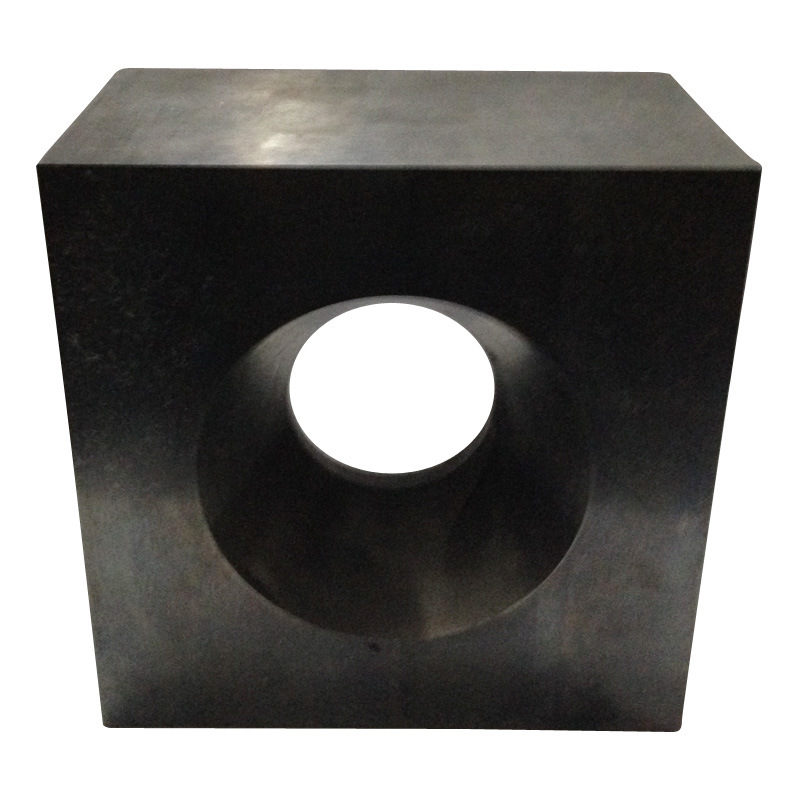

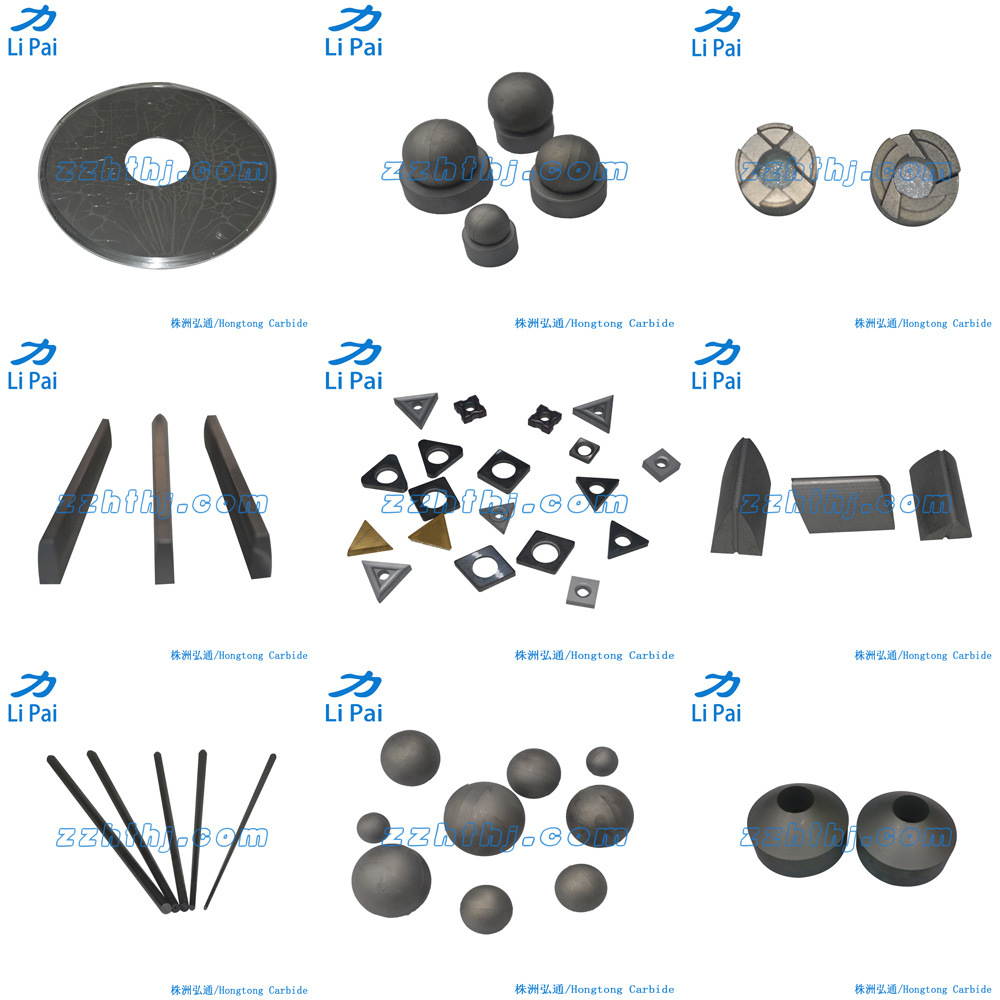

Non-Standard/Customized Tugsten carbide products

Application.

Non-standard/customized tungsten carbide products are usually made from virgin raw material. Using different material grades, like K10 K20 K30 K40 YG6 YG6X YG8 YG10 YG10X YG15 YG20 YG20C YG25 YG25c YN6 YN8 YW1 YW2 YT5 and so on.

