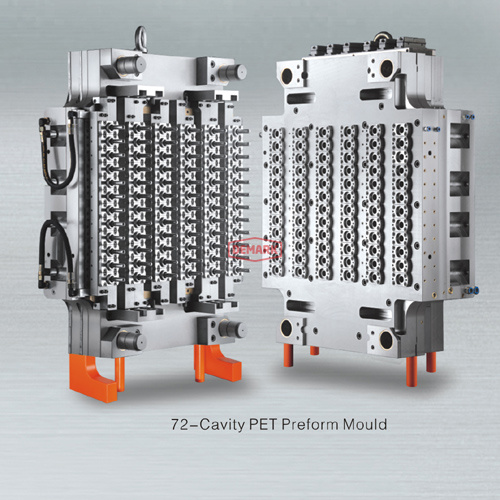

Demark 72 cavities pet preform injection molding system@(injection molding machine@injection moulding machine@injecton moulding system) uses a new part cooling and handling system, which features:

1. Cooling on the inner surface of the preform without using compressed air, unlike most post-mold cooling systems which only cool the outer surface

2. Optimized cycle utilization _ being mounted on the moving platen, the cooling system remains active for up to 85% of the overall cycle.

Demark pet preform injection systems are available from 280 to 500 tonnes (2800 to 5000 kN) and up to 72 cavities.

Demark pet injection systems offer:

1. Faster cycles

2. Reduced energy consumption

3. Smaller footprint

4. Improved repeatability

5. Rapid set-up

Features:

1. Two state plasticizing enables plenty injection quantity;

2. Take out plate with three working position insures sufficient cooling time and shorter cycle time;

3. High quality parts and accessories from world famous brands enable higher speed and precision;

4. Special screw design increases torque while brings down shear force to avoid degradation;

5. Accumulator from world reputable manufacture increases performance while brings down power consumption;

FelxiblePlatens

Flexible platens distribute clamp force evenly across the platen face.

Flexible platens:

1. Allow for lower clamp tonnage 20%

2. Decrease mold wear

3. Improve part quality

Injection Units

Demark systems offer both reciprocating screw (RS) and two-stage injection units. RS units offer the performance required for many PET applications while two-stage is appropriate for higher throughput applications.

PC Controls System

PC-based controls manage all functions of our PET production systems, with optional packages to integrate auxiliaries and downstream part handling equipment. Advantages include:

1. Faster cycle times

2. Improved shot-to-shot repeatability

3. Remote connectivity through ServiceNetLink

4. Control of molding system and auxiliaries from a single interface

Linear Bearings

Linear bearings support the moving platen directly on the machine base. This design reduces mold wear by improving platen alignment and perpendicularity, and provides a grease free molding environment.

Demark Holding Group Co., Ltd.,with working area of 140, 000 square meters and with capital of USD 50 million, is one of the most important suppliers in China, offering the proposal of PET whole line solution. It is a modern technological enterprise which combines technological design, manufacturing and marketing as one. Since established, Demark specialized in the area of PET packaging, mainly offering the clients PET bottle factory project, from preform design to bottle blowing. Our products include PET injection molding line, needle valve preform mold, fully automatic bottle blow molding machine, PET blowing molds etc., by 20 years' experience.

Fully automatic PET blow molding machine designed and produced by Demark Machinery has 4 kinds: DMK-R series high speed rotary fully automatic blow moulding machine, SFL series servo energy saving fully automatic blow molding machine, normal economical DMK-L series linear blow molding machine, big bottle series fully automatic blow molding machine. Adopting the European world leading technology for bottle blowing machine, the DMK- R series fully automatic rotary machine is close to the international standard after many years of test and verification and with high cost performance.

Demark Machinery is specialized in PET preform molds, PET LINE and blowing molds. It is one of the earliest companies adopting needle valve hot runner system. We offer preform molds and PET Line under 144 cavities. We can also take the project for the remake of injection molds for the famous international and domestic companies, such as offering cold half part, hot runner, the core, the cavity and screw. Our blowing molds can not only be equipped with our bottle blowing machine, but also be equipped with other famous blow molding machine such as SIDEL, KORONES, SIPA, SIG and ASB. We are one of the few domestic companies whose products can take place of imported PET injection molds and rotary blowing molds.

We imported CNC from Germany, America, Japan with advanced equipments like imported turning center, electric scintilla and some other equipments, totally about 80 sets.

1) Germen DMG five-axis CNC machine center: 4 sets

Germen DMG (CTX beta 1250TC ) turning and milling composite machine: 2 sets

2) American five-axis CNC center: 1 set

American "HASS"four-axis 3+1 CNC center: 1 set

American "HASS"three-axis CNC center: 2 sets

American HARDinge fine CNC: 1 set

3) Japan imported horizontal CNC center MAKINO A92: 1 set

Japan MAZAK fine MID. CNC center: 2 sets

Japan MAZAK fine large CNC center: 1 set

Japan MAZAK fine CNC: 5 sets

4) Swiss "AgieCharmilles" CNC 4-axis spark machine: 2 sets

5) Large CNC planogrinder: 2 sets

SCHLEIFRING CNC internal and external round grinder: 2 sets

SCHLEIFRING CNC plan grinder: 1 set

MID. and small grinders 5 sets each

6) EDM machine, wire cutting machine

EDM drilling machine, turning machine, milling machine, drilling machine, grinder abrasive finishing machine etc., totally for dozens of sets.

7) Haitian HTM-80H horizontal CNC center: 1 set (for blow moulding machine)

8) Taiwan imported large CNC boring and milling center: 5 sets

9) Germen fine 3D mapping instrument: 1 set, digital protector: 2sets, high speed laser making machine: 2 sets

The advanced equipment, high manufacturing technology and perfect quality inspection system assures strong protection for the precision of products. Complete sales and service line covers pre-sales, sales and after-sales. Our whole team insist always the idea of "customer first", and try our best to offer the most considerate service to our customer. Friends from various fields are warmly welcome to visit us.

Demark Machinery always insist the faith of building the world famous brand for PET packaging machinery, and continues to work hard for this booming market.