-chrome-tungsten alloy and powder alloy products' processing and services.

Please do not hesitate to contact us for more information.