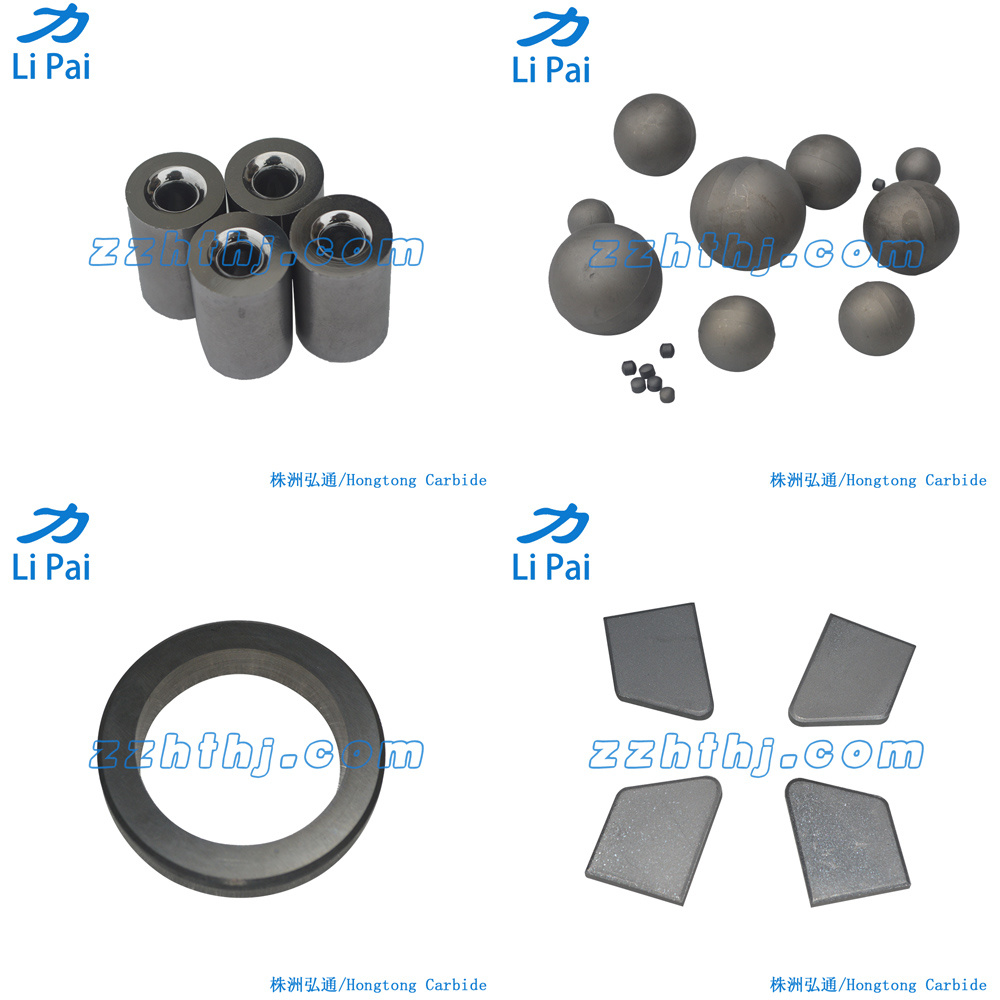

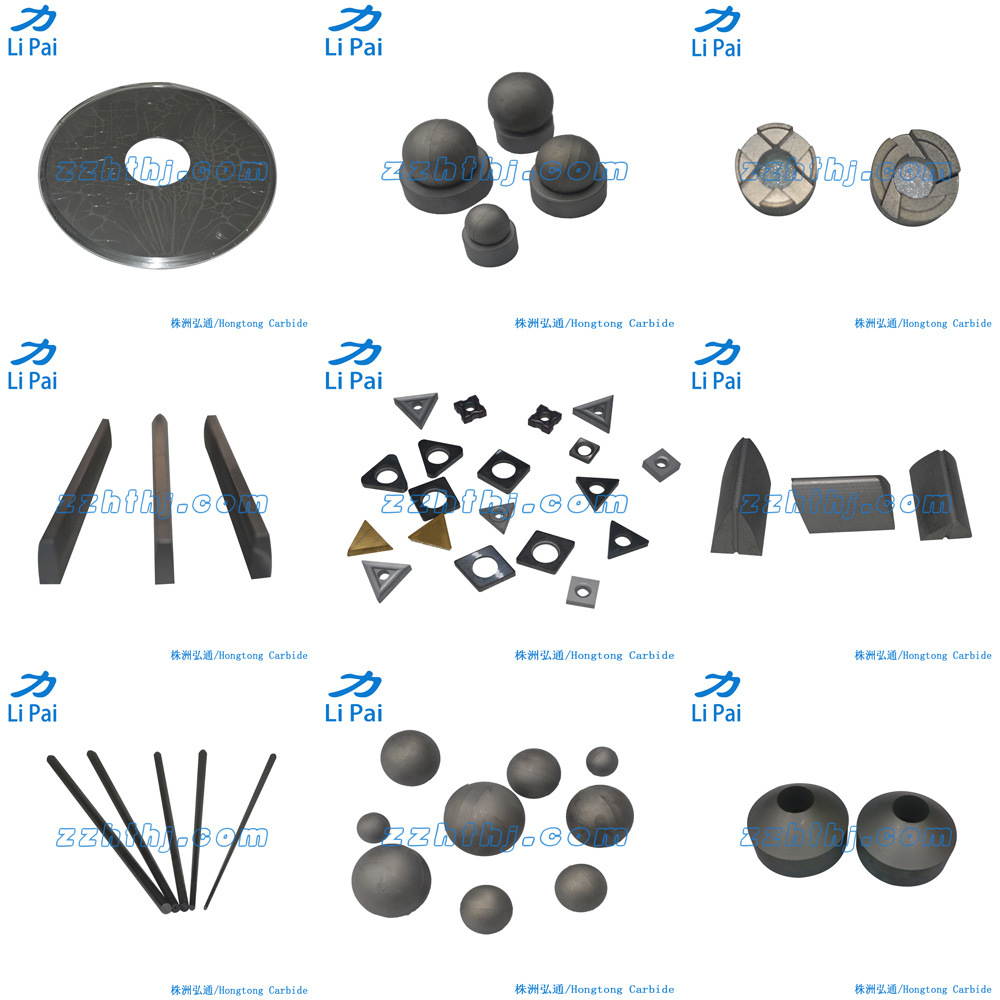

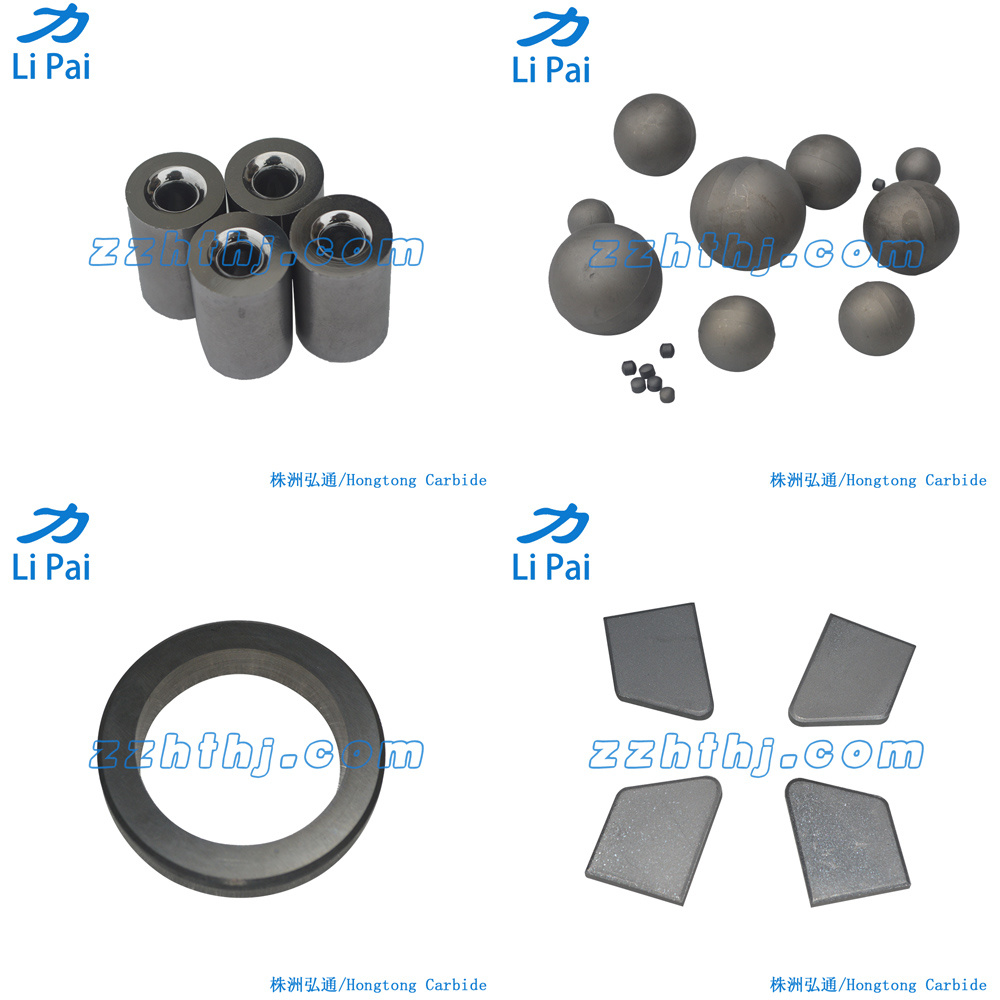

Our products have high hardness,high strenth,high wear resistance and high anti-thermal ability. There're saw tips, gear, special spare parts, non-magnetic parts, special shaped solid carbide products, etc. Above all, it's made from your design and drawing.

