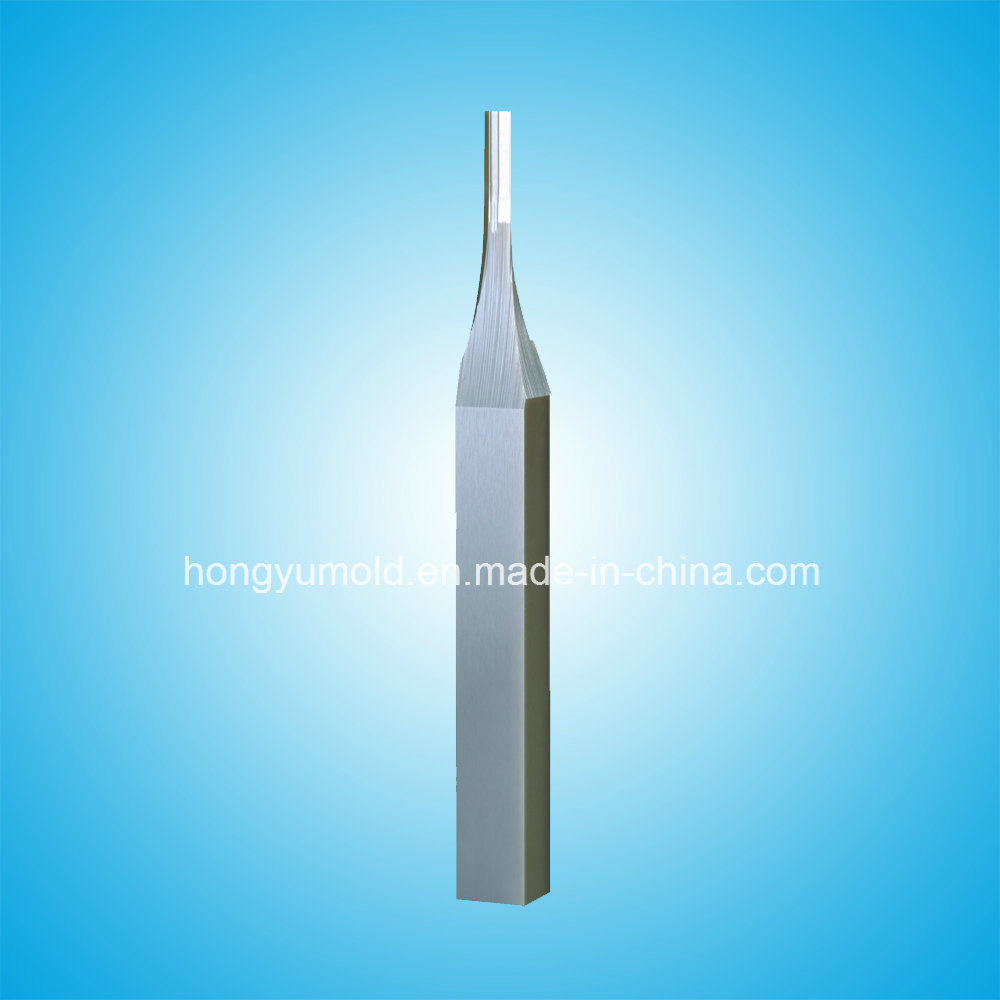

Precision Ceramic Parts for Stamping Mould (Proile grinding punch)

