Condition New

Type Injection Blow Molding

Style Horizontal

Brand Name zhong chen

Model Number zc-168

Place of Origin Zhejiang, China (Mainland)

Plastic Type Thermoplastic

Automatic Yes

Injection Weight 358 g

Injection Rate 358 g/s

Clamping Force 168T

Opening Stroke 120mm

Power(W) 15kw

Certification ISO9001

After-sales Service Provided Engineers available to service machinery overseas

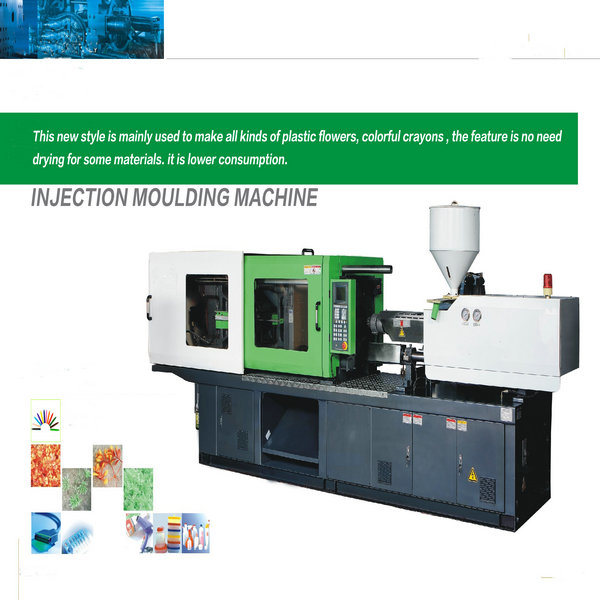

1. This is our new style, we have patent for the technics. For this machine, no need drying material, can put directly to the hopper, no need dehumidity device. No need waiting for the mould. Colors of the products are consistency. No color difference.

2. No need drying cylinder, so can save 72-96degree power, can save lot energy every year

3. Noneed drying and dehumidity cylinder, can save lot production time.

4. For normal machine, need drying material for 3-6 hours before producing, this machine no need this, so can save lot of time and energy. Can save much materials.

Servo power-save injection moulding machine series: There is no extra energy consumption due to output volume changes according to load. In the phase of holding pressure. Servo motor lowers rate and consumes a little of energy. Motor doesn't work and consumes no energy. It can save 20%-80& energy.

Variable displacementt pump injection moulding machine series: High efficient, energy saving and high precise proportional pressure and flow variable displacement pump system makes the hydraulic system output the required power for entire machine operation without high pressure throttle and overflow energy loss. Compared with constant displacement pump, it save power 30% - 60%the motor with same power may fitted with an oil pump of bigger displacement and thus accelerate the machine speed. Besides, the low oil temperature will prolong the service life of sealing elements.

Electronic equipment control:

It is adopted special imported computer of plastic-injection machine& advanced CPU controller, which can raise the operating of control system and warn of excess oil temperature to ensure the working accurancy of machine.

Injection unit:

Double different-pole supporting, double(single)cylinder balance injection screw directly driven by low speed. High torque hydraulic motor and stepless speed got. Screw with optimum design enjoys features of wide application good plasticization and high efficiency. De-compression device to prevent plastic material from dropping.

Clamping unit:

Optimum designed double-toggle five joint clamping mechanism has function such as: Big force enlarge rate, high speed and stable movement, Mechanical and hydraulic and hydraulic eject device with once of multiple eject function

Hydraulic unit:

The unit applies imported advanced hydraulic component, system pressure is controlled through proportional value. In addition, a quick mold clamping device and fast-respond excellent control values are also fitted the unit.

Our company located in zhoushan city, zhejiang province, China. We specialized in making all kinds of screw and barrel for plastics machinery, and diesel generator for marine and civil use, we can also offer photo album.