No matter how strange your design is, talk to us to see if we could find some way to do it.Properties.

--100% raw material

--HIP sintering

--Superior wear resistance

--High hardness and mechanical strength

--Good corrosion resistance

--High precision for tolerance

--Quality Control System and strict inspection.

--Feedback within 24 hours

--Flexibility of payment term

--Fast delivery

--Exellent after-sale service

Grades recommend.

| Grade/ Properties / Application |

|

| Grade | Equal to ISO Category Number | Performance | Performance&application recommended |

| Density | Bend Strength | Hardness |

| G/Cm 3 | N/mm 2 | HRA |

| YG3 | K01 | 14.9-15.3 | ≥1180 | ≥90.5 | Sand-blasting nozzles qualified for fine turning and half-fine turning when cast iron, non-ferrous metal, alloys as well as non-alloy materials cutting consecutively. Can make wire drawing of steel and non-ferrous metal. Also qualified for sand-blasting n |

| YG3X | K01 | 15.1-15.4 | ≥1300 | ≥91.5 |

| YK05 |

| 14.95 | 2500 | 90.5 | Mostly used as the buttons of small and bits medium sized percussion |

| YG8C |

| 14.8 | 2400 | 88.5 | and as the inserts of rotary prospecting bits to cut soft and |

| medium hard formations. |

| YG6 |

| 14.95 | 1900 | 90.5 | For coring crowns,electric coal drill bits, coal cutting picks,oil |

| cone bits and scraping knife bits,used in coal geological prospecting, |

| mining and oil well boring. |

| YG6X | K10 | 14.8-15.1 | ≥1560 | ≥91.0 | Qualified for machining of chilled cast iron, alloy cast iron, refractory steel and alloy steel. Also Qualified for the machining of common cast iron. |

| YG6A | K10 | 14.7-15.1 | ≥1580 | ≥91.0 |

| YG6 | K20 | 14.7-15.1 | ≥1670 | ≥89.5 | Qualified for finish machining and semi-finish machining for the cast iron, non-ferrous metal, alloy and unalloyed materials. Also qualified for wire drawing for the steel and non-ferrous metal, electric drill for geology use and steel drill etc. |

| YG8 | K30 | 14.6-14.9 | ≥1840 | ≥89 | Qualified for rough machining of cast iron, non-ferrous metal, nonmetal materials, drawing of steel, non-ferrous metal and pipes, various drills for geology use, tools for machine manufacture and wearing parts. |

| YG10X |

| 14.5 | 2400 | 91.5 | Fine grain alloy, good wear resistance,Used for processing hard |

| wood, veneer board,PCB,PVC and metals. |

| YG11 |

| 14.4 | 2600 | 88.5 | Forming or stamping dies for metal powders and nonmental powders. |

| YG11C | K40 | 14.4 | 2700 | 86.5 | Largely for the inserts and buttons of percussion bits and tricone bits to cut medium |

| hard, hard and very hard formations. |

| YG15 | K40 | 14 | 2800 | 87.5 | For fabricating drawing dies of steel tubesand rods under high |

| compressibility ratio;punching,stamping,forging tools under large stress. |

| YG15C |

| 14 | 3000 | 85.5 | For oil cone dril bits, for medium soft and medium-hard rocks. |

| YG16C |

| 13.9 | 2900 | 85.5 | Impact resistance, hot&forging dies etc. |

| YGH40 |

| 13.5-13.9 | ≥2450 | ≥83.0 | Mainly for making hot dies. |

| YG20 |

| 13.5 | 3200 | 85.5 | For fabricating of stamping dies for watch parts, spring plates of musical |

