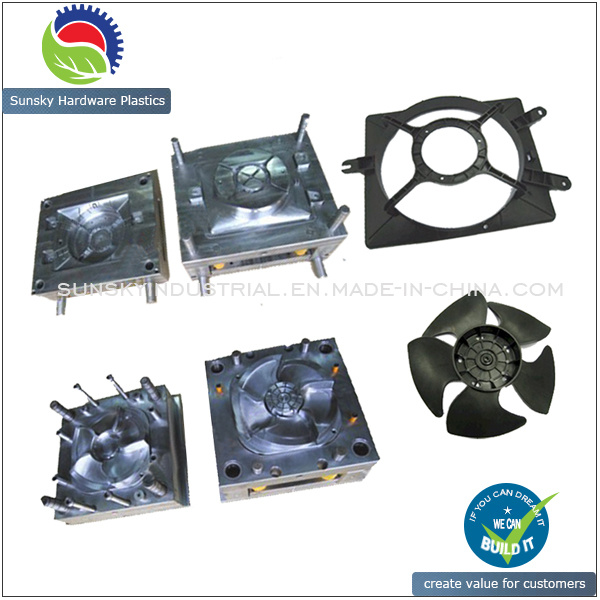

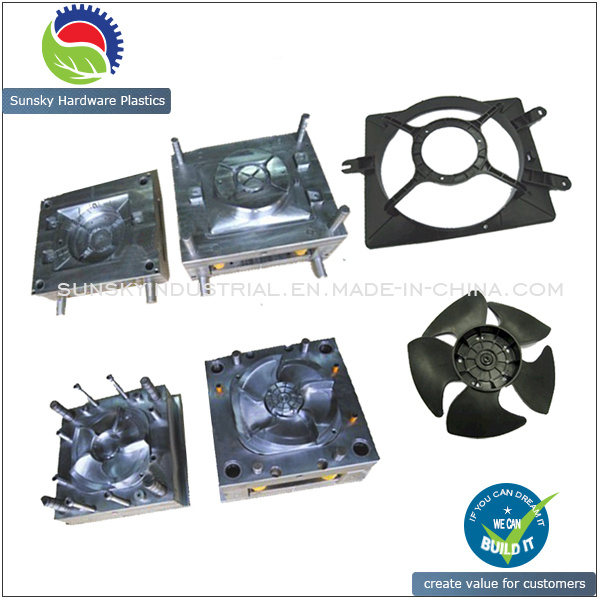

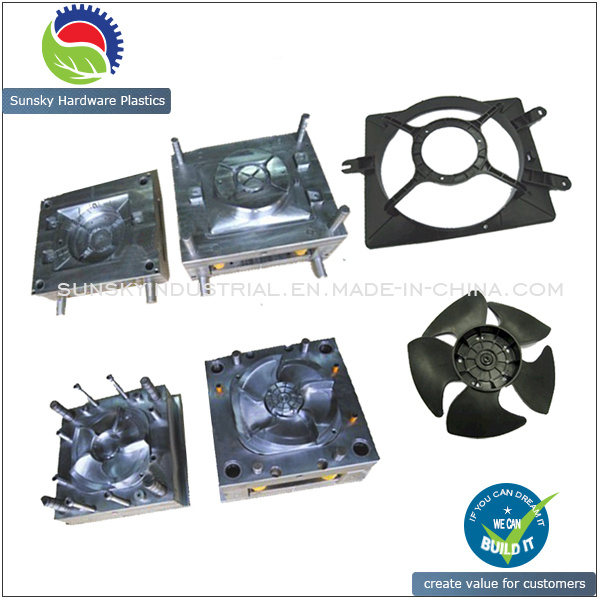

SUNSKY Injection Plastic Radiator Fan Mould / Exhaust Fan Mould / Auto Fan Mould Making Plastic Injection Molding , Home Appliance Mold , Auto Parts Moulding , Plastic Injection Mould , Plastic Injection,injection mold, Injection Plastic, Radiator Fan Mould, Exhaust Fan Mould,Auto Fan Mould Making1) Mould design: Mold design according to your product drawing or sample.

2) Steel material: P20, 718, NAK80, S136, SKD11, 8407, 1.2363 or customers' appointed material.

3) Mould type: Plastic mold, hot runner mold, double injection mold, insert mold, rubber mold, die casting mold, stamping mold.

4) Mould processing: Using advanced equipment for the molds, including digital control CNC (computer manufacturing center), EDM (electric-spark machine), several line cutting machines, multi-function milling machines etc

Advantages:

1. Competitive price

2. Strict quality control system

3. Quick mold making and delivery

4. Advanced equipment, excellent R&D teams

5. Professional technicians and rich experienced workers

Sunsky has designed and built the Chinese plastic radiator.

Sunsky has designed and built the Chinese plastic radiator.

With the collaboration of BASF we produced the first plastic radiator 5 years ago. Our technical knowledge in application of high heat, hydrolysis resistant materials. coupled with specialised tool for this application has won us many customers. We build products that will meet HASCO DME standard.Description of SUNSKY Plastic Injection Fan Mould |

Mould material | 45#, P20, H13, 718, 2738, NAK80, S136, CENA-1 etc. |

Mould base | LKM, HASCO etc. |

Standard Component | DME, HASCO, JIS etc. |

Cavity | single/multi |

Runner | hot/cold |

Mould life | 50,0000-1,000,000shots |

Design software | UG, PROE, CAD, SolidWorks etc. |

Plastic material | PP, PC, PE, PS, PU, ABS, PVC, PA, POM, PMMA, PET, PPR etc. |

Delivery time | 45--60days |

Package | Wooden Case |

Delivery | By Sea |

Specifications | Depends on customer's requirements |

Process Machine | CNC, High Speed Carve, EDM, Wire Cut, Driller, Grinder, fly cutter etc. |

Sunsky Hardware Plastics is a manufacturer of machined, molded and fabricated components with expertise. We specialize in six main categories of the manufacturing industry, Aluminium/Zinc Casting, CNC Machining/Turning, Injection Molding, Mold design/fabrication, Rapid Prototype and Value-added service.

• Located in Dongguan and serving the local market place since 2007.

• In-house mechanical engineering departments

• Design and fabrication of all parts are done in-house

Our parts are widely used in the market as diverse as Electronics, Medical, Industrial, Defense, Transportation and Consumer.

We pride ourselves on working closely with our clients to ensure you get exactly what you need.

Browse around our website for more information, or contact us if you have any questions.

Customers come to Sunsky for our best global costs. But they count on us for these three main advantages.

Process Specialists: Our factory started with Plastic Molding first. We know the art and science of multi component molding. And we run all kinds of resins from stiff Acetel and Glass-Filled Nylon to styrene and olefins. Our dual injection processes can help the look, the cost and the reliability of your designs. That makes your profits greater.

True Global Support: Our seasoned team works throughout the US so you can draw on their experience with top-tier manufacturers. Our Hong Kong administrative team handles reporting and logistics. Our China team handles CAD, manufacturing plans, production and testing. Combined, you get the kind of people who understand molding, launch phase and sustained project management. That makes your job easier.

Quality: We know how to make your molding look great. Sure we are ISO certified, we have proven capability and customer awards. But more than that, exceptional molding comes from combining deep experience with the culture of a cosmetic molder. You can see it in the color breaks, the bright chrome plating and the details of in-mold-labeling and remarkable surface finish. That makes your products better

And There Is More: Molding With More. More dual injection. More product decoration. More packaging and final pack. More ways to complete the work that starts with molding and ends with more sales of your products.