Product Description

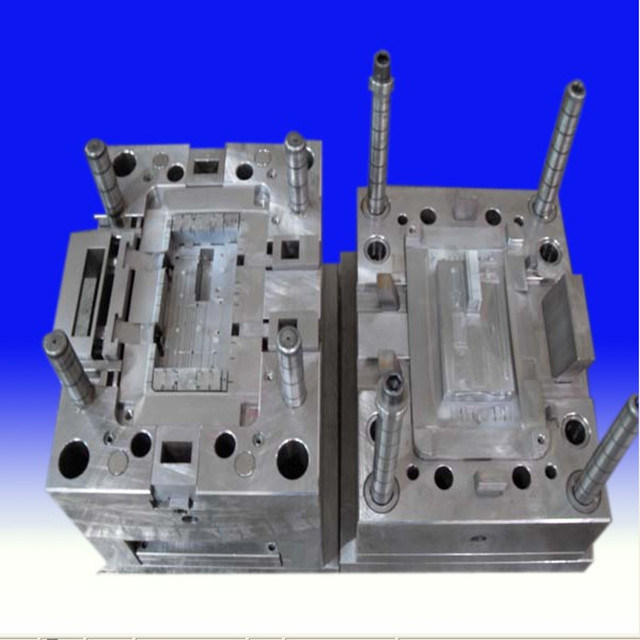

1. Basic Properties

1). Material: NAK80, S136, P20 SO ON, ABS PE PC PVC

2). Standard: HASCO,STACK,DME,PCS..

3).delivery time :30days

4)ISO9001:2000 OEM&ODM

2. Production Process

1). Clients offer 3D drawings in format of igs,prt, stp or CAD drawing, and sufficient information of plastic parts.

2). We offer the quote of injection mold and plastic parts in half a day.

3). Clients consider the quotations.

4). Clients place the order

5). We design and manufacture the injection mould after confirming the drawings and detailed information with clients again.

6). Send plastic mold trial samples to clients to get their confirm and to see if there is any modification before mass producton.

7). Arrange mass production at once and finish the production before the leadtime.

3. Product Feature

Overloading protector ,lightning protect , USB ,this function can be choice as your prefer

4. Application

Extensively used in household products, electronic industry and so on.

5. Attentions

1)The total power connected to the electrical appliance can't be higher than the rated power.

2)Forbid to bind the wire together strictly when using so as to avoid abnormally overheat.

3)Please insert the plug into the jack absolutely.

4)Please place it on where the children can't reach.

5)Please don't use it in damp environment.

6)Please don't remove the top cover presumptuously, contact with us if need service.

6. Our advantages

1). Precision Own Mold-Making Technology (Since 1998)

2). Competitive Price: Origin Manufacturer.

a. Mold-Making Plant

b. Silicone Rubber Compression Plant

c. Plastic Injection Plant

d. Liquid Silicone Rubber Injecton Plant (LSR)

e. Assembly Plant.

3). Five Experienced Designers and Engineers

4). Production and Test strictly according to ISO9001.

Test Equipment: 3D Projectors, Sealing Testor, Elasticity Measurement, Durometer, etc.

5). Production Environment

6). Rapid Reaction Organization: Support Customer at short time

Mould Base | Hasco and Standards |

|

| Mould Steel | LKM | LKM2083 LKM2316A lKM2344 LKM818H LKM838H LKM738H LKM2311 |

| ASSAB(Sweden) | ORVAR8407 IMPAX718S IMPAX718HH PX88 STAVAX S136 STAVAX S136H |

| DAIDO(Japan) | NAK55 NAK80 DC11 DC53 |

| FINKL(America) | P20HH |

| SAARSTAHL(Germany) | GS2344 |

| (Germany) | 1.2344 1.2343 |

| Hot Runner | BUDERS(Germany) | 1.2344 1.2344 |

| Standard Parts | MOULD MASTER,HUSKY, HASCO DME,THERMOPLAY YUDO SYNVENTIVE |

|

| HASCO,DME,MISUMI NEAREST DIN STANDARO LKM |

|

Five production plants:

1.Mold Tools Making Plants

2.Rubber (Silicone) Plants

3.Plastic Injection Plants

4.Liquid Silicone Rubber Plants (Dust-free)

5.Assembly Plant(Dust-free)

Xiamen Better Silicone Imp/Exp Co., Ltd, as a united corporation, which specialize in producing silicone/rubber/plastic/LSR (liquid silicone rubber) parts and mold tools.

Four Production Plants:

1. Mold-Making Plant;

2. Silicone Rubber Plant;

3. Plastic Injection Plant;

4. LSR Injection Plant.

As a factory managerment cooperation, we focus on improving each factory production efficiency and take full advantage to enjoy customer's demands and meet marketing demand.

Aim to improve make-making technology, company try best to bring in better technologies, talents ect.

Dispensable Fast Reaction: Mold-making, Silicone/rubber/plastic/LSR Plants, experienced technical perons, and managerment system etc.

We have strong team in research field. Any kinds of pattern mould can be developed according to the customer requirement, therefore, many kinds of eco-friendly, high quality silicone products to be showed to the customer. Our silicone raw material brands are Dow Corning, Shin-Etsu, Toshiba, KCC, etc, using these material to provide our customer various of medical and daily commoditties, such as silicone resuscitator parts, silicone kitchen parts, silicone promotion gifts, silicone rubber seal/gasket, silicone auto parts, silicone cell phone parts, silicone shower head, silicone baby goods.

Basing on abound experience, down-to-earth working attitude, innovative spirit and consummative management system, all products can achieved SGS, FDA, ISO9001: 2008 quality managing system certification.

For better quality and service is our motive force source.