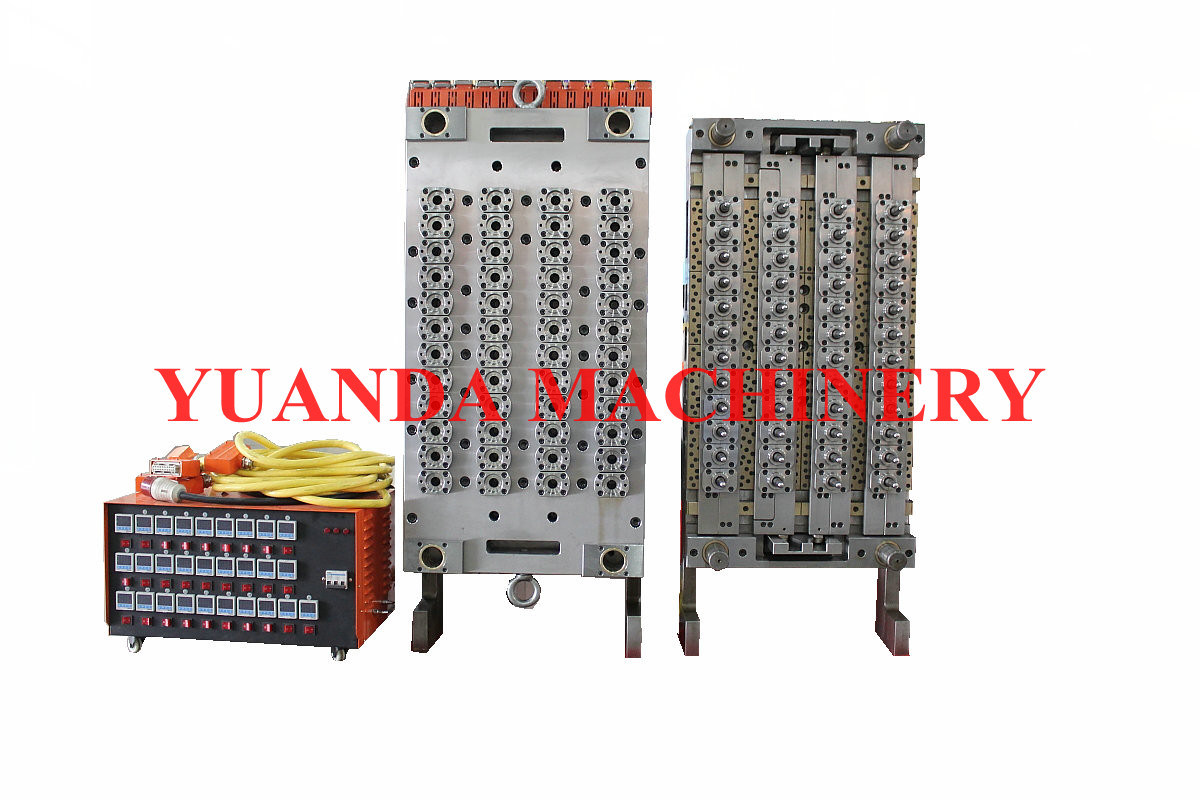

Needle Valve of No-Cutting PET Preform Molds

The new advanced hot runner with valve gate system for the micro-pitch preform mould have been introduced to the market, it helps the preform producer reducing the power consumption of the molds and Tonnage of the preform molding system. The number of cavities is up to 96 cavities for standard neck finishes, such as PCO 1881, PCO1810, and 30/25. The cam roller design for the thread splits helps operator maintenance freely.

Preform Mould Features

* Individual Valve-Gate unit with balanced hot runner system

Perfectly balanced hot runners ensure uniform melt flow and pressure in all cavities. The design of the melt channels minimizes shear and pressure loss, and provides a uniform flow to all cavities. Optimized heat distribution results in consistent AA levels across all cavities. An advanced valve-gate system has been used for closing and opening the gate of preforms. Reliable valve shut off function; Precise machining and low thermal expansion rate ensure the long working lift with less maintenance.

* Dual Tapers design for Lock

Individual dual tapers locking design for thread splits, lock ring and cavity that reduce moulds wear. It guarantees the longer mold lift time and the tight tolerance for the injection moulded preforms.

* Maintenance free roller cams

Roller cams make both the opening and closing actions on the thread splits; The bearing has less frication, makes sure the movement of the thread split plate smoothly, and ensures the longer working lift. This roller cam system guarantees the longer service time.

* Low crystallinity in the gate area of the preform

Balanced hot runners with valve gates for PET processing, expedite the effective heat transfer to the nozzle tips. This results in shorter start-up times and minimizes crystallinity at the gate area.

* Fast and efficient cooling

Turbulent water flow ensures fast and efficient heat exchange between prefoms and water. Separately water cooled neck rings lead to high preform quality and short cycle times.

* PVD coatings (optional)

Cores are TiN coated via a PVD process, to facilitate faster ejection of preforms and to prevent them from getting stuck to the core. This coating also permits higher injection rates, further reducing cycle time and providing the extremely wear resistant for the core pins.

* Precision machined and finished

Advanced machines and finishing techniques guarantee the minimum wall thickness within ± 0.05 mm and weight variation less than ± 0.5 % of preform weight.

YUANDA the professional PET Preform mould maker and tool designer in China

|

Cavities |

17g PET preform |

28g PET preform |

47g PET preform |

|

Dimension(mm) |

Weight(kg) |

Dimension(mm) |

Weight(kg) |

Dimension(mm) |

Weight(kg) |

|

2*2 |

345*390*466 |

370 |

345*390*486 |

450 |

345*390*511 |

500 |

|

2*3 |

410*390*466 |

440 |

410*390*486 |

500 |

410*390*511 |

550 |

|

2*4 |

475*390*466 |

510 |

475*390*486 |

600 |

475*390*511 |

660 |

|

2*6 |

605*390*466 |

650 |

605*390*486 |

730 |

605*390*511 |

800 |

|

2*8 |

735*390*466 |

800 |

735*390*486 |

900 |

735*390*511 |

1000 |

|

2*10 |

865*390*466 |

950 |

865*390*486 |

1050 |

865*390*511 |

1150 |

|

3*8 |

775*500*490 |

1250 |

775*500*510 |

2000 |

775*500*535 |

2200 |

|

4*8 |

855*600*520 |

1850 |

855*600*540 |

2000 |

855*600*565 |

2200 |

|

6*8 |

955*720*520 |

2370 |

955*720*540 |

2500 |

955*720*565 |

2700 |

|

7*8 |

1085*720*520 |

2765 |

1085*720*540 |

2950 |

|

|

|

6*12 |

1085*900*550 |

3500 |

1085*900*570 |

3700 |

|

|

YUANDA is one of the biggest manufacturers of Blow Molding Machine in China. YUANDA lie in Huang yan, Taizhou, Zhejiang, China. We are the member of Enterprise of China Plastics Processing industry Association, and professional manufacturing company of Two-steps PET BOPP Semi-automatic Blow Molding Machine, manual Preform feeding PET automatic blow and Aluminum Casting Mould. After over 10 years of efforts, we have obtained eight national patent techniques. Our company has been approved by the ISO9001 and CE certificate, furthermore, the quality of the machine is in sured by PICC.