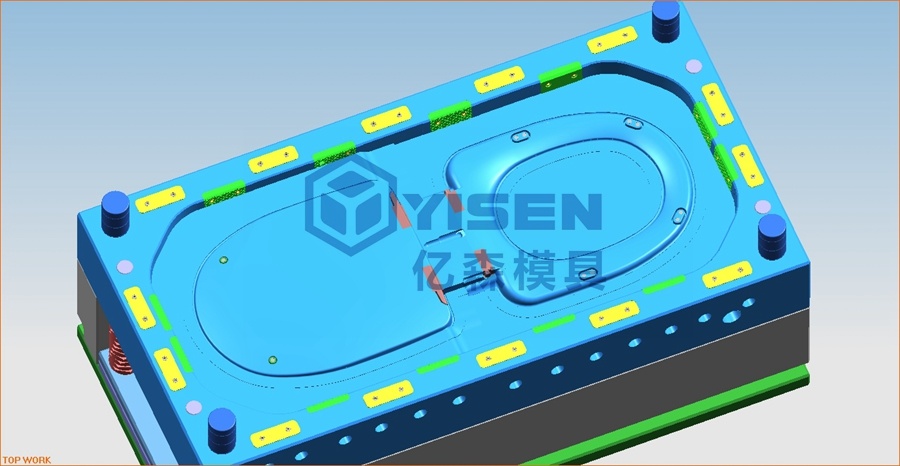

Plastic PP Toilet Seat Injection Moulds

| Price: |

US $ 10000-15000/Piece |

| Trade Terms: |

FOB,CFR,CIF |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

We are professional in designing and manufacturing toilet seat moulds.

YISEN MOULD Co.,Ltd is specialised in making different kinds of plastic injection moulds for more than 10 years, we can rich experiences. Our company is very strict on moulds quality, our main customers are from France, Germany, Italy, Australia, Brasil, etc.

We not only can help you manufacture toilet seat injection moulds, but also can help you make mass production if you have no injection molding machine in your company.

Contact with me, we can offer you one-stop solution, plastic material, moulds, injection machines, mass production, etc.

| Product Name | Plastic PP toilet seat injection mould |

| Product material | PP |

| Core& Cavity Steel | P20,718H,DIN1.2311,DIN1.2738, DIN1.2344 according customer's requirement |

| Mould Standard | DME, HASCO |

| Cavity Number | 1-cavity, 1+1 cavity, multi-cavity |

| Injection System | hot sprue |

| Ejector System | Ejector Pin |

| Cycle Time | 45 second/shot |

| Tooling lead time | 45 days |

| Mould life | differs from different moulds steels |

| Quality assurance | ISO9001, CE |

| Our Advantage | 1. Reasonable price |

| 2. Good product & mould design |

| 3. Good mould tooling and good mould steel |

| 4. strict quality control |

| 5. On time delivery |

6. Good After-sales services

|

Welcome your enquiry from us.

Contact person: Lily Lin

| Prod Model: |

YISEN model 048 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Mould Cavity & Core Steel: |

718h; DIN1.2344 |

| Mould Cavity Number: |

Multi-Cavity, 1+1 Family Mould |

| Toilet Seat Plastic Material: |

PP |

| Hot Runner Brand: |

Yudo, Incoe |

| Shaping Mode: |

Injection Mould |

| Application: |

Home Use |

| Installation: |

Mobile |

| Process Combination Type: |

Single-Process Mode |

| Plastic Material: |

PP |

Yisen Mould Profile:

Yisen Mold is a privately-owned enterprise specializing in manufacturing plastic injection moulds. We have many advanced professionals who can make 3D designing and technical drawings with CAD/CAM/CAE according to our customers' requirements.

Yisen Equipment:

There is a wide variety of sophisticated equipment imported from abroad such as 3-coordinate measurer, NC imitating milling machine, large precision EDM, high-speed milling machines, injection machine, spot machine, wiring machine and so on.

Scope of mold make services:

Injection molds for daily used goods, Injection molds for industrial goods, Injection molds for baby goods.

The former includes plastic furniture series, tableware sets, Sanitary ware series, warm-keeping boxes, and laundry boxes.

The latter is composed of shower parts, piping, stationery, car safety bars, meter panels, door plates, steering wheel and mudguard etc.

Injection molds for baby goods include baby chair.

Our Manager: "USERS THE FIRST, CUSTOMER THE PARAMOUNTCY", once the contract is signed, we will fulfill the terms and conditions and strengthen after-sale service and release all the worries from our customers.

Our after-Service: Is your full-service partner of small to large products utilizing up-front engineering support, superior customer services, and state of the art process control techniques. Whole solution from product design, mold design, mold making, rapid prototype, precise injection molding to secondary processing; From idea to product, Hongsen PM is a good answer in China.

Our Mission:

Our mission is to provide the mostservices and products that meet or exceed our customer needs and expectation, in terms of high quality, consistent reliability, on time delivery and reasonable price.

Our Capabilities:

Engineering / Technical, Product Design, Mold Design, Reverse Engineering, Mold Flow Analysis, Project Management.

Mold Build:

Molds up to 1.5 meter and up to 15 tons weight. Hot-runner Capability. Gas-assisted Capability. Double-colored Capability.

Injection Molding:

80 Through 800 Ton Injection Molding Presses. Robotic and Automated Pick and Place. Gas Counter Pressure.

Secondary Operations:

CNC Machining, Oil spraying, Silkscreen printing, Pad printing, Hot stamping, Ultrasonic welding, Bronzing, Solvent Bonding.