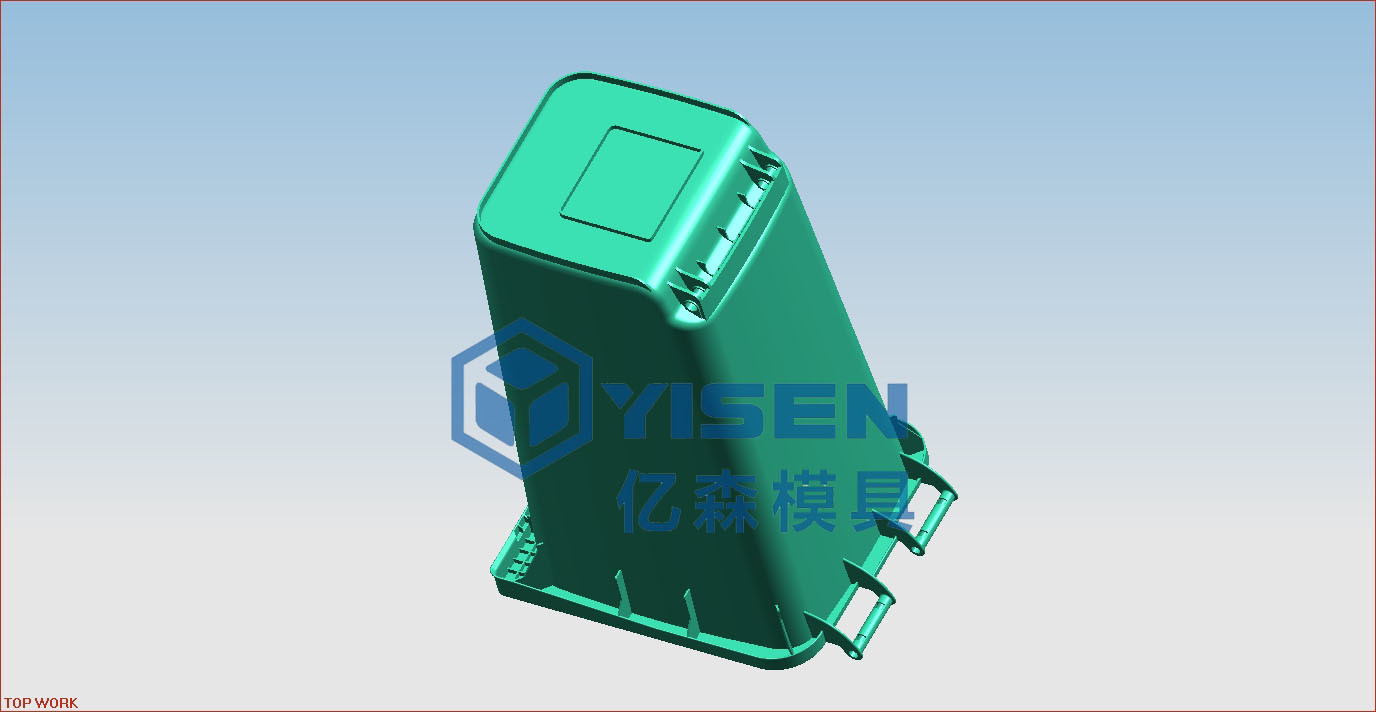

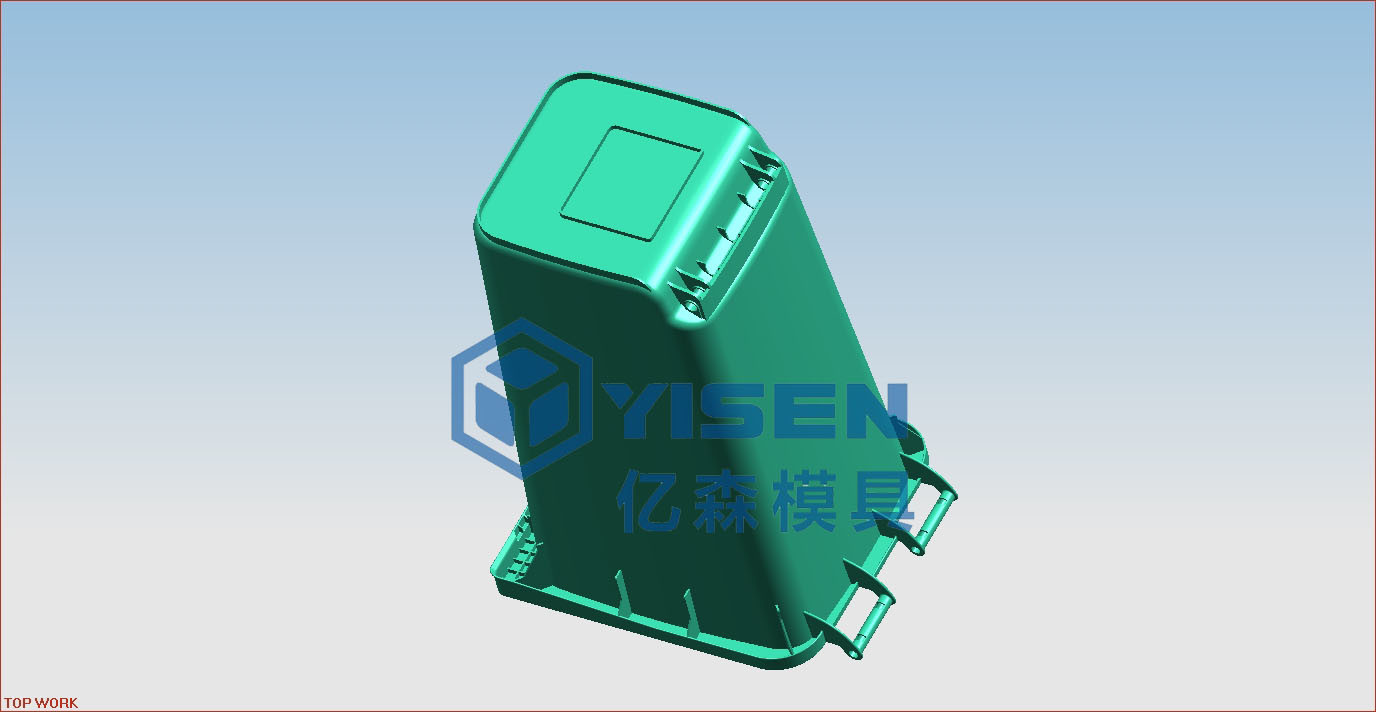

Plastic Dustbin Mould

| Price: |

US $ 10000-100000/Piece |

| Trade Terms: |

FOB,EXW |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

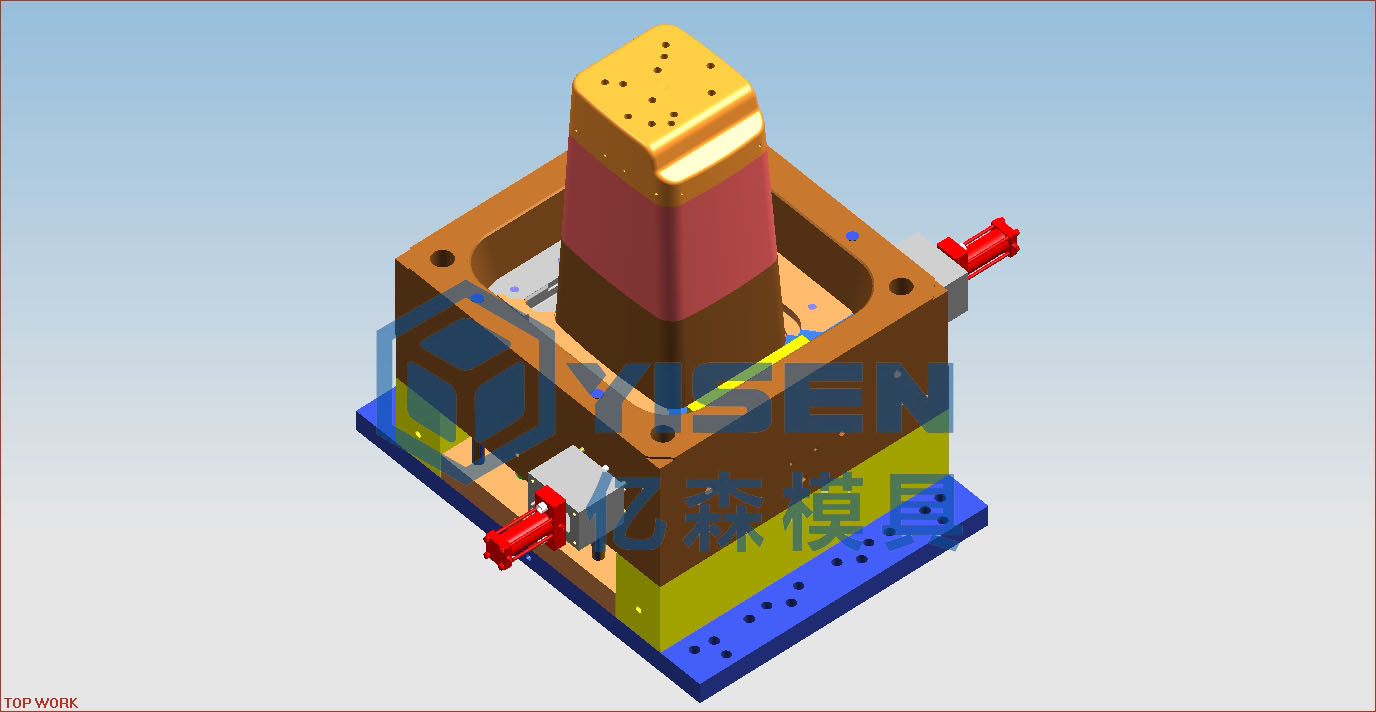

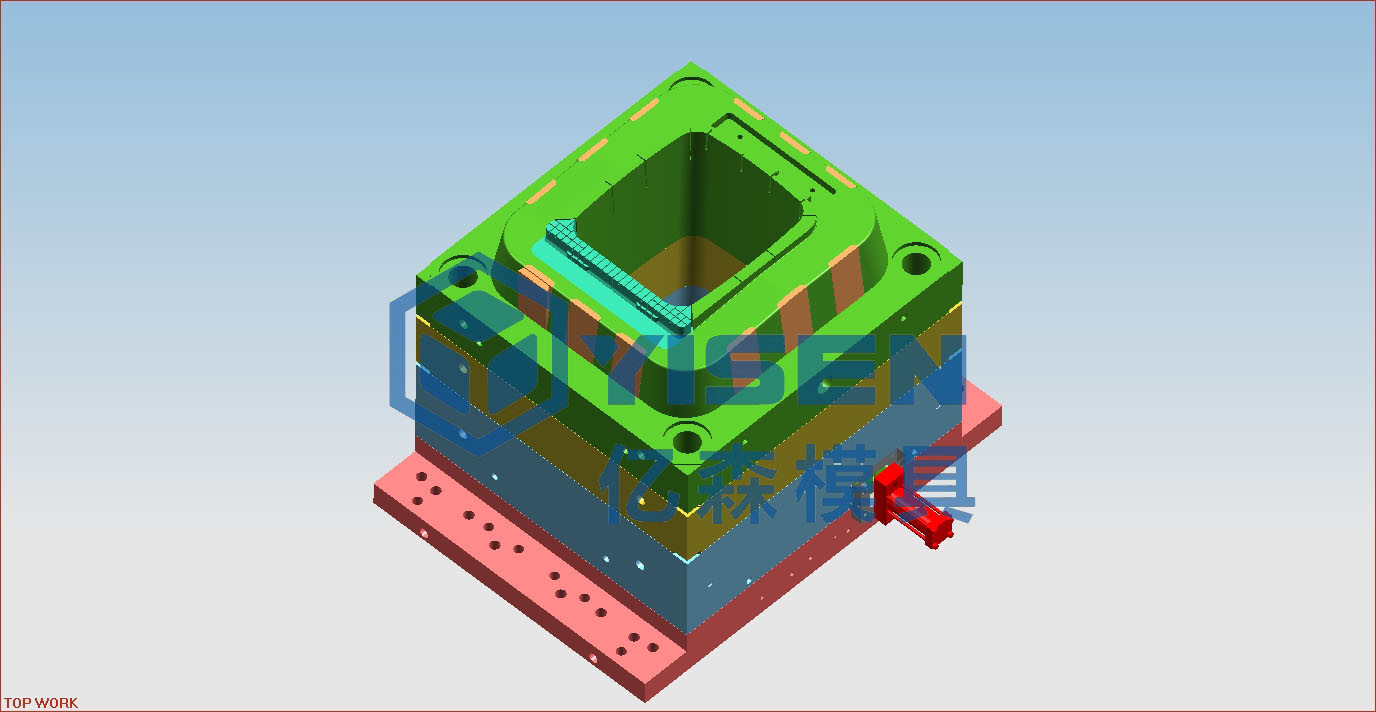

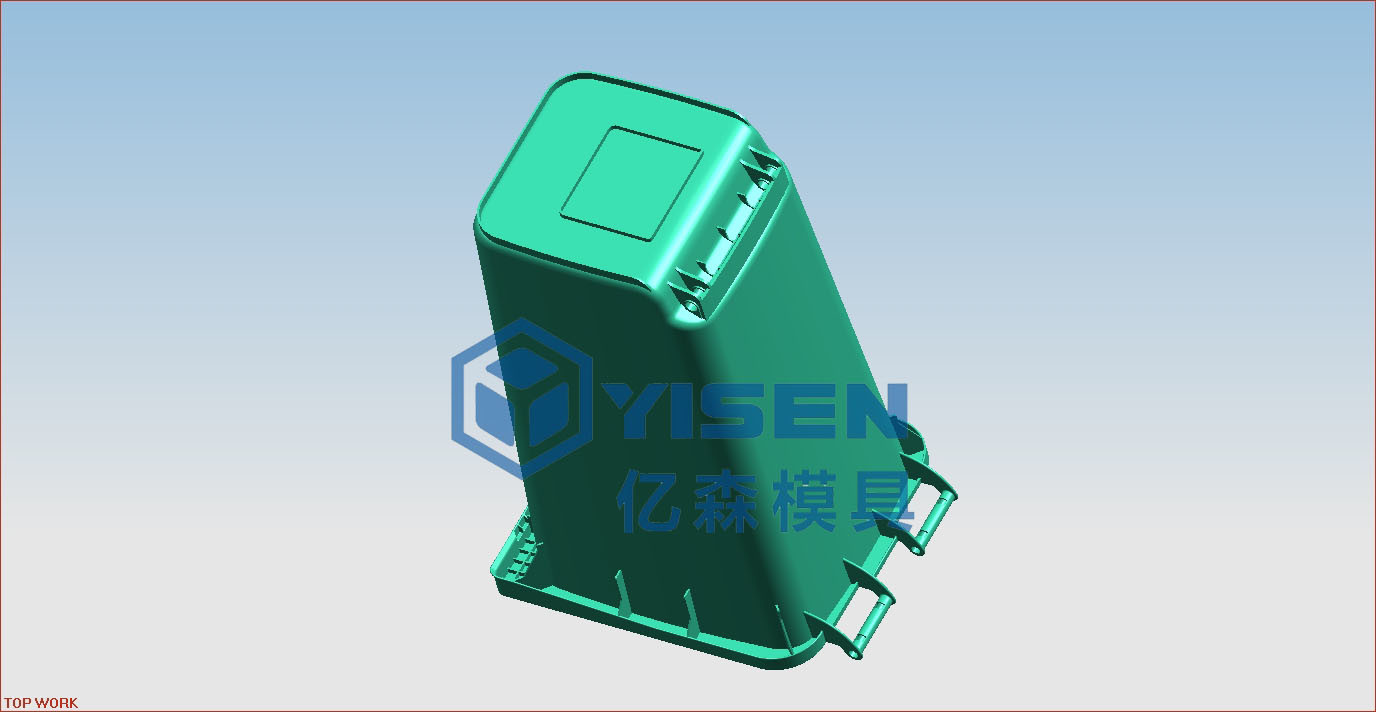

plastic dustbin mould

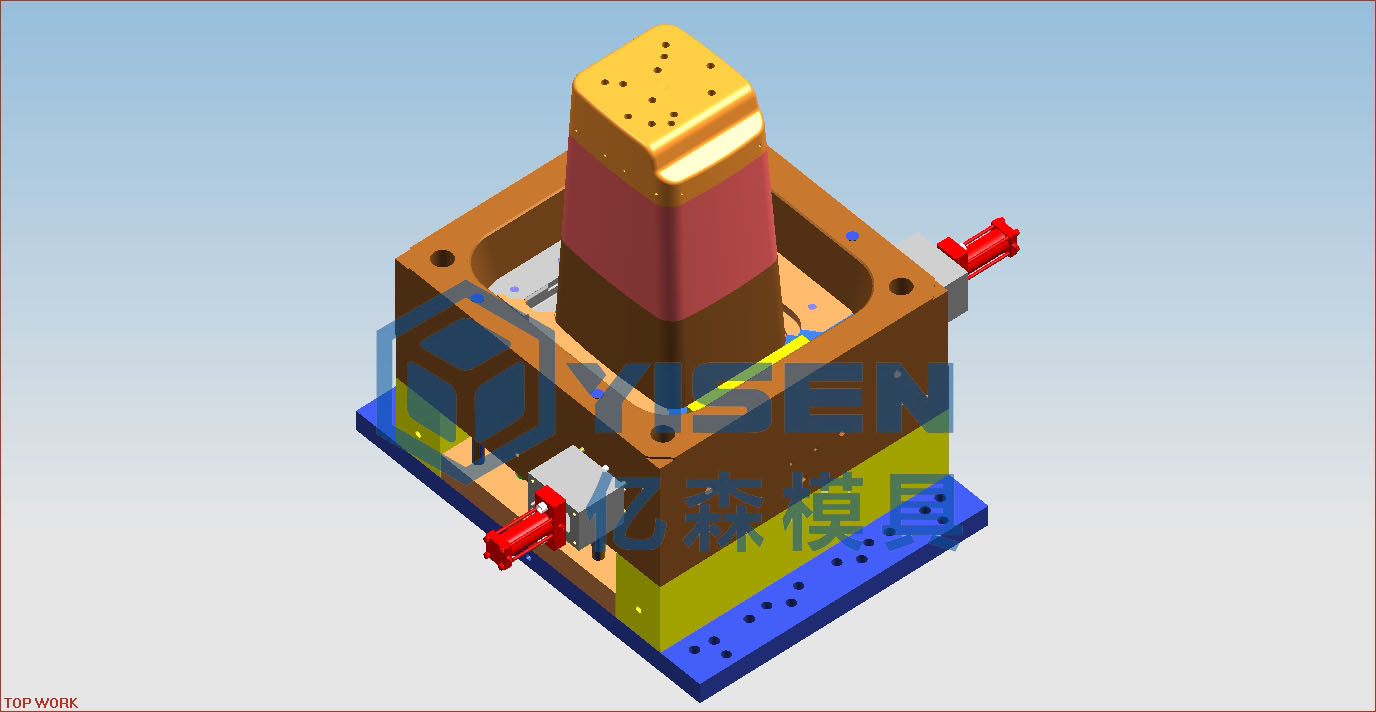

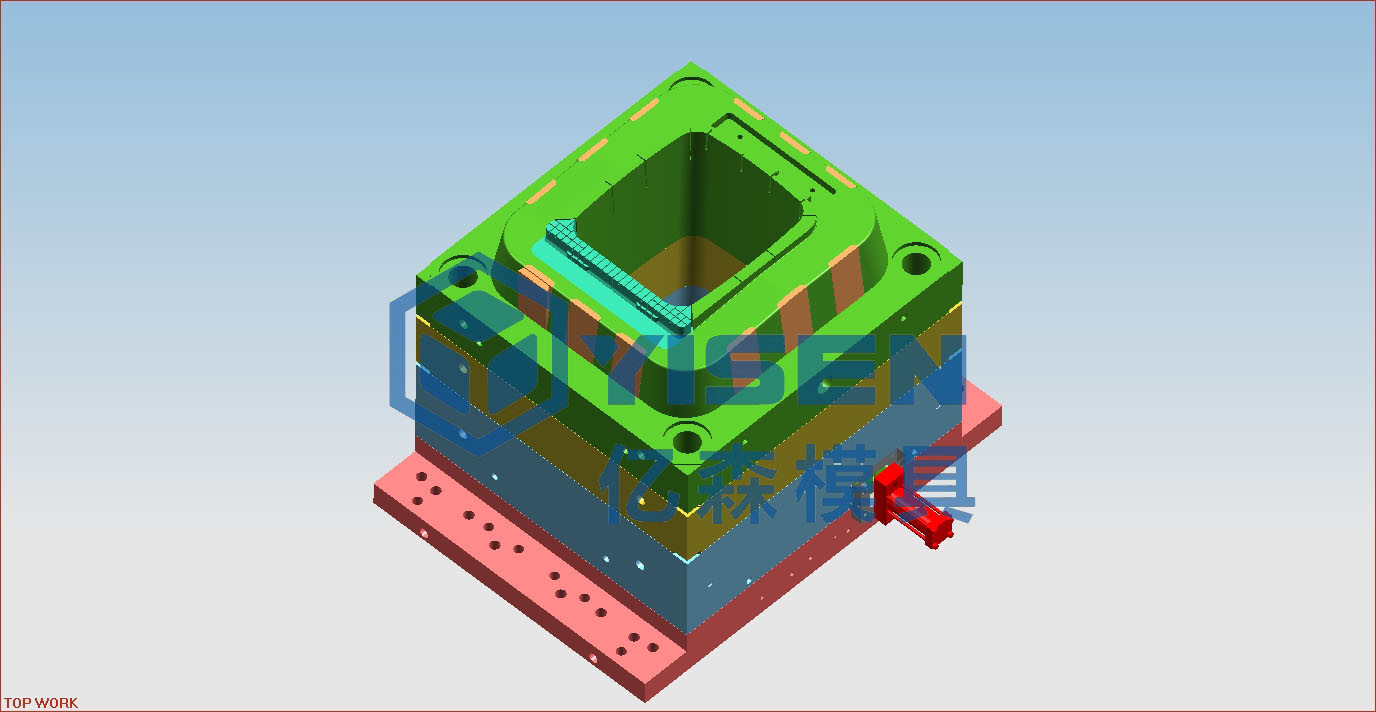

Nice mould cooling design

OEM & ODM mould service

Moldflow analysis report

Dust bin mold, plastic dustbin mold, recycle bin injection mold

Mould Name |

plastic dustbin mould |

Plastic Material |

PVC, PPR, PP, PE, ABS, POM, PPH etc. |

Product Size: |

|

Mould Cavity NO. |

Customized |

