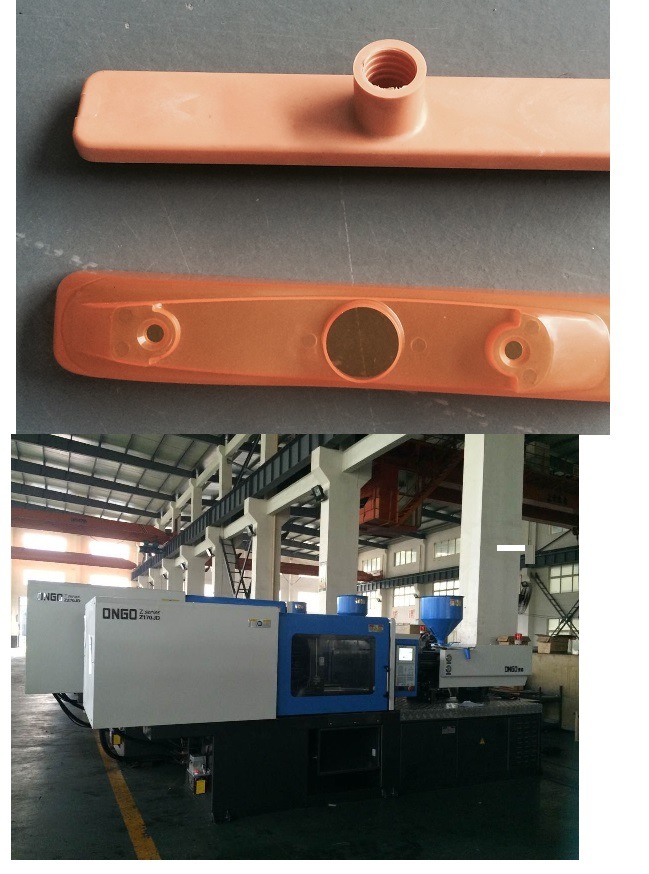

Plastic Injection Machine for Broom Base

| Price: |

US $ 1/Set |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,Money Gram,Western Union |

| item | Z270 |

| injection unit |

| A | B | C |

| screw diameter | mm | 50 | 55 | 60 |

| shot volume(theoretical) | cm3 | 530 | 641 | 763 |

| injection weight(ps) | g | 482 | 583 | 694 |

| injection rate | g/s | 187 | 227 | 270 |

| injection pressure | Mpa | 205 | 169 | 142 |

| screw speed | rpm | 180 |

| clamping unit |

|

|

| clamping force | kN | 2700 |

| open stroke | mm | 540 |

| space between tie bars(WxH) | mm | 570x570 |

| max mould height | mm | 550 |

| min mould height | mm | 200 |

| ejector stroke | mm | 150 |

| ejector force | kN | 70 |

| others |

|

|

| max pump pressure | Mpa | 16 |

| pump motor power | kW | 22 |

| heating power | kW | 16.8 |

| machine dimension(LxWxH) | m | 5.90x1.60x2.25 |

| oiltank cubage | l | 380 |

| machine weight | t | 8 |

- The energy saving electromagntic heating system

- Linking connecting rod

- Platen center is thick enough----New utility model patent:200920121070.7

- Enhanced stationary platen------New utility model patent:200920122627.9

- Special customized optimized control system------Design patent:200930142016.6

- Injection preplastication seat with oil copper sleeve

- Colsed base structure

- Automatic mould adjustment

- Sealed structure with cone surface

- Sppray plastic in oil tank----New utility model patent:200920121071.1

- Double moveble hydraulic cyliders tighening structure

- Copper bush with hgih quality

- Number conersion linkage stucture

- The device to transit thin lubrication oil in colume style

- Screw rotational speed detection

- The energy saving electromagntic heating system

- Linking connecting rod

- Platen center is thick enough----New utility model patent:200920121070.7

- Enhanced stationary platen------New utility model patent:200920122627.9

- Special customized optimized control system------Design patent:200930142016.6

- Injection preplastication seat with oil copper sleeve

- Colsed base structure

- Automatic mould adjustment

- Sealed structure with cone surface

- Sppray plastic in oil tank----New utility model patent:200920121071.1

- Double moveble hydraulic cyliders tighening structure

- Copper bush with hgih quality

- Number conersion linkage stucture

- The device to transit thin lubrication oil in colume style

- Screw rotational speed detection

- The energy saving electromagntic heating system

- Linking connecting rod

- Platen center is thick enough----New utility model patent:200920121070.7

- Enhanced stationary platen------New utility model patent:200920122627.9

- Special customized optimized control system------Design patent:200930142016.6

- Injection preplastication seat with oil copper sleeve

- Colsed base structure

- Automatic mould adjustment

- Sealed structure with cone surface

- Sppray plastic in oil tank----New utility model patent:200920121071.1

- Double moveble hydraulic cyliders tighening structure

- Copper bush with hgih quality

- Number conersion linkage stucture

- The device to transit thin lubrication oil in colume style

- Screw rotational speed detection

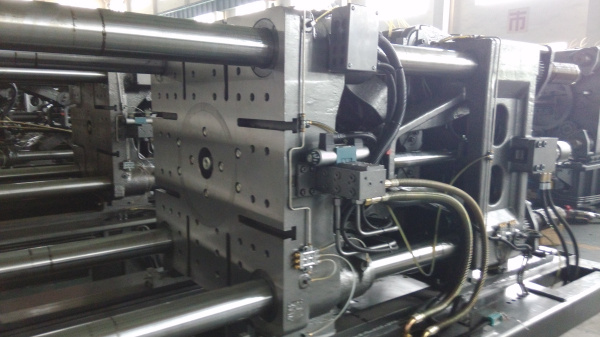

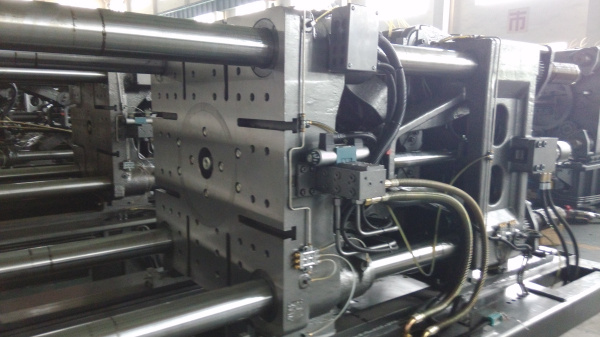

3.injection molding machine pictures

| Prod Model: |

Z270 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Clamping Force: |

2700kn |

| Type: |

Tube Shoulder Injection |

| Structure: |

Horizontal |

| Plastic Type: |

Thermoplastic |

| Plasticizing Way: |

Screw Type |

| Clamping Way: |

Hydraulic |

| Automation: |

Automatic |

| Computerized: |

Non-Computerized |

| Certification: |

ISO9001:2008 |

The precursor of "ONGO" was established in 1992. After more than 20 years running, we have formed a professional team with more than 10 years developing and manufacturing experience in high-grade plastic injection machine. We adpot morden development technology and scientific management system to build "ONGO" Z series high-grade plastic injection molding machine FROM 700KN to 30000KN clamping force.

The company is situated in Ningbo Industrial Electomechanical Park, covering an area of more than 60000 square meters with an annual output of some 3000 sets.

"The profession guarantees quality, the technology Creates future". Depending on up-to-date technology, strong productivity, scientific management and customer-oriented concept, the company has been one of the most active enterprises in plastic machine industry in China!