We are a mould factory located in Huangyan district Zhejiang province--the hometown

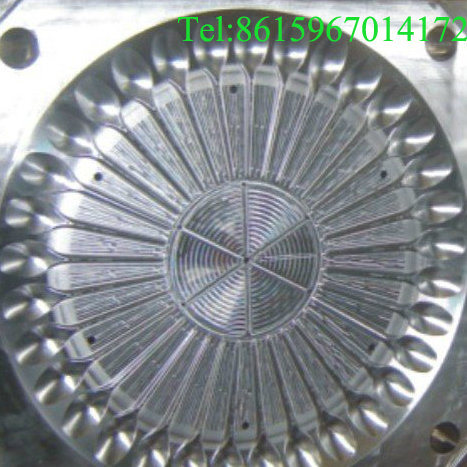

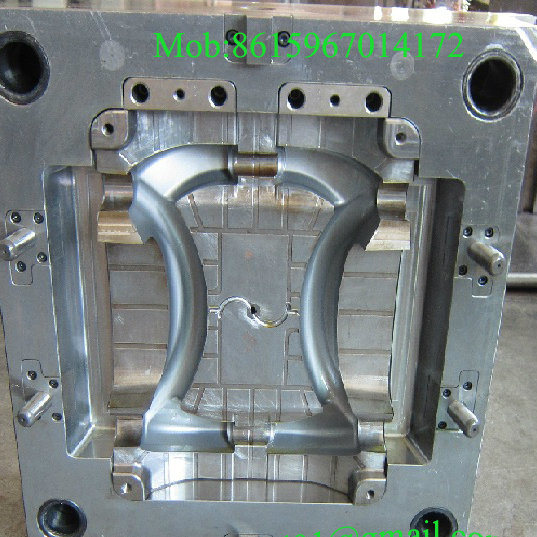

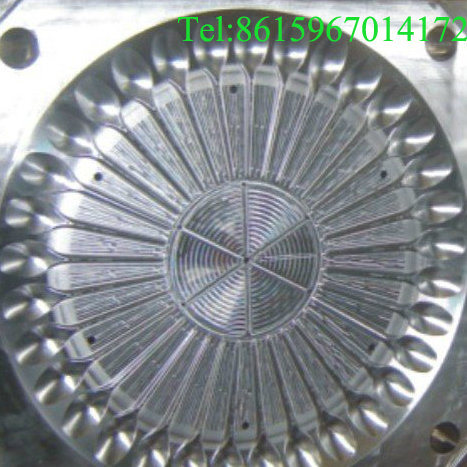

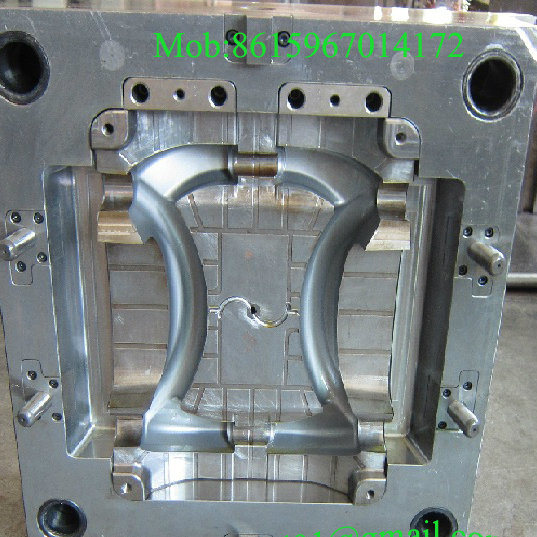

of the mould in China,We specialize in plastic injection mould,household injection mould,home appliance mould,basket mould,pallet mould,crate mould,preform mould,cap mould and blowing mould,and so on

with modern technology and advanced equipments.For over 15 years diligent operation,we

had established a mature one-stop service line from inquiry to after-sales service.

Our mould features:

| 1.· Mold cavity from 1 to 48. |

| 2.· Adopt imported high-quality mold steel(# P20 steel and #2316 Steel Germany,#718,#s136 and so on). |

| 3.· Adopt advanced hot runner system with point to point control system,which ensures uniform heating. |

| 4.· Each core and cavity adopt independented cooling system, which brings high productivity. |

| 5.· Mold cavity is replaceable,which is convenient to change the label. |

| 6.· At least 3 million shots life-time guaranteed. |

| 7.· Electric control system with simulating stretch testing to improve yield rate. |

| 8.· The materials of core and cavity are made of mirror corrosion resistance and plastic mold steel imported from Sweden or Germany. |

| 9.· International standard screw neck, imported nitrided steel with high hardness and long life time. |

| 10.· Adopt advanced hot runner system with point to point control system,ensure uniform heating,which brings high-quality products. |

| 11.· Valves gate mold without tail,reduce the labor force. |

| 12.· Spare parts are processed by CNC,which ensure the precision. |

| 13.· Adopt advanced technique to make each cavity self-lock,and ensure mold concentricity(tolerance less than 0.08mm). |

| 14.· Design different kinds of mold structure,such as Long Tail Mold, Short Tail Mold,Pneumatic Valve Mold,etc. |

| 15.·Great final polish |

Why choose us:

1.We have more than15 years experience designers.They will give you good advice on mould materials,mould structure,materials input way according to your product requirement.

2.You just provide us drawings or samples,then you will see the mould shape made by software in a short time.

Our first-rate machine can ensure you high precise.Our factory own advanced equipment,such as CNC,EDM,wire-cutting,milling machine,grinding machine,lathe,etc.

3.Our boss who has decision-making power is also a engineer,so you can communicate with him about mould price and mould structure.

4.Our moulds have been exported to USA,Europe,Middle East.All services received highly commended.

We would like to quote you according to any inquiry.Waiting for your inquiry all the time.

Taizhou Huangyan Xing Xi Te mould factory located in Huangyan district Zhejiang province--the hometown of the mould in China, specializing in PET preform mould, PP preform mould, PET preform mould with valve gate, PET preform mould with short tail, PET preform mould with long tail, mineral bottle preform mould, beverage bottle preform mould, edible oil bottle preoform mould, engine oil bottle preform mould, 3 gallon preform mould, 5 gallon preform mould, preform mould with different weight, preform mould with different length, preform mould with 1 to 96 cavities, cap mould, injection mould, water bottle mould, mineral bottle mould, shampoo and costmetic bottle mould, fruit juice bottle mould, oil bottle mould, jar mould, barrel mould and so on with modern technology and advanced equipments. For over 15 years diligent operation, we had established a mature one-stop service line from inquiry to after-sales service.

Xing Xi Te Mould uses the latest versions of PRO-E, U. G, Solid-work, auto-CAD to designfull 3D formats and uses the Mold-flow for the analysis of injection. With rich experience in designing, the design team has the ability to provide the financially feasible solutions to meet all the requirements of clients.

Our target is to be your business partner and provide you with complete solutions in high quality and compatible prices. Our founders' experience in mold design, mold manufacturing and injection molding process makes us a strong and reliable partner for you.

We do believe that only good quality molds with compatible prices would lead long term win-win cooperation.