| Price: |

US $ 35/Piece |

| Trade Terms: |

FOB,CIF |

| Min Order: |

1/Piece |

| Pay Type: |

T/T |

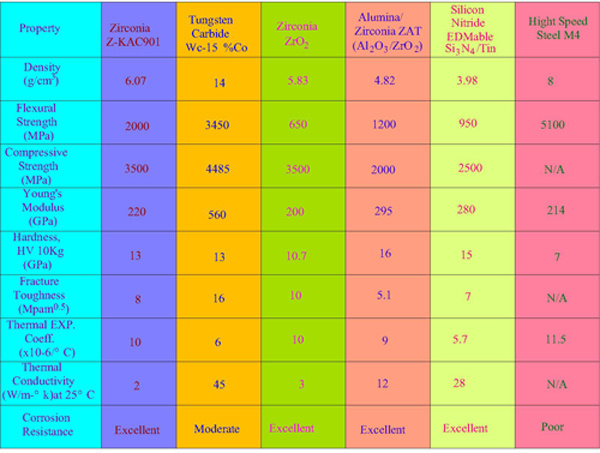

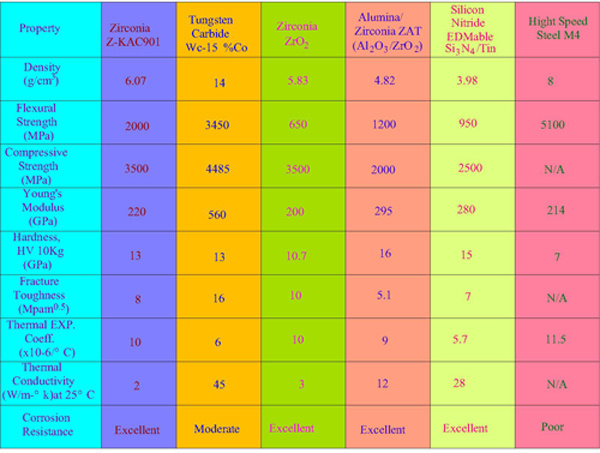

Special Introductions:1. MaterialProperty:Code: Z-KAC901, American ceramics with brown color, hardness is HRA90.0. Compared with tungsten carbide, please refer to the below table: Features: Excellent corrosion resistance, not easy to be eroded and decomposed. Can avoid sticking and scraping material problem. Light weight, density less than half of tungsten carbide. Single crystal phase homogeneous fine organizational structure. Full compact nonporous material Having very low friction coefficient. Suitable for precision metal mould, bending moulds, stamping mould and parts with high wear resistance. 2. ProcessingNow we can only do grinding for ceramics. Due to the non-conducting feature, we can not do wire cutting and EDM for ceramics parts. This part processed with surface grinding and profile grinding.

Features: Excellent corrosion resistance, not easy to be eroded and decomposed. Can avoid sticking and scraping material problem. Light weight, density less than half of tungsten carbide. Single crystal phase homogeneous fine organizational structure. Full compact nonporous material Having very low friction coefficient. Suitable for precision metal mould, bending moulds, stamping mould and parts with high wear resistance. 2. ProcessingNow we can only do grinding for ceramics. Due to the non-conducting feature, we can not do wire cutting and EDM for ceramics parts. This part processed with surface grinding and profile grinding. 3. Quality CheckWe have well-equipped QC department, and we do full QC for every part.

3. Quality CheckWe have well-equipped QC department, and we do full QC for every part.  If you want to know more, please contact us!

If you want to know more, please contact us!

| Markets: |

North America,South America,Eastern Europe,Southeast Asia,Africa,Oceania,Mid East,Eastern Asia,Western Europe |

| Name: |

Ceramics Punch |

| Processing Way: |

Pg(Profile Grinding) |

| Size: |

5mm*4mm*50mm |

| Tolerance: |

0.002mm |

| Cutting Length: |

8mm |

| Application: |

Stamping Mould |

| Processing Method: |

Punching and Shearing Mould |

| Technics: |

Cutting Die |

| Process Combination: |

Progressive Die |

| Manufacturing Technology: |

Automation Technology |

| Driving Motor Type: |

Permanent Magnet |

| Milling Speed: |

High Speed |

| Parts Detection Method: |

Geometric Detection |

| Material: |

Ceramics |

| Mold Cavity Technology: |

Pg |

HONGYU Mould Co., Ltd specializes in high precision parts for press molding/ Punching molding/ tungsten carbide molding component/metal tools/ Motor core dies/ SMD mould/ Connector molding parts/ tungsten, steel mold grinding/CNC optical profile grinding/ CNC wire cutting

Manufacturing/precision elec. Discharge

Machining/processing plastic molding component/mirror surface processing/electric pieces of wire cutting machines. Last year we have developed good CNC grinding surface S0.2 (Ra0.04um) with high accuracy quality.

In possession of well known imported equipment including Swiss CNC wire cutting machines/ Sodick wire cutting machine/ Japanese CNC profile grinding machines/Taiwanese elec. Discharge machines/ Taiwanese surface grinding machines and other machines, we can provide high quality, reasonable price products and best service in time.

Our company persists in the principle of "customers as the center, quality as the basement of company's development and service". For finished products, we set up necessary professional testing and measuring equipment including NIKON-V1213 projector, Accretech Contourecord 1600G, Nikon Dig micro altimeter MS-11C, Mitutoyo dig micrometer caliper IP65 and Toolmaker Microscope CURO VM-GI.

We are one of most professional team with over 40 technical employees. We are not very big but we are very proud of our product quality and we do believe that we can provide the best service. We will continue to satisfy all overseas customers and local friends by high quality products, reasonable prices and the best services.

Address: 126 Xinma Road, xinmalian village, Dalang town, Dongguan City,

Guangdong province, China.

Postal code: 523785

Tel: +86 769 83203300 83011518 83011519

Fax: +86 769 83202200