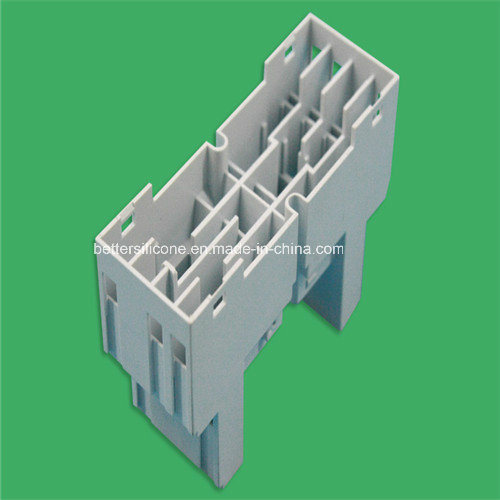

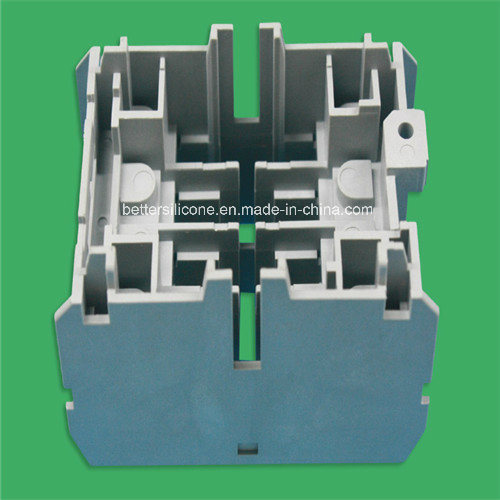

Plastic Protective Relay Switch Part

| Price: |

US $ 1200-1500/Set |

| Trade Terms: |

FOB,CIF |

| Min Order: |

1/Set |

| Pay Type: |

L/C,T/T,Paypal |

Plastic Protective Relay Switch PartBasic InformationService Available:

1. Drawing of Plastic/Rubber/Liquid Silicone Rubber Part in STEP, IGS, DXF, PRT acceptable

2. Mold Tooling Design.

3. Mold Tool Manufacture, Plastic Injection Parts, Liquid Silicone Rubber, Rubber/Silicone Parts, Silicone Promotion Gifts.

4. Liquid Injection Molding, Rubber Molding, LSR Injection Molding.

Equipment:

1. 4 sets CNC Machining Centers

2. 3 sets Wire-Cut EDM

3. 5 sets Die-Sinking EDM

4. 4 sets Grinding/ Drilling Machines;

5. 6 sets Plastic Injection Machinery (60-380 tons)

6. 12 sets Hydraulic rubber machines

7. 1 sets Liquid Silicone Rubber Machinery (Vertical)

| Mould Base | Hasco and Standards |

|

| Mould Steel | LKM | LKM2083 LKM2316A lKM2344 LKM818H LKM838H LKM738H LKM2311 |

| ASSAB(Sweden) | ORVAR8407 IMPAX718S IMPAX718HH PX88 STAVAX S136 STAVAX S136H |

| DAIDO(Japan) | NAK55 NAK80 DC11 DC53 |

| FINKL(America) | P20HH |

| SAARSTAHL(Germany) | GS2344 |

(Germany)

| 1.2344 1.2343 |

| Hot Runner | BUDERS(Germany) | 1.2344 1.2344 |

| Standard Parts | MOULD MASTER,HUSKY, HASCO DME,THERMOPLAY YUDO SYNVENTIVE |

|

| HASCO,DME,MISUMI NEAREST DIN STANDARO LKM |

|

Five production plants:

Five production plants:

1. Mold Tools Making Plants

2. Rubber (Silicone) Plants

3. Plastic Injection Plants

4. Liquid Silicone Rubber Plants (Dust-free)

5. Assembly Plant(Dust-free)

| Prod Model: |

PR-1 |

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Mold Base: |

Lkm |

| Cavity Steel: |

Nak80 |

| Standard Parts: |

Husky |

| Injection Runner: |

Cold |

| Telorance: |

+/-0.03mm |

| Fire: |

Anti |

| Shaping Mode: |

Injection Mould |

| Process Combination Type: |

Single-Process Mode |

| Application: |

Electronic |

| Installation: |

Fixed |

Xiamen Better Silicone Imp/Exp Co., Ltd, as a united corporation, which specialize in producing silicone/rubber/plastic/LSR (liquid silicone rubber) parts and mold tools.

Four Production Plants:

1. Mold-Making Plant;

2. Silicone Rubber Plant;

3. Plastic Injection Plant;

4. LSR Injection Plant.

As a factory managerment cooperation, we focus on improving each factory production efficiency and take full advantage to enjoy customer's demands and meet marketing demand.

Aim to improve make-making technology, company try best to bring in better technologies, talents ect.

Dispensable Fast Reaction: Mold-making, Silicone/rubber/plastic/LSR Plants, experienced technical perons, and managerment system etc.

We have strong team in research field. Any kinds of pattern mould can be developed according to the customer requirement, therefore, many kinds of eco-friendly, high quality silicone products to be showed to the customer. Our silicone raw material brands are Dow Corning, Shin-Etsu, Toshiba, KCC, etc, using these material to provide our customer various of medical and daily commoditties, such as silicone resuscitator parts, silicone kitchen parts, silicone promotion gifts, silicone rubber seal/gasket, silicone auto parts, silicone cell phone parts, silicone shower head, silicone baby goods.

Basing on abound experience, down-to-earth working attitude, innovative spirit and consummative management system, all products can achieved SGS, FDA, ISO9001: 2008 quality managing system certification.

For better quality and service is our motive force source.