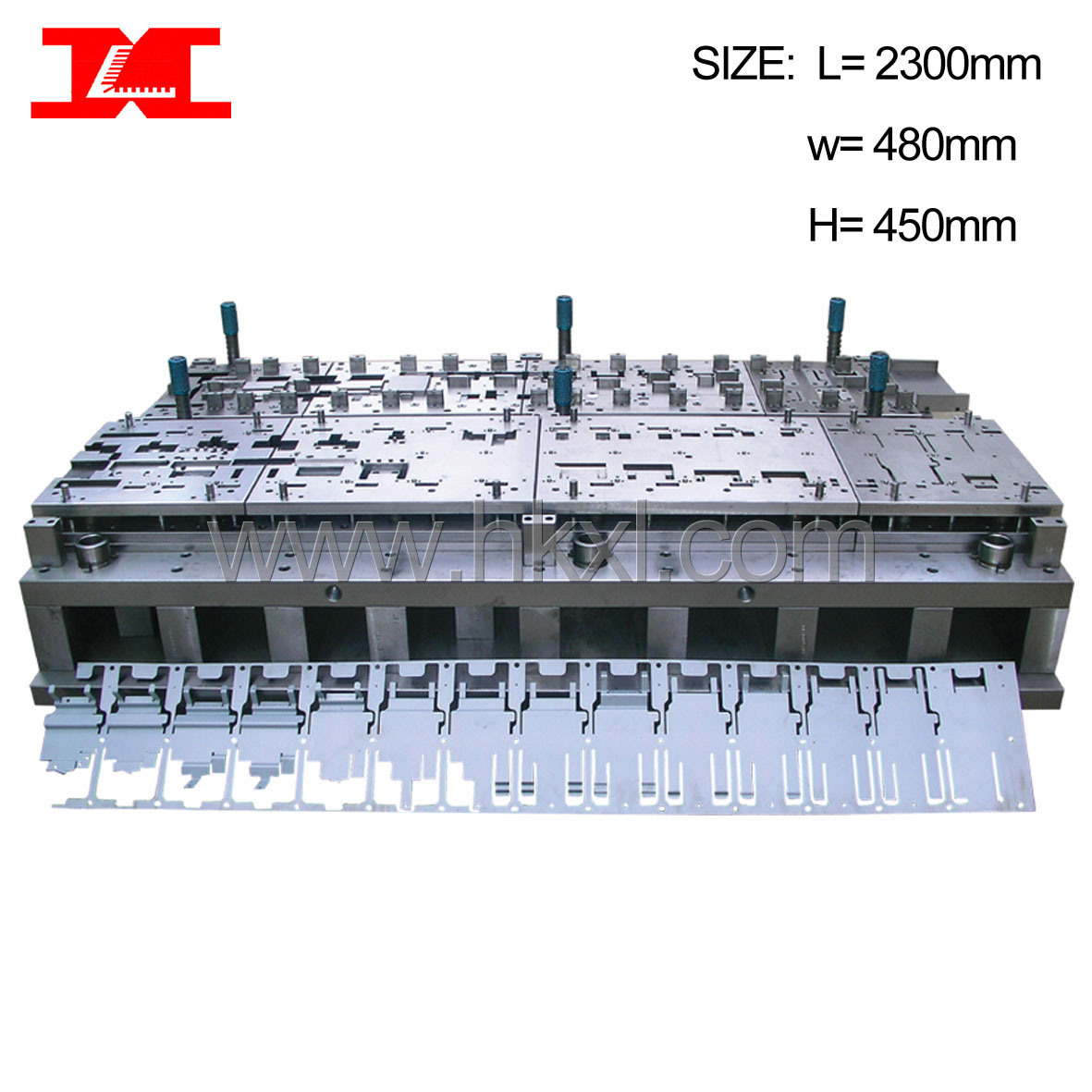

16 years experience in design and making precision metal stamping die/mould and stamping parts. All processes are finished in house. Progressive die, Compound die or Stage die are up to customer, with DANLY, KALLER, FIBRO, MISUMI standard, ISO9001: 2008.

|

TITLE |

Precision progressive die, compound die, stage die, stamping die, stamping mould, stamping tooling, stamping mold; |

|

STANDARD |

DANLY, KALLER, FIBRO, MISUMI, etc… |

|

MATERIAL |

Base steel: 45# Steel or according to customer' s requirements |

|

Cutting & Forming steel: SKD11/DC53/A2 or according to customer' s requirements |

|

PROCESS |

Purcahse order→ Engineering appraise and Request for change→ Layout design→ New product meeting→ Die design and Material plan→ Incoming material check→ Die processing→ Die Assembly→ Die trial→ Sample check→ Sample Hung Lee internal approval→ Sample submission→ Die Buyoff |

|

FINISH |

Hard chrome/Nitrogen/TD treatment etc... |

|

The type of surface treatment depends on the volume or according to customer' s requirement |

|

INSPECTION |

Layout will send to customer for approval before die making. |

|

5~10 Samples with full dimension report send to customer for approval before delivery. |

|

CD record with construction/part drawing will be delivered with the dies. |

|

PACKAGING |

Wooden case, fumigation treatment. |

|

LEADTIME |

20 to 30 days |

|

TRADE TERMS |

FOB, CIF |

|

OTHERS |

RoHS compliant; ISO9001: 2008 |

Hung Lee Enterprise Co., Ltd was established in Hong Kong, with ISO 9001 certified factory Hung Kam Metal&Plastic Manufacturing Factory since 1995 in China mainland. We are a professional manufacturer of metal and plastic products, stamping die and injection mold. Our metal OEM ability ranges from computer enclosure, typewriter and printer components, auto parts, TV covers to cooling machine parts and all kinds of metal boxes. Our plastic manufacturing ability ranges from pharmaceutical plastic parts to automotive plastic parts. The tooling covers single dies (stage dies), large & medium size progressive dies, transfer dies, injection moulds and so on. All the tooling and products are made in house, with RoHS compliance.

With an area of 10, 000 square meters, experienced mould makers, quality engineers and technicians, Hung Lee adopts general 2D/3D software in die designing. The international standard parts used in moulding are Danly, Kaller, Fibro, Misumi, etc. The tooling machining facilities are precisely computerized numerical controlled. We have 3 sets of large CNC Machines, 4 sets of precise slow-speed wire-cutting machines, over 70 pressing machines with the pressing capability ranges from 25 tons to 500 tons. "Better mould, Better products. " We strongly hold that quality, prompt delivery and good after-sale service is the lifeline of a company.

Our customers come from all over the world, such as Bosch, Sony, Canon, IBM, Siemens, Lenovo, HP, FUJI Xerox and so on.

We sincerely welcome every customers to our company. Thank you!