Basic Info.

Model No.: SMI0004

Shaping Mode: Injection Mould

Export Markets: Global

Additional Info.

Packing: Standard Export Wooden Box

Standard: As Per Customers Requirement

Origin: China

HS Code: 8480710090

Production Capacity: 60 sets/Month

Product Description

Plastic Injection Mold

1. Mould steel: Steel 45#, 50#, 718, 2083, P20, NAK80, etc.

2. Plastic Material: ABS, PP, PE or as per customer requirement

3. Mould life: 500, 000 shots or as per customer requirement

4. Product Size: As per customer requirement

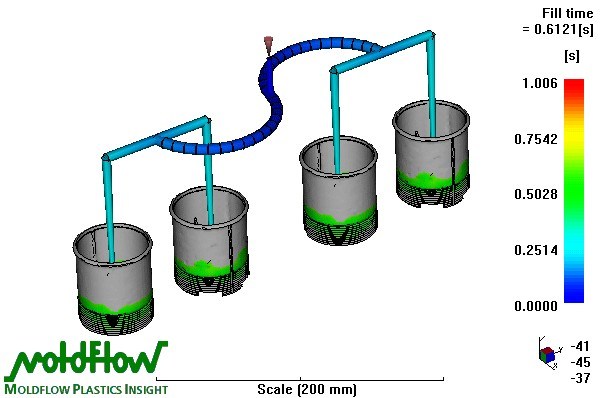

5. Runner: Hot/cold

6. Cavity: Single/multi

7. Design software: UG, PROE, PROWERMILL, CAD, CAXA ect

8. Advanced CNC machining centers, EDM machine, wiring machine, grinding machines, lathes, drilling, injection molding machines, and other large and medium-sized imported equipment alike.

Manufacturing Processes:

Step 1: Mapping and Surveying

Step 2: 2D&3D date drawing

Step 3: Machining( CNC, Drilling, Milling, EDM, WDEM, Engraving and Die Spotting)

Step 4: Assembly

Step 5: Mold Trial

Step 6: Mold Modification

We have a lot of experience in making plastic mould(injection mould), such as auto part mould, household appliance mould, ATV mould, daily necessity mould, turnover box mould, plastic crate mould, plastic pallet mould, and we can also manufacture finished product.

Steel Grade Characteristics Applications

S 136 High purity, high polishability to mirror finish, with good corrosion resistance and low distortion after heat treatment. High quality mould insets with mirror suface finish and good corrosion resistance, best suitable for plastic moulding of PVC, PP, PE, PC, machine parts for food processing machinery.

NAK 80 High hardness, good polishability, exellent photo etchingablity, good EDM machining and weldability Moulds require high wear resistance and exellent surface finishing.

718H High purity High quality mould inserts, best suitable for moulding of PS, PE, PP, ABS.

2316 High corrosion resistance High corrosion resistance moulds with good polishability

P20 Good polishability Suitalble for moulds require good surface polishing

2312 Exellent machinability Plastic mould for general use and core parts

SAIMING International is a professional mechanical manufacturer with factory in Gong Ming Shenzhen which was set up in 2004, with years of continuous investment and improvement, now grows into a "One-Stop" manufacturing center cover 20, 000 m2; 4 separate buildings with highly skilled workforce of 600 people, 40 of them are engineers, 6 of which are senior engineers with more than 10 years' experience. The services offered include:

Product Design advice and Prototyping

Mold Making

Aluminum and Zinc Alloy Die Casting

CNC Machining, CNC turning, CNC milling

Surface Treatment

Plastic Injection Molding

Aluminum Extrusion

Complete sub-assembly

SAIMING provides our customers more than good quality, on time delivery, competitive price. We exceed our customers' expectations by suggesting the ideal solution prior to the commencement of production, with the aid of cost analysis and value engineering process; By providing project management to ensure the sample and production schedule can be met; By offering integrated manufacturing service to easy our customers' supply chain work.

Now our manufacturing services cover the complete spectrum of manufacturing industry, including Green Energy, Medical Equipment, Telecommunication, Household Appliance, Military, Lighting, Hydraulics, Building, etc.

We appreciate all our clients who have supported SAIMING and our employees who have dedicated themselves to SAIMING.