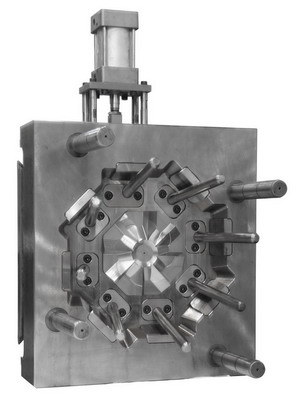

OEM Plastic/rubber extrusion/blowing/injection mold/ moulding for medical/auto parts

Product description:

Die casting mould/ plastic injection mould/coompound mould/progressive mould supplier

-Product Name: Plastic Mold/mould

-Mold Steel: NAK80

-Sample Material: ABS + PC

-Cavity: 1 x 1

Specifications:

Yonwoo is a modern and high-tech plastic injection mould factory. The factory equipped with CNC advanced machining center, EDM machine and so on.

1. We are a professional plastic mold and injection moulding parts manufacturer, OEM is available as according to the customers' drawings.

2. Our main products include precision mold manufacture, plastic products, silicon products, Parts for automotive, consumer product etc.

3. High quality, close tolerance plastic parts production.

4. Good surface treatment, strict international tolerance standard.

5. Welcome to your drawings (such as 2D and 3D) or samples for quoting.

Advantage:

1. Competitive price.

2. Continuance service and support.

3. Diversified rich experienced skilled workers.

4. Custom R&D program coordination

5. Application expertise.

6. Quality, reliability and long product life.

Engineering capabilities include:

1. Parts design.

2. R&D products.

3. Prototype design and production assembly.

4. Reputable design software used for all design work.

5. Hot runner design.

6. Cold runner design.

7. Mold design with a team of experienced specialists.

We can make your vision a reality. Please contact us without hesitation, coorperate with us is your best choice, believe me.

STEPS

1. Negotiations: Quality, material, price, payment, delivery time item and so on.

2. Place an order: According customers drawing or sample.

|

Mould Material: |

718.718H, NAK80, S136, 2311, 2344, 8407, 2083, P20 |

|

Core Steel: |

718.718H, NAK80, S136, 2311, 2344, 8407, 2083, P20 |

|

Cavity Multi |

Single cavity, Multi Cavity |

|

Shot Runner: |

Cold or Hot Runner_ HASCO/DME/YUDO etc. |

|

Mould Base: |

LKM, FUTA, HASCO, DME, etc. |

|

Main Cavity/Core Material: |

ASSAB from Sweden/DAIDO from Japan/AUBERT&DUVAL France etc. |

|

Mould Life: |

300,000 to 500,000 shots |

|

Specification: |

According to customers’ requirement |

|

Design & Program Soft wares: |

CAD/CAM/CAE, UG, Proe, Powemill, Solid works etc. |

|

Equipments: |

CNC, EDM, Haitian & DEMAG / FCSPlastic Injection Machines |

|

Package: |

Wooden casepacking or OEM packing |

|

Mold building lead time: |

2-4 weeks |

Hovesin (DG)Industrial Co., Ltd is a wholly-owned subsidiary of Wellsmart(HK)industrial international Co., Ltd. And it's established in Chang'An town of Dongguan since 2002. It occupies 5000 square meters, with about 150 employees. Through more than 10 years of rapid delelopment, our company is an OEM & ODM integrated enterprises, including product R&D, mould development, plastic injection, die casting, stamping, sheet metal, precision hardware, CNC machining, assembly, etc. The main products is auto parts, medical parts, electronic parts, communication parts, lighting parts, display parts, daily use parts, tail-lift parts, etc. Primarily for plastic mould& parts, die casting mould& parts, stamping mould& parts.

Based on more than 10 years of development, supported by saling, R&D, mould and parts, through integration of precision injection, die casting, hardware, assembly, we always supply integrated solutions for customers. Our company has capability of large mould machining, large parts forming. There are 2meters of large CNC machining center in tooling house; 600 tons of plastic injection equipments in injection dept.; Most advanced die casting equipments(Yizumi )in die casting dept.; Large laser cutting, CNC Bending Machine, CNC lather in hardware dept.; And 3 automatic assemble line in assembly dept.

In future 10 years, we will further fortify the development of precision mould, precision injection, exquisite hardware, and make further effort to meet customers' requirements, to improve compositive service of our company.

Our customers come from England, USA, Holland, German, Sweden, Canada, Russia, Australia, New Zealand, Unraine, India, Brazil, Janpan, South Korea, Turkey, Egypt, South Africa, etc.

Our company strictly implement of ISO9001: 2010 international quality management system. There are fefect test equipments, such as KSY, Projector, and other measure equipments; Meanwhile, there are anti-ultraviolet test machine, Salt Spray test machine, etc.