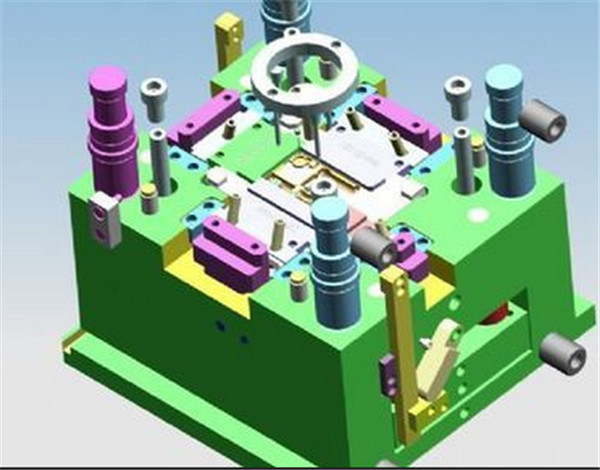

plastic injection mould spare parts for plastic goods

Household Appliances, Commodity, Electronic, HomeUse Professional ODM/OEM Plastic Injection Mold

1. Basic Information

Mold type: All tyes of produts plastic mould

Mould base material: #45. LKM, LYM standard etc

Mould spare parts material: Jinghong, HASCO, DME etc

Hardness of steel: 28-50HRC

Mould design: 3D/2D drawings

Runner: Cold runner

Design days: 1-3days

Mould life: 500, 000-3, 000, 000 shots

Plastic material: PE, PC, PS, PP, PA, ABS, etc

Injection system: Pin point gate

2. Customers assistance for initial detailed quotation on plastic injection molding

1) 2D/3D Design drawings offered

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material information

4) Level and quantity information if possible.

| Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard, etc |

| Mould base | LKM&Hasco&DME standard (A,B plate 1730,2311,2312,P20 ), etc |

| Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13, etc |

| Hardness of steel | 46~56HRC |

| Material for Slider ,Lifter and all sub insert use | 1.2767 HRC |

| Cavity | Single-cavity ,Multi-cavity |

| A surface request: | EDM & High Polish |

| Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

| Mould life time | 500000~+3,000,000 shots |

| Quality | ISO9001:2008,SGS |

| Product material | PA,PA6/6+GF,ABS,POM,PC,PP,PET,TPE,PVC,HDPE etc |

| Export country | Japan, Europe,USA,Mexico,Australia ,Middle-east ,Asia etc |

| Value-added service | Polish,texture,painting,screen printing,turnkey project |

Mould Steel:

ASSAB (Sweden), DAIDO (Japan), A. FINKL (America), GS (Germany), LKM (China) or Other Imported Steel.

Mold Base: DME, HASCO, FUTABA, LKM, Minglee or equivalent.

Hot Runner: EWIKON, MOLD MASTER, SYNVENTIVE, HUSKY, HASCO, DME, YUDO, INCOE, HOTTIP, MasterTIP etc.

Longeron mold Co; Ltd. Optimization the mold flow system with our hot runner supplier and they have global guarantee.

Standard Parts: DME, HASCO, PARKER, STAUBLI, RABOURDIN, DAIDO, PROGRESSIVE, LKM etc.

Mold Construction details

1)Mold cost . There are several known procedures for caculating the economical number of cavities. Unfortunately they are so varied that it is impossible to condense them .

Efficient production of the most diverse injection-mold parts depends primarily on the injection mold . The durability od the molds depends on their care and treatment .Since the moving components and the cavity of the mold are always hardened and ground, they should produce between 500,000 and 1000,000,000 shots .

Basic Mold Construction Operating Principle

Basically the injection mold consists of two halves. One mold half contains the sprue bushing and runner system, the other half houses the ejection system. The molded part is located at the parting line .

2) Single or multicavity Molds

To set up a calculation conceiving the choice of cavities in an injection mold requires accurate knowledge of the material to be processed ,of the injection-molding machine and of the molds. The mold costs increase with the rising number of cavities and the relative machine costs decrease.

3) The production time required for a given molded part depends on the wall thickness, the injection speed, the recovery rate, the time required to cool the molded material, the cooling capacity of the mold and the necessary incidental time such as duration of presure holding time ,ejection time,delay time, etc.

4) Therefore the decision concerning the number of cavities to be determined depends on :

1). Size of order ( number of molded parts in connection with delivery time);

2).shape of the molded parts (size,quality requirements)

| Supplier Company Name | Dongguan Longeron-mold Technology Co;Ltd. |

| Made-in-China Supplier Member ID | Longeron-mold |

| Company Address | No.5 Qingzhang road(next to Qingxi bus station),Qingxitown Dongguan City,Guangdong province,China. |

| Contact Person | Susie Xu |

| Mobile Number | 86-18923633826 |

| Telephone Number | 86-769-87366628 |

| Website | Http://longeron-mold.en.made-in-China.com www.longeron-mold.com |

"Longeron"Co., Ltd. is specialized in all kinds of plastic injection moulds which is including Automotive parts mold(Mainly for car decorated mould, auto doors accessories injection mould, Auto ventilation tube injection. ), home appliance mould( mainly for TV plastic injections mold). At the meantime, We also have rich experience in medical, aerospace injection mold manufacturing.

Complex mold, precision mold is our strengths!

We' re pleased to get your Inquiry and we will come back to as soon as possible.

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

To perfect our service, we provide the products with good quality at the reasonable price.

1. Showing you a "ONE STOP" service to you.

2. Our goal is to help you develop and produce your new project, and we will try best to reduce cost AS LESS AS POSSIBLE. We have 80% product are export to Europe and USA, and cooperation is very happy, hope we can servicing to you also. Please kindly review and contact me.

Advantages:

1. We are the manufacturer, our own mould factory, so we have competitive price.

2. Continuous service as support.

3. Diversified rich experiences skillful workers /Speicialized Designer.

4. Custom R&D program, coordination.

5. Long Life cycle and high quality.

6. One-stop service.

7. Complex mold, precision mold is our strengths!