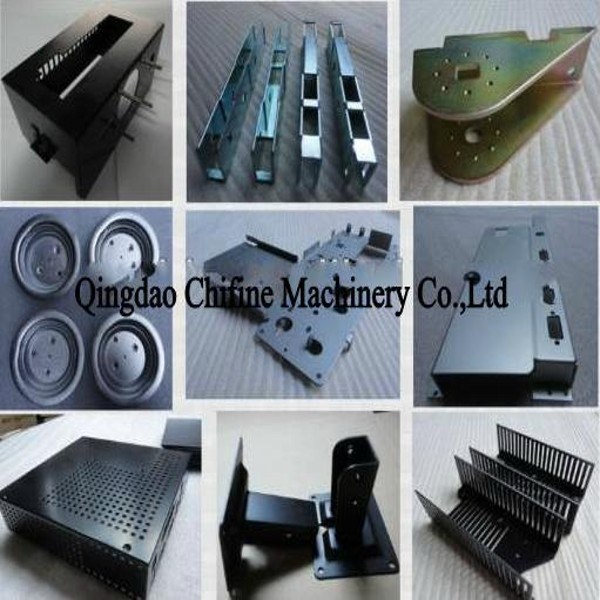

Metal stamping part

1. Scope: Full size

2. Ensure all products are 100% inspectioin before shipment

3. Prompt delivery

4. Customer-orientated design

5. Perfect Surface, smoothness, without burrs and impurites

6. Material: SPCC, SGCC, Stainless Steel, Carbon Steel, Mild Steel, Aluminum, Aluminium Alloy etc.

7. Applied software for specification drawings: PRO/E, Auto CAD, Solid Works and CAM/CAE.

8. Surface treatment: Zinc/Nickel/Chrome Plating, Galvanization, Powder Coating, Plastic Spraying.

9. Product range: Sheet metal fabrication, auto parts, motorcycle part, construction hardware, metal cabinet etc.

| Equipment | CNC stamping/punching machine, CNC bending machine, CNC cutting machine, 5~250 tons punching machines, welding machine, polish

machines... |

| Processed material | stainless steel, copper, carbon steel (according to customer' s

requirement) |

| Surface treatment | Hot galvanized, polishing, chrome/zinc/nickel plating, powder coating,

anodize... |

| Making process | Stamping, deep drawing, bending, punching, laster cutting, threading,

welding, tapping, riveting, grinding |

| Size | According to customer' s desing |

| Thickiness | 0.5mm ~12mm, or other special available |

| Standard | ANSI. API. BS. DIN. JIS. GB. etc |

| R& D | We support customer R& D make the file orimprove the design if you needed |

| Inspection | IQC, IPQC, FQC, QA |

| Mould | Depend on customer' s require to make the mould. |

| Sample confirmation | Before start mass production we will send the pre-production samples to customer for confirmation. We will modify the mould untill customer satisfied. |

| Products Scope | Funiture hardware, electronice hardware, construction hardware, sheet metal processing, machinery parts, hydraulic fitting |

| Packing | According to customer' s requirements |

| Certificate | ISO 9001 |

Qingdao Chifine Machinery Co., Ltd is One Famous Company in China Which Specialized in Various Metal Casting Products with Over 10 Years Experience Located in Qingdao China. It Covers a Comprehensive Range of Forging, Stamping, Sand Casting, Investment Casting, Die Casting and Machining and Was Widely Used in Agriculture Machinery, Motor Vehicle, Architecture, Railway and Engineering Chifine Has Accumulated Important and Valuable Experience in Design, Manufacturing and Customer Service Over These Years We Will Continue to Integrate Our Technical Superiority, Improve Process and Quality to Increase Market Share and Create More Brilliant Future.

Automative Casting Line:

• Material: Grey iron(GG20-GG35); Ductile iron(GGG40-GGG60);

Malleable cast-iron(GTS35-10/45-06/55-04/65-02, CTW35-04/05/06/07).

• Product Size: 0-1000mm.

• Weight: 0.2kg-100kg

Resin Sand Casting

• Material: Grey iron(GG20-GG35); Ductile iron(GGG40-GGG60);

Malleable cast-iron(GTS35-10/45-06/55-04/65-02, CTW35-04/05/06/07).

Steel casting(ASTM/UNS; DIN; JIS; NF; BS; ISO)

• Product Size: 0-1500mm.

• Weight: 10kg-5000kg

Shell Mould Casting

Shell casting is one of resin sand casting process.

It is suitable for thin-wall casting parts, be free from porosity.

• Material: Grey iron(GG20-GG35); Ductile iron(GGG40-GGG60);

Malleable cast-iron(GTS35-10/45-06/55-04/65-02, CTW35-04/05/06/07).

Steel alloy; Aluminum alloy; Copper alloy.

• Product Size: 0-500mm.

• Weight: 50g-100kg.

• Wall thickness: 4-20mm

Lost Wax Casting

• Advanced wax-injection-machine and tool to ensure accurate wax-patten.

• Stable temperature and humidity environment make the wax-patten no deformation.

• Material:

Carbon steel; Stainless steel; Alloy steel.

Grey iron(GG20-GG35).

Ductile iron(GGG40-GGG60);

Malleable cast-iron

(GTS35-10/45-06/55-04/65-02, CTW35-04/05/06/07).

Aluminum alloy; Copper alloy.

• Casting size: 0-500mm.

• Casting weight: 50g-100kg

Stamping and Forging Line

• Stamping and forging equipment: 16T-300T press machine

• Automatic transport forging line

• Material: Carbon steel; Stainless steel; Alloy steel.

Aluminum alloy; Copper alloy.

Machining Shop

Our machining shop located in Qingdao, using the latest CNC equipment to provide our customer with high quality products.

• Horizontal and Vertical Machining Center

• CNC lathe and normal lathe

• CNC drilling and milling Center

• Other assistant equipment