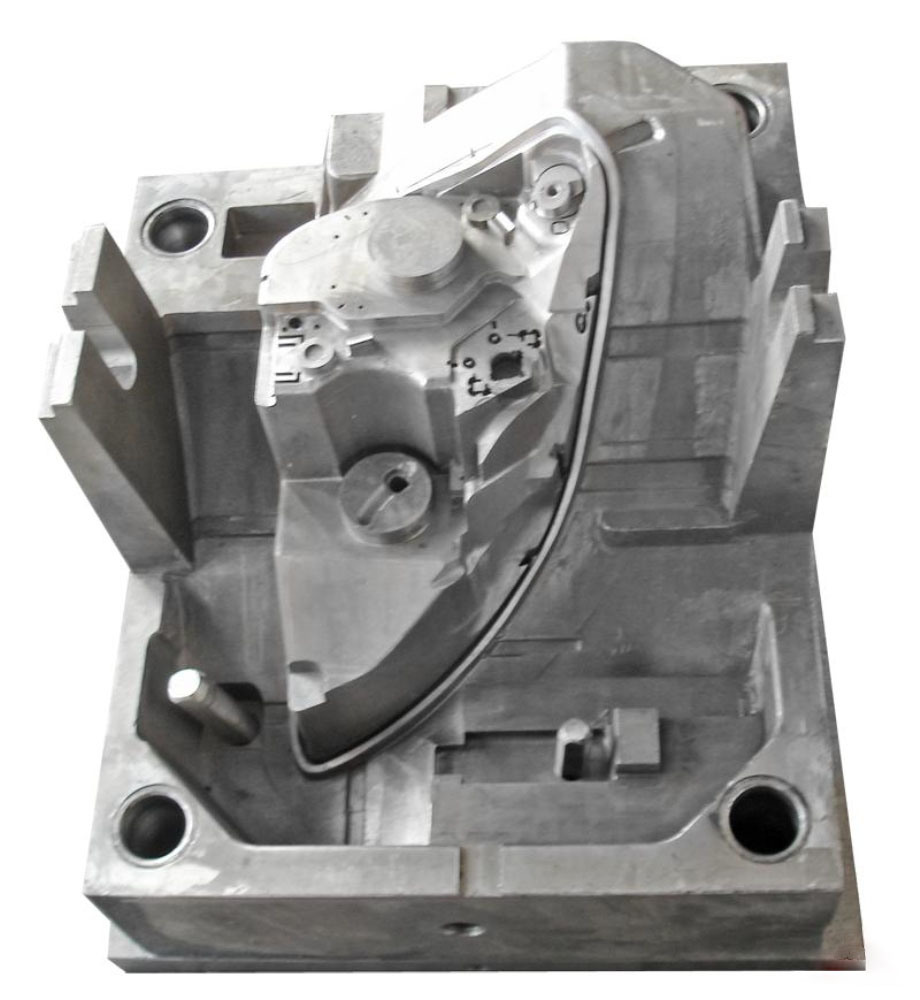

Plastic Injection Mold for Auto Parts Mould

Plastic injection molding, China Plastic Injection Mold Manufacturer

1. Negotiations: Provide timely and accurate quotation in 24 hours.

2. R&D: We can offer Parts' concept design, Moldflow analysis and Full 3D mold design. Have rich experience on export molds

3. Design confirmation: Professional project engineer will communicate with customer directly, solving technical problem and feedback the project processing.

4. Mould processing: QC engineer will control each of processing carefully. Meanwhile we operate 2 shifts work system to win the time for customers

5. Sample confirm: Each of samples will be checked before shipping. Using the fastest express company, Such as, DHL, UPS, FedEx.

6. Delivery: Trade term can be EXW, FOB, CIF, DDU, DDP by sea or air freight based on customer's request. Booked in advance.

Images:

Features:

1) We can provide plastic moulds for various parts according to your requirements

2) We own CNC processing centers, CNC spark working machinery and various advanced mold tooling equipment. We also have established a CAD / CAM / CAE mold design and development center

3) Our quality, price, after sale services are really competitive

4) Our range covers from eletrical accessory, auto parts, household appliance, computer accessory, medical appliance, car accessory, digital&security parts ect.

