UNGAR CO., LTD. is an Austrian company in Shanghai China specializes in:

-aluminium foil container machine

-aluminium foil container mould

-aluminium foil rewinding machine

Welcome old and new customer visit our booth at 2N 2D18 during ALUMINUM CHINA 2015 show which will beheld from 8th. to 10th. July 2015 in SHANGHAI NEW INTERNATIONAL EXHIBITION CENTER.

Product Description

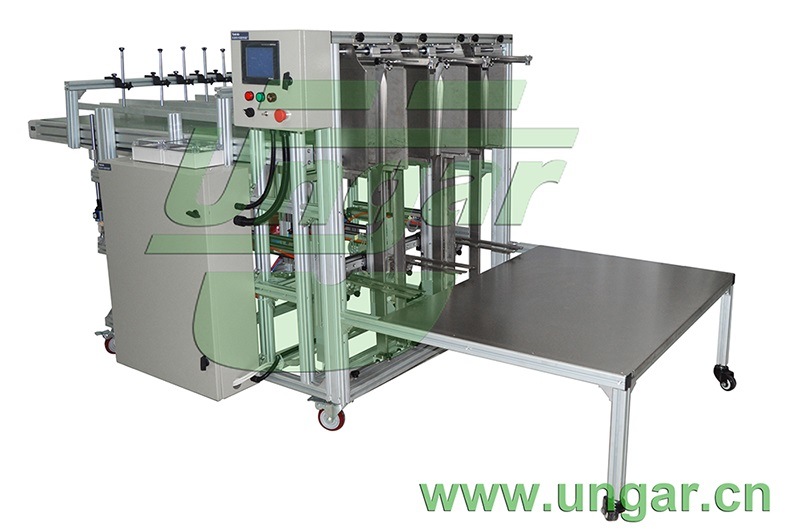

Automatic stacker is a working unit used on "aluminium foil container machine

Specifications:

Auto container stacker

Model:UNST-6010(The UNST-6010 is for 55Ton/63Ton/80Ton/110Ton,with 1 to 4 lanes) |

| Collector belt width | 600mm/800mm |

| Collector belt heihgt | 1100 ±100mm (According press machine's size, we will adjustable height system on requested) |

| Min. container dimensions | 100x 100mm(Smaller on request) |

| Container dimensions | 450 x 340mm(1 lane) 230 x 340mm(2 Lines)

The lanes could be less or more on your condition, also depend on container shape. |

| Max. height of container stack | 420mm(Depend on the container shape and size) |

| Lifting system | By step motor and linear guide |

| Photocell electronic counting device | Container counter automatically stops press at top of stroke in emergency situations. |

| Control panel | Automatic Touch screen panel |

| Stacking system | Photo electric sensor controls the height of the stack with electric brake system. |

| Installed Power | 1Kw |

| Air consumption(2lanes) | 0.1m3/Min |

| Net.weight | 300kg |

| Stacker dimensions(L*W*H) | 55ton:3200x1050x1400(+-100mm)mm; 63ton:3200x1300x1400mm; 80ton:3200x1530x1400mm; 110ton:3200x1790x1400mm |

| Notice:The Stackers specifications depend on container size and shape and the mould cavities. |

Advantage:

1. Designing for labor saving and production efficiency.

2. Stack trays and containers of different dimensions.

3. Easy to operate and adjust based on customize requirements.

UNGAR (Shanghai) Co., Ltd is an Austrian enterprise established in 2009 supplying high productive multi-cavity mould and machinery which includes press, stacker, package, re-winder, paper lid cutting, decoiler, scrap aspirator and additional equipments. UNGAR complete integrated production line has been specially designed and developed for the production of aluminum food container and trays.

UNGAR (Shanghai) Co., Ltd as a technology leader focusing on researching and developing new products with a professional design team, technical department and sales group. In this way, the design team with its headquarter in Austria, manufacturing factory located in Shanghai, professional engineers service and global sales linking by Europe, America, Middle East Gul-food area and most of Asian countries.

UNGAR (Shanghai) Co., Ltd also offer customized service for technical optimization, mould prove, machine installation, material test, training course, telephone assistance and so on. UNGAR more than just a manufacturer...

UNGAR success can be attributed to the cohesive team environment, both at a state and international level; By drawing from each states market experience, group buying capabilities and deep knowledge pool, UNGAR dynamic team has cemented their company's position as market leader.

Management Team

UNGAR team of long standing managers provide guidance and direction, drawing from their solid experience and industry knowledge, ensure the company's strategic direction leads to a successful future.

Marketing Team

The team's key responsibility is to ensure that UNGAR broad range of and product ranges are communicated effectively both internally and externally; With a thorough understanding of product development, promotion, release strategies, training, and evaluation we ensure our products are designed to meet your needs.

Procurement

The procurement team brings a wealth of experience to an extremely important role, with the coordinate efforts the procurement team ensures UNGAR products are in-stock when you need it.

Accounts

The accounts teams are responsible for the day-to-day balances and checks of all financial transactions, giving stakeholder's confidence in their long term business relationships with UNGAR.

UNGAR's professional design team with 5 experienced designers in mechanical, pneumatical, and electrical field with more than 10years designing experiance. Headquater localed in Viena Austria.

Our Advantage and Service

Welded body with steel plate and high intensity.

Main motor is made by Siemens.

Adopts combined pneumatic friction clutch and brake.

Cluster gear adopts the flooding oil lubrication.

Six-face rectangle lengthen guide;

Equipped with hydraulic overload protecting device.

Electric shut height adjustment with digital display.

Equipped with lifting balance cylinder.

Welded body with steel plate and high intensity.