| instruments, battery jars,small sized steel balls,screws,screw caps. |

| YG18C |

| 13.7 | 3100 | 84.5 | Impact resistance forging dies,hot-press forging dies and rollers. |

| YG20C |

| 13.5 | 3300 | 83.5 | Dies for wear resistant or impact resistant application. |

| YG22C |

| 13.3 | 3500 | 83 | Nut forming dies and high impact resistance forging dies. |

| YG25C |

| 13.1 | 3600 | 82.5 | Stainless bolt header dies and rollers. |

| YT15 | P10 | 11.1-11.6 | ≥1180 | ≥91.0 | Qualified for rough machining, semi-finish machining and finish machining during consecutive machining of carbon steel and alloy steel. |

| YT14 | P20 | 11.2-11.8 | ≥1270 | ≥90.5 | Qualified for rough machining for rough face of carbon steel and alloy steel, half process during discontinuity cutting. |

| YT5 | P30 | 12.5-13.2 | ≥1430 | ≥89.5 | Qualified for rough machining for rough face of carbon steel and alloy steel and discontinuity cutting. |

Company info.Zhuzhou Hongtong, a professional Chinese manufacturer of tungsten carbide products. Located in city of Zhuzhou, the base of chinese tungsten carbide technology.We supply tungsten carbide ball/seat, seal ring,plate,strip,nozzle,rod,brazed tips,mining tips,inserts,disc cutter,wire drawing die,cold heading die,and so on.

Company info.Zhuzhou Hongtong, a professional Chinese manufacturer of tungsten carbide products. Located in city of Zhuzhou, the base of chinese tungsten carbide technology.We supply tungsten carbide ball/seat, seal ring,plate,strip,nozzle,rod,brazed tips,mining tips,inserts,disc cutter,wire drawing die,cold heading die,and so on.

Our senior engineers are engaged in carbide industry for decades, and full of experience. We have strict quality control system and our laboratory includes all kinds of testing instrument. We can analyse every aspect of carbide products, such as Metallurgy property,hardness, bending strength, grain size, etc.

With more than 10 years experience, we can do more than you can image.Contact.Arris Zhang

Oversea sales manager

Mobil: 86 13974173665

Web: www.zzhthj.com

Add: No.86, Mingri Rd, Tianyuan Dist,Zhuzhou,Hunan,China.

Postal:412007

Our company is a professional tungsten carbide manufacturer in Zhuzhou City, which is the world-renowned research and production base of tungsten carbide products. Our company has more than 10 years' Rich experience in this field.

We always expect long-term relationships with customers. You can find the best prices, quality and services here and it will be simple and easy for you to do business with us.

Strict quality control system ensures that our products can satisfy or exceed your requests and we guarantee full payment will be returned if there is any quality problem.

Zhuzhou Hongtong Tungsten Carbide Co., Ltd., located at Liyu Industrial Park, Zhuzhou National High-tech Development Zone, is a high-tech joint-equity enterprise integrating R&D, production and marketing of cemented carbide series products.

The company sets up an independent production and R&D base, covering a total area of 7, 000m2 and a plant area of 4, 000m2. There is a group of experienced technical personnel and a staff of 80 people including 5 engineers, 8 assistant engineers, and 29 people having college degree or above. The company mainly produces cemented carbide drawing dies, cold heading dies, mining tools, sealing rings, and other nonstandard products, wherein the cemented carbide drawing dies and cold heading dies take a leading position in the industry, and the bore of wire-drawing die can be minimized to 0.1mm, deeply popular with customers.

The company adheres to the quality policy of "Technological Innovation, Stringent Process Control, Pursuit of Quality, Customer First", and highly stresses internal management and product quality control. Through many years of development, its management level and product quality reach a higher level, winning a good reputation in the industry.

The company sincerely thanks new and old customers for their trust and support over these years, and seriously promises to provide better products and service.

It will be a satisfactory cooperation.