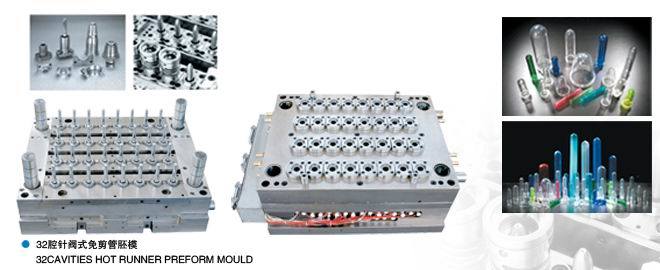

Usually, Multi-cavity pet preform mould does use the hot runner system rather than cold runner system, so the design of hot runner system plays an important role in mould quality guarantee. Based on foreign advanced techniques and combined with domestic clients demand, we adopt the valve gated design, in which each cavity has its own heating zone and temperature is measured by independent thermocouple. (advantages: Easily avoid some problems such as white or drawbench on bottom). Here, Mould is produced automatically to reduce labor force.

Main mould components (die core, die cavity, screw neck) are made by injection process, and the material of which originates from Sweden high-quality mould steel (HRC 45). In this way, it is no doubt that the mould can be used for 2 million shots without any maintenance, meanwhile, the wall thickness between max. Part and min. Part is not more than 0.05mm; Turning center processes make sure that every parts can match well; Proper distribution of cooling water way improve productivity effect and molding cycle only takes 15 seconds( need proper water chiller, bottle design and injection machine)

Our mould, designed and developed by our engineers, is of high precision and long life span without traditional problems. In a word, Preform wall thickness is on error of 0.05mm; Weight difference is less than 0.3g; 2-5 moulds per minute; 2 million guarantee; Utmost 144 cavities in one mould.

Main feature:

1. Mold cavity from 1 up to 144.

2. Electric control system with simulating stretch testing improve yield rate.

3. Adopt world advanced dipole taper localization technique, each cavity self-clamp independently, ensure mould concentricity.

4. The material of mould die core and die cavity are made of Sweden special mould steel.

5. International standard screw neck, imported nitrided steel with high hardness is of long usage.

6. Advanced hot runner design and even heating temperature make sure the high quality of plastic products.

7. Valve gated type without tail reduces labor force.

8. At least 2 million guarantee.

Zhejiang Demark Machinery Co., Ltd., a modern enterprise, professionally designs and manufactures a series of high speed rotary pet stretch blow molding machines and pet preform mould. Up to now, we have developed many different types of blow moulding machines to meet customers' need, which support plastic containers from 100ml to 2l. Located in huangyan--"blow molding machine town" in China, our company covers 50 thousand square meters with total investment of USD 10 million. We are devoting ourselves to technical research in order to build up a good reputation & famous brand.

We have already established business relations with more than 50 countries in Asian, Middle East, Europe, Africa, America, Australia.

There are departments special for machinery development and pet preform mould development. By foreign advanced technology and management system, under advantage of our solid technical power (professional engineers, large-scaled workshops, good design techniques), we are capable of having been developing different kinds of plastic forming process and machinery to supply the best quality products and service to the customers. High quality but reasonable price has been widely approved by our customers both in home and abroad.

Focused on customers, cored on quality, the corporation and customers are viewed as a united whole. Customers' requirements are all we should do.