About Us

Shenzhen Good Vision Technology Co., LTD is a interprise which focus on a series of process including desiging, developing, producting, packaging, marketing and have passed the ISO9001: 2008 Quality System Certification in 2007.

At present, the factory building is about 10000 meters and supporting 10000 level clean production workshop, have built a international Modernization manufacturing production chain and brought together a group of efficient service team with experienced and skillful, they are able to design and manufacture high-quality products by using a variety of advanced software skillfully.

The Mikron high speed CNC machine guarantee precision and high quality mold manufacturing; The precision EDM machine from charmilles enhances the performance of the EDM precess by improvint the machining conditions. The advanced Projector and CMM Measurement Equipment to assurance the product's quality and enhance the stability.

The plant fully carries out 7s work, gradually improves ISO quality control system, as the excellent sound management mechanism; We already be a high quality partners with a number of well-known brands enterprises from domestic and foreign.

|

Material of Core & Cavity |

Cav. |

Mould Base |

Mould life(shots) |

Surface/Texture |

|

P20 718H NAK80 2316 SAARSRAHL AG 1.2311 |

1*1 |

LKM LKM (HASCO 50#) DME |

300000 500, 000 1000, 1000 |

EDM MOLDTECH High Polish |

|

|

|

|

|

|

|

Machine |

Lead Time |

Special |

Advantage |

|

|

Advance CNC, EDM, W-cut |

30 Days |

Glossy Surface |

High Polish |

|

|

|

|

|

|

|

|

Products Details: |

|

|

|

|

|

Dimension (mm) |

Material |

Dimension control |

Tolerance |

|

|

|

|

2D/3D Device |

0.02mm |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Shenzhen Good-Vision Technology Co, Ltd is the leading plastic moulds manufacturer in China, Based on the precision tooling, high technology and top mentality mould design. Jsl mould has established the main market in Spain, Brazil, Sweden, Australia, Ireland, U. S. A and etc.

Our products covers Plastic injection molding, Plastic blow molding, BMC/SMC/DMC/GMT glass fiber mold, Plastic injection molded products and Metallic punch products.

We use PRO-E, Solidworks, U. G., and Auto-CAD for moulds and products design, with very strong mould design and drawing reading ability. This ensures the good technical communications with clients, which can avoid any mistake occur.

We have utilized modern equipment such as CNC machining center, EDM machine and EDM wire cutting machine. Modern CAD/CAM/CAE systems, such as those using UG, ProE, Solidworks and Cimatron, are also in place to assure the quality of our molds and molded products.

There are more than 3000 square meters Anti-dust work shop in our factory, we do OEM and ODM IML, IMD products such like IML panel, IMD cover, we are strictly for contro quality, our management team are run in ISO9001-2008 system.

Our mission is to provide our customers high quality products and services. We aim to exceed our customers' expectations in terms of pricing, quality and on-time delivery.

Currently we are making IML and IMD products it like mobiphone housing, Switch pannel, Remote-Control, Touch pannel for home electronic products. And some specially technical like Thin wall injection, double injection and so on.

We are Located in: ShanKeng Industrial Park, No. 100 Keyuan West Road, Shanxia Village, Pinghu Street, Longgang District, Shenzhen, just 1 hour bus ride from Shenzhen International Airport and 2 hours from Hongkong International Airport.

The company owns modern standard Mold workshop and 100K-class Clean injection Room with an area of 10, 000 square meters. It has set up precision mold division, ordinary injection molding division, IML/IMD injection molding division, and silk screen division. By virtue of standard production and management mode, as well as precise mould processing equipment and advanced injection molding equipment, it provides customers of high quality consumer electronic plastic products by OEM and ODM. The company is committed to providing iPhone4 peripheral accessories and Ideal products for the iPhone4 users.

"High Quality, Good Faith, Sincere Service, Customer Supremacy" is the company's business philosophy. "Quality, Efficiency, Innovation" is its professional spirit. The company advocates the humanism of "Respect, Understanding, Encouragement, Progress, Innovation". It wishes to make Business cooperation with friends from all over the world.

Welcome to visit our factory, we are glad to meet you in China.