steel moulds for precast concrete

1. Basic Information

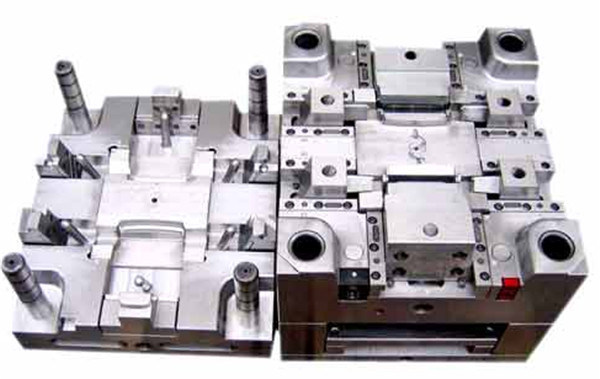

Mold type: all tyes of produts plastic mould

Mould base material: #45.LKM, LYM standard etc

Mould spare parts material: Jinghong, HASCO, DME etc

Hardness of steel: 28-50HRC

Mould design: 3D/2D drawings

Runner: cold runner

Design days: 1-3days

Mould life: 500,000-3,000,000 shots

Plastic material: PE, PC, PS, PP, PA, ABS, etc

Injection system : pin point gate

2. Quality Reference

Level A: 1,000,000 shots — high

Level B: 800,000 shots — middle

Level C: 500,000 shots — normal

3. Application

Communication/Electronic/Auto parts/Surveillance products/Medical device/equipment and so on .

4. Customers assistance for initial detailed quotation on plastic injection molding

1) 2D/3D Design drawings offered

2) If there is no drawing, please advise the dimension/photos with dimension

3) Material information

4) Level and quantity information if possible.

About us:

Advantages of us:

1.Competitive price for injection mold

2.Quality, reliability and long product life.

3.Excellence design.

4.Rich experience in the design and manufacturer of plastic injection mould.

5.Customer's 2D, 3D drawing or samples are welcomed.

6.We will provide you the quotation forPlastic Injection Mould ASAP when we receive your inquiry.

7.you can use your own design or chose our design.

8.If you are not satisfied with the first sample, we will modify the mould until meet your satisfactory.

We will provide the plastic injection mould with the following details:

- Customer design service.

- Prototyping.

- Mold making.

- Manufacturing process control.

- Mold flow analysis service available!

- Reverse mold engineering.

- Customer molding & assembly.

- Cold runner mold and hot runner mold (MoldMaster, Incoe, Masterflow, LKM, Yudo system…etc)

| product name | Plastic injection mold |

| plastic material | HIPS ABS, PC, PP, PS, POM, PMMA,PE,AS,PPSN,PBT,PA66,PC/ABS.etc |

| Mould standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard, etc |

| Material main core and cavity insert | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13, etc |

| sureface treatment | powder coating, polishing, chrome plating, mirror polishing |

| Specification checking | Caliper, Quick checking tools, Needle gauge tools, Straightedge®ulatory teeth..ect. |

| injection machies equipments | According to product precision to choice the different model

80T,120T,250T,450T,800T injection machine |

| Inspection | 100% inspection by QC, QA before shipping. |

| Package | 1. inner plastic bags with foam, outer for cartoon or wooden cases with good protect;

2. according to customer's requirement |

| Applications | All kinds of cars spare part , machinery, home appliance, electronic products, medical devices, stationery, computers, power switches, miniature switches, architecture, commodity and A/V equipment, hardware and plastic molds, sports equipment and gifts, and more. |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG |

| deliver way | DHL, Fedex, TNT, UPS, DDU, by sea, by air..ect. |

| Gate | Cold runner,Yudo/DME/HASCO/Synventive Hot runner |

| quality contorl system | ISO9001: 2008, SGS, RoHS |

| Payment term | 50%down pay, balacne payment before shipping |

Factory Tour:

Welcome to visit our factory for sightseeing!

| Supplier Company Name | Dongguan Longeron-mold Technology Co;Ltd. |

| Made-in-China Supplier Member ID | Longeron-mold |

| Company Address | No.5 Qingzhang road(next to Qingxi bus station),Qingxitown Dongguan City,Guangdong province,China. |

| Contact Person | Susie Xu |

| Mobile Number | 86-18923633826 |

| Telephone Number | 86-769-87366628 |

| Website | Http://longeron-mold.en.made-in-China.com www.longeron-mold.com |

"Longeron"Co., Ltd. is specialized in all kinds of plastic injection moulds which is including Automotive parts mold(Mainly for car decorated mould, auto doors accessories injection mould, Auto ventilation tube injection. ), home appliance mould( mainly for TV plastic injections mold). At the meantime, We also have rich experience in medical, aerospace injection mold manufacturing.

Complex mold, precision mold is our strengths!

We' re pleased to get your Inquiry and we will come back to as soon as possible.

We stick to the principle of "quality first, service first, continuous improvement and innovation to meet the customers" for the management and "zero defect, zero complaints" as the quality objective.

To perfect our service, we provide the products with good quality at the reasonable price.

1. Showing you a "ONE STOP" service to you.

2. Our goal is to help you develop and produce your new project, and we will try best to reduce cost AS LESS AS POSSIBLE. We have 80% product are export to Europe and USA, and cooperation is very happy, hope we can servicing to you also. Please kindly review and contact me.

Advantages:

1. We are the manufacturer, our own mould factory, so we have competitive price.

2. Continuous service as support.

3. Diversified rich experiences skillful workers /Speicialized Designer.

4. Custom R&D program, coordination.

5. Long Life cycle and high quality.

6. One-stop service.

7. Complex mold, precision mold is our strengths!