Steel of Cavity &Core |

DIN1.2316/DIN1.2738/DIN1.2344/718/P20(optional) |

Mould Making Standard |

LKM or DME or Harsco |

Hardness of Carity &Core |

32-50 HRC |

Hardness of Wear Parts |

50-60 HRC |

Suitable Injection machine |

|

Moulding cycle time |

|

Mould life |

300,000---3000,000 shots |

Delivery Time |

45~90 days |

Why choose Yisen mould as your suppiler:

Pre-production proposal |

We offer professional & practical solution for your investment |

Mould process report |

Weekly report, mould trial video and samples for your checking |

Mould design approval |

2D/3D mould drawing & mould manufacturing schedule for customer's approval |

Quality Written warranty |

Steel cetificate, mould trial report, parts measuring report, operating instructions, maintenance specifications |

Spare parts |

wearing spare parts provided |

After service support |

Provided |

Communications |

Email, phone, Trade Manager, Msn, Skype, yahoo |

Advantage |

Skilled Language to ensure good communion |

Special in exported mould,experienced in international standard |

Rational mould design to extend mould life,and to get high production efficiency, |

Precision Machining to fine parting line effect |

Welcome send your detial information

| Prod Model: |

YS006 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Size: |

240L |

| Shaping Mode: |

Injection Mould |

| Application: |

Commodity |

| Installation: |

Fixed |

| Process Combination Type: |

Single-Process Mode |

Yisen Mould Profile:

