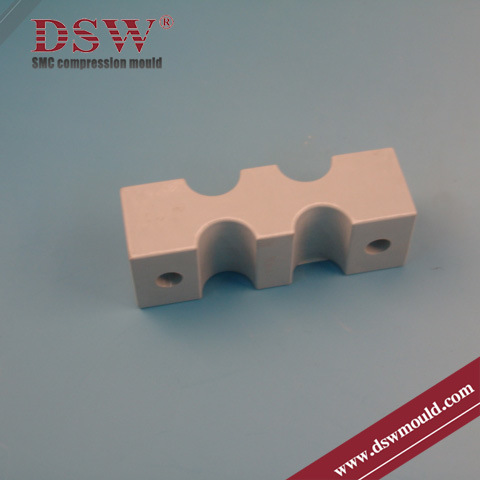

Compression Mould

1. SMC Compression Mould

2. BMC Compression Mould

3. Compression Mould with high quality

4. Compression Mould design

5. Sample time: 20~ 30days.

More feature and specifications:

(1)Quality assurance: ISO 9000.

(2)Material: ABS, PP, PC, PBT, PVC, PA6, PA66, TPEE, PC+ABS, etc.

Business Scope:

1. Plastic Mold designing.

2. Mould and parts making

3. Parts machining

4. Injection molding

5. CNC prototype manufacturing

(6)Injection parts' surface treatment: Color painting, Texture, Silk-printing, Anodize etc.

(7)ODM&OEM service

(8)CAD Software: Pro/engineer, Solidworks, UG, Auto cad.

(9)Mold Making Time: 15-35 days

(10)Mold Lift Time: 100000-500000pieces, depend on customer requirement

(11)Mould Base: LKM, FUTA, HASCO, DME, etc. Or as per customer' s requirement.

Cavity:

Single cavity, Multi Cavity, based on customer' s requirement.

Mould Life: 100, 000 to 1, 000, 000 shots

Service: Mould making, parts make, parts design, parts assemble...Etc

Equipments: CNC, EDM, ArgieCharmilles, Milling Machine, 3D CMM, Projector, HG, Injection Machines

Mold building lead time 2-8 weeks ( normal, within 4 weeks)

Plastic part scope plastic spare parts for automobiles, motorcycles, household appliances, And other industrial OEM projects

Surface finish and color according to customers' needs

Packaging Inner packing--Polythene bags, outer packing--Paper cases suitable for transportation by air or sea.

Established in 1998, DSW Industry Co., Ltd has specilized in making plastic injection, plastic injection mold, aluminum die casting, progressive dies for LED industry, heatsink, valve part, fitting, impellers, hardware tool, machinery part, auto part, pneumatic, medical, petrochemical, marineaccessories in all of world, mainly service for oversea customers.

DSW diecasting occupies an area of 3000 square meters, having around 80 employees, with USD 4 million export annually.

DSW plastic injection & mold occupies an area of 1500 square meters, having around 36 employees, with USD 3million export annually.

DSW stamping occupies an area of 800 square meters, having around 25 employees, with USD 3million export annually.

At DSW enterprise., we are extremely proud of the hard work we've put into becoming and maintaining our ISO 9001 certification. We are confident that you will appreciate when deadlines are met and products are manufactured to specification. Satisfied the customers with our excellent quality of product, reasonable price, perfect service after sale.