Yisen Mold is a privately-owned enterprise specializing in manufacturing plastic injection moulds. We have many advanced professionals who can make 3D designing and technical drawings with CAD/CAM/CAE according to our customers' requirements.

Yisen Equipment:

There is a wide variety of sophisticated equipment imported from abroad such as 3-coordinate measurer, NC imitating milling machine, large precision EDM, high-speed milling machines, injection machine, spot machine, wiring machine and so on.

Scope of mold make services:

Injection molds for daily used goods, Injection molds for industrial goods, Injection molds for baby goods.

The former includes plastic furniture series, tableware sets, Sanitary ware series, warm-keeping boxes, and laundry boxes.

The latter is composed of shower parts, piping, stationery, car safety bars, meter panels, door plates, steering wheel and mudguard etc.

Injection molds for baby goods include baby chair.

Our Manager: "USERS THE FIRST, CUSTOMER THE PARAMOUNTCY", once the contract is signed, we will fulfill the terms and conditions and strengthen after-sale service and release all the worries from our customers.

Our after-Service: Is your full-service partner of small to large products utilizing up-front engineering support, superior customer services, and state of the art process control techniques. Whole solution from product design, mold design, mold making, rapid prototype, precise injection molding to secondary processing; From idea to product, Hongsen PM is a good answer in China.

Our Mission:

Our mission is to provide the mostservices and products that meet or exceed our customer needs and expectation, in terms of high quality, consistent reliability, on time delivery and reasonable price.

Our Capabilities:

Engineering / Technical, Product Design, Mold Design, Reverse Engineering, Mold Flow Analysis, Project Management.

Mold Build:

Molds up to 1.5 meter and up to 15 tons weight. Hot-runner Capability. Gas-assisted Capability. Double-colored Capability.

Injection Molding:

80 Through 800 Ton Injection Molding Presses. Robotic and Automated Pick and Place. Gas Counter Pressure.

Secondary Operations:

CNC Machining, Oil spraying, Silkscreen printing, Pad printing, Hot stamping, Ultrasonic welding, Bronzing, Solvent Bonding.